PhD Thesis_RuiMSMartins.pdf - RUN UNL

PhD Thesis_RuiMSMartins.pdf - RUN UNL

PhD Thesis_RuiMSMartins.pdf - RUN UNL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

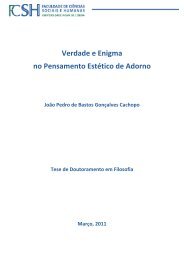

Fig. 1.23: RBS results of composition versus sputtering angle (using a hot and a “cold” target) [100].<br />

.......................................................................................................................................... 48<br />

Fig. 1.24: Grooves present in used sputtering targets; (a) Ni-Ti, (b) Ti, (c) Ni [101]. ....................... 49<br />

Fig. 1.25: Photograph of a microwrapper fabricated using a Ni-Ti graded film [22]. ........................ 50<br />

Fig. 1.26: RBS measurements; (a) initial 600 nm thick Ni-Ti layer deposited on the Si substrate,<br />

(b) Ni-Ti layer deposited on the Ni-rich Ni-Ti layer (Y-axis: atomic composition of Ni and Ti, X-<br />

axis: thickness of Ni-Ti layer) [22]. ...................................................................................... 50<br />

Fig. 1.27: The crystallization temperature of the Ni-Ti films increases with Ar working pressure for<br />

the same heating rate [115]. ................................................................................................. 53<br />

Fig. 1.28: Comparison of activation energies: open symbols are data from Ni-Ti films and closed<br />

symbols from bulk Ni-Ti (K: Kissinger’s method, A: Avrami’s method, and X: X-ray method)<br />

[105]. ................................................................................................................................. 53<br />

Fig. 1.29: DSC isothermal plots equiatomic Ni-Ti films (≈22 µm) released from a stainless steel<br />

substrate showing broadening of crystallization peaks and an increase in incubation times as the<br />

crystallization temperature is lowered [116]. ......................................................................... 54<br />

Fig. 1.30: TEM micrograph of one of the two surfaces of a Ni-Ti film crystallized at 430°C and<br />

quenched in liquid nitrogen after 25 min. It shows the microstructure resulting from surface<br />

nucleation of columnar grains (top) growing into remnant amorphous phase (bottom). The inset<br />

with a close-up of the interface reveals a grain size of approximately 1 µm [116]. ................... 54<br />

Fig. 1.31: Precipitation in the Ni-Ti matrix of Ti-rich Ni-Ti film (Ti-48.2at.%Ni) heat-treated for 1 h at<br />

various temperatures: (g) are Ti 2 Ni particles with random orientation; (□) are Ti 2 Ni precipitates<br />

with the same orientation as that of the matrix; (∆) are plate precipitates and oriented Ti 2 Ni<br />

precipitates; (•) are plate precipitates – d) high temperature form, e) low temperature form; (Ο)<br />

indicate no precipitates; (▲) indicate amorphous films [9]. .................................................... 56<br />

Fig. 1.32: GIXD patterns of Ni-Ti films during crystallization at an annealing temperature of 430ºC<br />

deposited on a Si(100) substrate at 70 mm – the indicated annealing time corresponds to the time<br />

when half a scan is completed [26]. ...................................................................................... 58<br />

Fig. 1.33: Crystallized phase fraction versus crystallization time for Ni-Ti films deposited directly on<br />

Si(100) wafers (h = 40 and 70 mm). The experimental data correspond to integrated peak<br />

intensities of Ni-Ti B2(110) and (200), the theoretical values are obtained by using the Johnson-<br />

Mehl-Avrami equation [26]. ................................................................................................ 58<br />

Fig. 1.34: Development of the B2(200) diffraction peak area during crystallization of the Ni-Ti films,<br />

deposited on Si(100) with and without an intermediate poly-Si layer; (a) Ni-Ti deposited at<br />

70 mm, (b) Ni-Ti deposited at 40 mm [26]. ........................................................................... 59<br />

Fig. 1.35: Schematic representation of oxidation of an equiatomic Ni-Ti alloy [125]. ...................... 62<br />

Fig. 1.36: Multi-layered structure seen in cross-section of a specimen oxidized at 750°C [126]. ....... 62<br />

Fig. 1.37: Schematic diagrams of the microstructural evolution of interfacial reaction layers of Ni-<br />

Ti/Si(100) annealed at 400-700°C for 30 min [130]. .............................................................. 65<br />

Fig. 1.38: Cross-sections of crystallized Ti-50.0at%Ni films with different thicknesses and<br />

strengthening mechanisms of films [136]. ............................................................................. 67<br />

Fig. 1.39: Residual stress and recovery stress for Ni-Ti films with different thicknesses [128]. ........ 68<br />

Fig. 1.40: Pole figures of Ni-Ti B2 phase nominally measured in the Bragg peaks B2(110) and<br />

B2(200); (a) Ti-52.2at%Ni film which was crystallized at 700°C for 1 h, (b) Ti-51.6 at%Ni film<br />

heat-treated at 400°C for 1 h (the film was sputtered at 350°C) [23]. ...................................... 72<br />

Fig. 1.41: Transformation temperature of the films as a function of Hf content [150]. ..................... 74<br />

Fig. 1.42: Room temperature XRD of Ni 50 Ti 50-x Hf x films after annealing at 550°C as a function of Hf<br />

content [150]. ..................................................................................................................... 74<br />

Fig. 2.1: General layout of ROBL (BM20) at ESRF. The X-ray optics in the first hutch (1) delivers<br />

monochromatic radiation either to the radiochemistry hutch (2) or to the MRH (3). A total of<br />

three cabins are available for beamline and experiments control [(4) control cabine for MRH] as<br />

well as for minor (non-radioactive) sample preparation and maintenance work. ...................... 78<br />

Fig. 2.2: Schematic layout of the ROBL optics [153]. ................................................................... 79<br />

xii