Performance Apparel Markets - Grado Zero Espace Srl

Performance Apparel Markets - Grado Zero Espace Srl

Performance Apparel Markets - Grado Zero Espace Srl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Performance</strong> <strong>Apparel</strong> <strong>Markets</strong>, 1st quarter 2006<br />

Seamless knitting and stitch-free technologies<br />

The range of end uses has<br />

expanded from lingerie to<br />

include gloves, sweaters,<br />

dresses, trousers and skirts<br />

By 2007 Santoni estimates<br />

that seamless underwear<br />

will account for 35% of the<br />

total market<br />

Polyamide microfibres are<br />

the most common yarns in<br />

seamless knitting and offer<br />

a number of benefits<br />

Nylstar produces a range<br />

of high performance<br />

microfibres developed for<br />

seamless knitting<br />

When seamless knitting was introduced by Shima Seiki in 1995, its<br />

applications were confined to the lingerie sector. Since then, the range<br />

of end uses has broadened out to include the production of gloves and<br />

sweaters, as well as dresses, trousers and skirts.<br />

In terms of market penetration, seamless knitting technology was<br />

estimated to be used by just 1% of underwear manufacturers globally<br />

in 1997. But by 2007, Santoni estimates, seamless underwear will<br />

account for as much as 35% of the total underwear market.<br />

YARNS FOR SEAMLESS KNITTING<br />

The most commonly used yarns in seamless knitting are polyamide<br />

microfibres. These high performance fibres result in garments which<br />

are breathable, quick drying, and durable through multiple home wash<br />

cycles.<br />

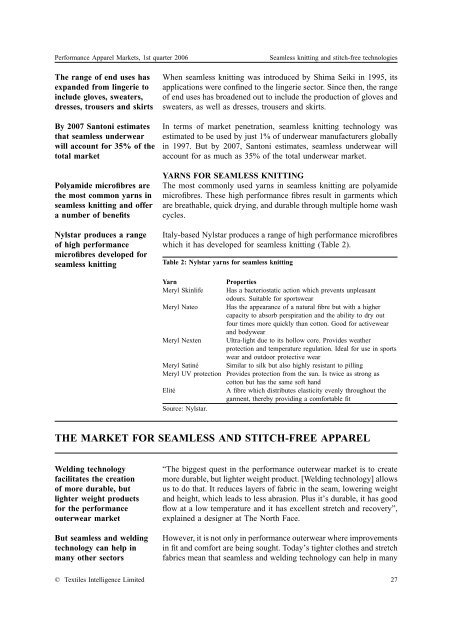

Italy-based Nylstar produces a range of high performance microfibres<br />

which it has developed for seamless knitting (Table 2).<br />

Table 2: Nylstar yarns for seamless knitting<br />

Yarn<br />

Properties<br />

Meryl Skinlife Has a bacteriostatic action which prevents unpleasant<br />

odours. Suitable for sportswear<br />

Meryl Nateo Has the appearance of a natural fibre but with a higher<br />

capacity to absorb perspiration and the ability to dry out<br />

four times more quickly than cotton. Good for activewear<br />

and bodywear<br />

Meryl Nexten Ultra-light due to its hollow core. Provides weather<br />

protection and temperature regulation. Ideal for use in sports<br />

wear and outdoor protective wear<br />

Meryl Satiné Similar to silk but also highly resistant to pilling<br />

Meryl UV protection Provides protection from the sun. Is twice as strong as<br />

cotton but has the same soft hand<br />

Elité<br />

A fibre which distributes elasticity evenly throughout the<br />

garment, thereby providing a comfortable fit<br />

Source: Nylstar.<br />

THE MARKET FOR SEAMLESS AND STITCH-FREE APPAREL<br />

Welding technology<br />

facilitates the creation<br />

of more durable, but<br />

lighter weight products<br />

for the performance<br />

outerwear market<br />

But seamless and welding<br />

technology can help in<br />

many other sectors<br />

“The biggest quest in the performance outerwear market is to create<br />

more durable, but lighter weight product. [Welding technology] allows<br />

us to do that. It reduces layers of fabric in the seam, lowering weight<br />

and height, which leads to less abrasion. Plus it’s durable, it has good<br />

flow at a low temperature and it has excellent stretch and recovery”,<br />

explained a designer at The North Face.<br />

However, it is not only in performance outerwear where improvements<br />

in fit and comfort are being sought. Today’s tighter clothes and stretch<br />

fabrics mean that seamless and welding technology can help in many<br />

© Textiles Intelligence Limited 27