hydrogen production from water using solar cells powered nafion ...

hydrogen production from water using solar cells powered nafion ...

hydrogen production from water using solar cells powered nafion ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

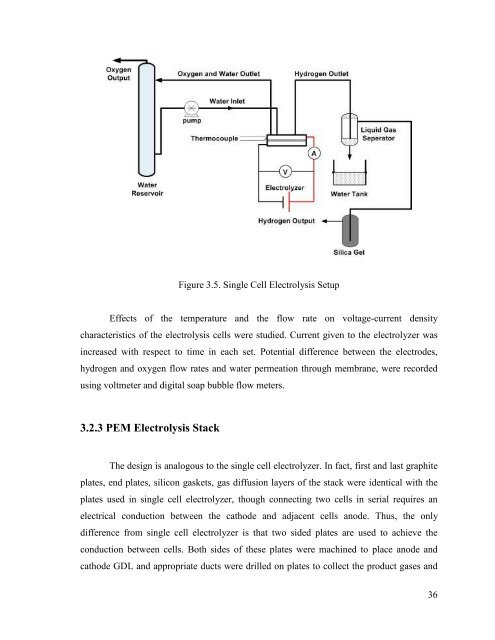

Figure 3.5. Single Cell Electrolysis Setup<br />

Effects of the temperature and the flow rate on voltage-current density<br />

characteristics of the electrolysis <strong>cells</strong> were studied. Current given to the electrolyzer was<br />

increased with respect to time in each set. Potential difference between the electrodes,<br />

<strong>hydrogen</strong> and oxygen flow rates and <strong>water</strong> permeation through membrane, were recorded<br />

<strong>using</strong> voltmeter and digital soap bubble flow meters.<br />

3.2.3 PEM Electrolysis Stack<br />

The design is analogous to the single cell electrolyzer. In fact, first and last graphite<br />

plates, end plates, silicon gaskets, gas diffusion layers of the stack were identical with the<br />

plates used in single cell electrolyzer, though connecting two <strong>cells</strong> in serial requires an<br />

electrical conduction between the cathode and adjacent <strong>cells</strong> anode. Thus, the only<br />

difference <strong>from</strong> single cell electrolyzer is that two sided plates are used to achieve the<br />

conduction between <strong>cells</strong>. Both sides of these plates were machined to place anode and<br />

cathode GDL and appropriate ducts were drilled on plates to collect the product gases and<br />

36