October - Library - Central Queensland University

October - Library - Central Queensland University

October - Library - Central Queensland University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

32<br />

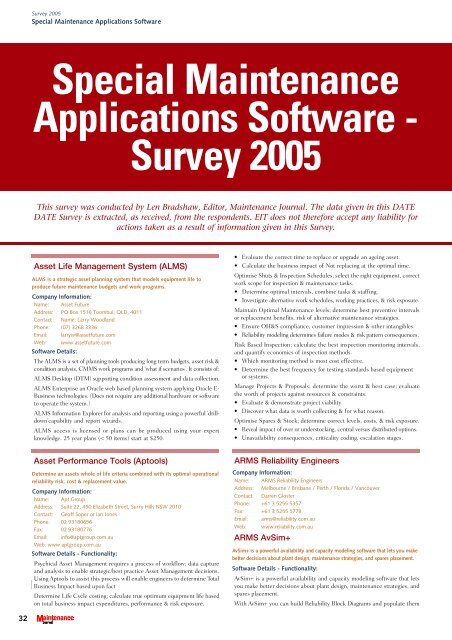

Survey 2005<br />

Special Maintenance Applications Software<br />

Special Maintenance<br />

Applications Software -<br />

S u rvey 2005<br />

This survey was conducted by Len Bradshaw, Editor, Maintenance Journal. The data given in this DATE<br />

DATE Survey is extracted, as received, from the respondents. EIT does not therefore accept any liability for<br />

actions taken as a result of information given in this Survey.<br />

Asset Life Management System (ALMS)<br />

ALMS is a strategic asset planning system that models equipment life to<br />

produce future maintenance budgets and work programs.<br />

Company Information:<br />

Name: Asset Future<br />

Address: PO Box 1516 Toombul, QLD, 4011<br />

Contact Name: Larry Woodland<br />

Phone: (07) 3268 3336<br />

Email: larryw@assetfuture.com<br />

Web: www.assetfuture.com<br />

Software Details:<br />

The ALMS is a set of planning tools producing long term budgets, asset risk &<br />

condition analysis, CMMS work programs and ‘what if scenarios’. It consists of:<br />

ALMS Desktop (DTM) supporting condition assessment and data collection.<br />

ALMS Enterprise an Oracle web based planning system applying Oracle E-<br />

Business technologies. (Does not require any additional hardware or software<br />

to operate the system.)<br />

ALMS Information Explorer for analysis and reporting using a powerful ‘drilldown’capability<br />

and report wizards.<br />

ALMS access is licensed or plans can be produced using your expert<br />

knowledge. 25 year plans (< 50 items) start at $250.<br />

Asset Performance Tools (Aptools)<br />

Determine an assets whole of life criteria combined with its optimal operational<br />

reliability risk, cost & replacement value.<br />

Company Information:<br />

Name: Apt Group<br />

Address: Suite 22, 450 Elizabeth Street, Surry Hills NSW 2010<br />

Contact: Geoff Soper or Ian Jones<br />

Phone: 02 93180656<br />

Fax: 02 93180776<br />

Email: info@aptgroup.com.au<br />

Web: www.aptgroup.com.au<br />

Software Details - Functionality:<br />

Psychical Asset Management requires a process of workflow; data capture<br />

and analysis to enable strategic/best practice Asset Management decisions.<br />

Using Aptools to assist this process will enable engineers to determine To t a l<br />

Business Impact based upon fact<br />

Determine Life Cycle costing; calculate true optimum equipment life based<br />

on total business impact expenditures, performance & risk exposure.<br />

• Evaluate the correct time to replace or upgrade an ageing asset.<br />

• Calculate the business impact of Not replacing at the optimal time.<br />

Optimise Shuts & Inspection Schedules; select the right equipment, correct<br />

work scope for inspection & maintenance tasks.<br />

• Determine optimal intervals, combine tasks & staffing.<br />

• Investigate alternative work schedules, working practices, & risk exposure.<br />

Maintain Optimal Maintenance levels; determine best preventive intervals<br />

or replacement benefits, risk of alternative maintenance strategies.<br />

• Ensure OH&S compliance, customer impression & other intangibles.<br />

• Reliability modeling determines failure modes & risk pattern consequences.<br />

Risk Based Inspection; calculate the best inspection monitoring intervals,<br />

and quantify economics of inspection methods.<br />

• Which monitoring method is most cost effective.<br />

• Determine the best frequency for testing standards based equipment<br />

or systems.<br />

Manage Projects & Proposals; determine the worst & best case; evaluate<br />

the worth of projects against resources & constraints.<br />

• Evaluate & demonstrate project viability.<br />

• Discover what data is worth collecting & for what reason.<br />

Optimise Spares & Stock; determine correct levels, costs, & risk exposure.<br />

• Reveal impact of over or understocking, central versus distributed options.<br />

• Unavailability consequences, criticality coding, escalation stages.<br />

ARMS Reliability Engineers<br />

Company Information:<br />

Name: ARMS Reliability Engineers<br />

Address: Melbourne / Brisbane / Perth / Florida / Vancouver<br />

Contact: Darren Gloster<br />

Phone: +61 3 5255 5357<br />

Fax: +61 3 5255 5778<br />

Email: arms@reliability.com.au<br />

Web: www.reliability.com.au<br />

ARMS AvSim+<br />

AvSim+ is a powerful availability and capacity modeling software that lets you make<br />

better decisions about plant design, maintenance strategies, and spares placement.<br />

Software Details - Functionality:<br />

AvSim+ is a powerful availability and capacity modeling software that lets<br />

you make better decisions about plant design, maintenance strategies, and<br />

spares placement.<br />

With AvSim+ you can build Reliability Block Diagrams and populate them