PhD Thesis_RuiMSMartins.pdf - RUN UNL

PhD Thesis_RuiMSMartins.pdf - RUN UNL

PhD Thesis_RuiMSMartins.pdf - RUN UNL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

In-situ XRD studies during growth of Ni-Ti SMA films and their complementary ex-situ characterization<br />

Recently, Robertson et al. [139] have conducted a study to seek further understanding<br />

of how processing and heat treatment can affect the texture in Ni-Ti bulk material, specifically<br />

by quantifying the texture of a variety of raw material forms, and to determine if annealing<br />

heat treatments can be utilized to change the strength and orientation of the texture in order to<br />

vary the mechanical response. They have shown that Ni-Ti does exhibit crystallographic<br />

orientation resulting from its forming and processing, which cannot be eliminated by<br />

annealing at high homologous temperatures up to ≈ 0.85 T m (with T m the melting<br />

temperature).<br />

Thus, due to the importance of the present topic, several researchers have studied the<br />

influence of cold work, annealing and precipitation kinetics during aging, on the martensitic<br />

transformation in Ni-Ti alloys.<br />

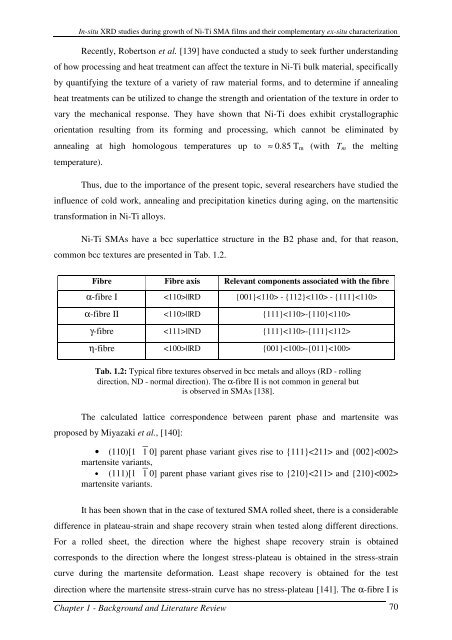

Ni-Ti SMAs have a bcc superlattice structure in the B2 phase and, for that reason,<br />

common bcc textures are presented in Tab. 1.2.<br />

Fibre Fibre axis Relevant components associated with the fibre<br />

α-fibre I ||RD {001} - {112} - {111}<br />

α-fibre II ||RD {111}-{110}<br />

γ-fibre ||ND {111}-{111}<br />

η-fibre ||RD {001}-{011}<br />

Tab. 1.2: Typical fibre textures observed in bcc metals and alloys (RD - rolling<br />

direction, ND - normal direction). The α-fibre II is not common in general but<br />

is observed in SMAs [138].<br />

The calculated lattice correspondence between parent phase and martensite was<br />

proposed by Miyazaki et al., [140]:<br />

• (110)[1 ⎺1 0] parent phase variant gives rise to {111} and {002}<br />

martensite variants,<br />

• (111)[1 ⎺1 0] parent phase variant gives rise to {210} and {210}<br />

martensite variants.<br />

It has been shown that in the case of textured SMA rolled sheet, there is a considerable<br />

difference in plateau-strain and shape recovery strain when tested along different directions.<br />

For a rolled sheet, the direction where the highest shape recovery strain is obtained<br />

corresponds to the direction where the longest stress-plateau is obtained in the stress-strain<br />

curve during the martensite deformation. Least shape recovery is obtained for the test<br />

direction where the martensite stress-strain curve has no stress-plateau [141]. The α-fibre I is<br />

Chapter 1 - Background and Literature Review 70