October - Library - Central Queensland University

October - Library - Central Queensland University

October - Library - Central Queensland University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The metric is calculated as follows:<br />

Total Overtime Hours for Week<br />

Overtime % = ----------------------------------------------------- X 100%<br />

Total Regular Hours Worked for Week<br />

Total Hours Worked on Emergencies<br />

Emergency % = ----------------------------------------------------- X 100%<br />

Total Hours Worked for the Week<br />

E v e ry eff o rt possible is re q u i red by each company employee to anticipate maintenance work re q u i rements as far in advance as<br />

possible if the Maintenance Department is to be efficient and effective. Fewer emergencies means the Maintenance Department<br />

can do more jobs with the same workforce, and everybody reaps the benefits.<br />

Unplanned Work Orders<br />

For the maintenance organization to be effective in the planning and scheduling of work, the work orders need to be planned in a<br />

timely manner. One way to measure this is to determine how many unplanned work orders are greater than one week old. This<br />

metrics gauges how well the Planner/Scheduler is staying on top of the planning workload.<br />

The metric is calculated as follows:<br />

Unplanned Work Orders = Number of Unplanned Work Orders Greater than Seven Days Old<br />

Craft Time Posted to Blanket Work Orders<br />

Many organizations find it convenient, particularly in the early stages of the work order system implementation, to cre a t e<br />

administrative devices to absorb craft time. These devises, collectively re f e rred to here as blanket orders, reduce the administrative<br />

labor required to assign and account for maintenance labor. However, they also proportionally reduce the resolution and thereby<br />

the value of the equipment history data collected by the work order system. Because Metric Calculations, Failure Analysis, and<br />

Engineered Maintenance activities all depend on the equipment history stored in the work order system, it is important that the use<br />

of blanket orders be limited initially and reduced to a minimum over time.<br />

The metric is calculated as follows:<br />

Total Craft Hours Posted to Blanket Orders<br />

Blanket W/O % = ----------------------------------------------------------- X 100%<br />

Total Craft Hours Posed to W/O System<br />

PdM Work Order Execution<br />

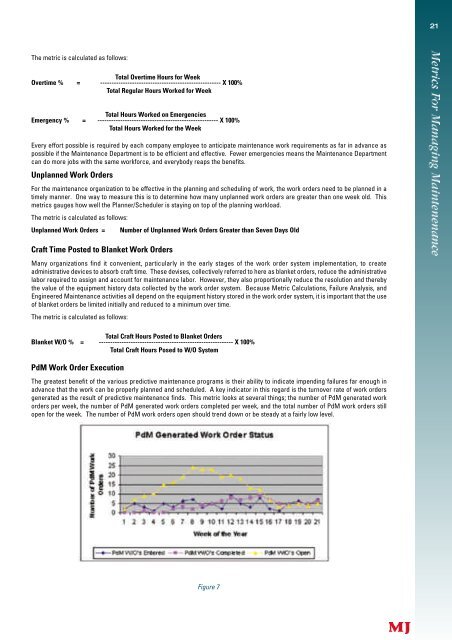

The greatest benefit of the various predictive maintenance programs is their ability to indicate impending failures far enough in<br />

advance that the work can be properly planned and scheduled. A key indicator in this regard is the turnover rate of work orders<br />

generated as the result of predictive maintenance finds. This metric looks at several things; the number of PdM generated work<br />

orders per week, the number of PdM generated work orders completed per week, and the total number of PdM work orders still<br />

open for the week. The number of PdM work orders open should trend down or be steady at a fairly low level.<br />

Figure 7<br />

21