Performance Apparel Markets - Grado Zero Espace Srl

Performance Apparel Markets - Grado Zero Espace Srl

Performance Apparel Markets - Grado Zero Espace Srl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Performance</strong> <strong>Apparel</strong> <strong>Markets</strong>, 1st quarter 2006<br />

Profile of Bemis: a leader in bonded seam technology<br />

High viscosity polyolefin<br />

film tapes are designed to<br />

eliminate the problem of<br />

seam puckering caused by<br />

shrinkage during wash<br />

cycles<br />

They are suitable for a<br />

number of applications<br />

Seam reinforcing tapes are<br />

designed to reinforce seams<br />

created by ultrasonic line<br />

bonding (USLB)<br />

USLB seams are weak and<br />

need reinforcement tapes<br />

PUCKER-FREE SEAM TAPE<br />

Pucker-free seam tapes are made from high viscosity polyolefin films.<br />

They are designed to eliminate the problem of seam puckering caused<br />

by shrinkage during wash cycles.<br />

The tapes are lightweight and rigid and have a uniform thickness and<br />

smooth edge, making them snag-free.<br />

Applications include front and back yokes, armhole side seams and<br />

sleeve seams.<br />

SEAM REINFORCING TAPES<br />

Seam reinforcing tapes are designed to reinforce seams created by<br />

ultrasonic bonding.<br />

Ultrasonically line bonded (USLB) seams are becoming more popular<br />

as they offer a way of producing a low profile, sleek and less abrasive<br />

seam, for which very little seam allowance is required in the fabric.<br />

USLB seams can be produced at the same rate as those made using<br />

traditional cut and sew methods. The downside, however, is that<br />

USLB seams are weak, they can be pulled apart easily, and they are<br />

not waterproof. For this reason, tapes must be used to reinforce USLB<br />

seams and make them waterproof. The seam reinforcing tapes are<br />

applied using hot air sealers.<br />

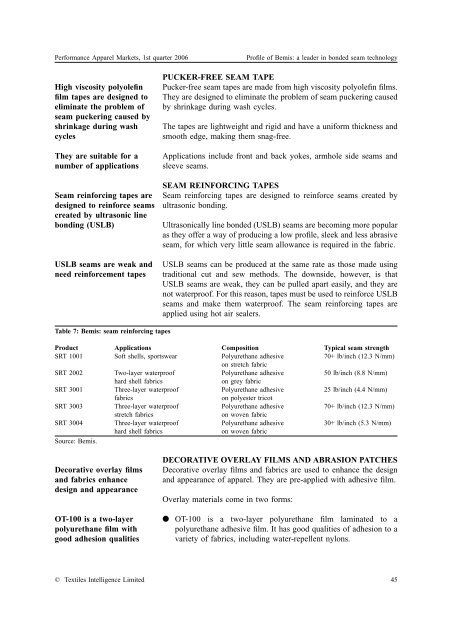

Table 7: Bemis: seam reinforcing tapes<br />

Product Applications Composition Typical seam strength<br />

SRT 1001 Soft shells, sportswear Polyurethane adhesive 70+ lb/inch (12.3 N/mm)<br />

on stretch fabric<br />

SRT 2002 Two-layer waterproof Polyurethane adhesive 50 lb/inch (8.8 N/mm)<br />

hard shell fabrics<br />

on grey fabric<br />

SRT 3001 Three-layer waterproof Polyurethane adhesive 25 lb/inch (4.4 N/mm)<br />

fabrics<br />

on polyester tricot<br />

SRT 3003 Three-layer waterproof Polyurethane adhesive 70+ lb/inch (12.3 N/mm)<br />

stretch fabrics<br />

on woven fabric<br />

SRT 3004 Three-layer waterproof Polyurethane adhesive 30+ lb/inch (5.3 N/mm)<br />

hard shell fabrics<br />

on woven fabric<br />

Source: Bemis.<br />

Decorative overlay films<br />

and fabrics enhance<br />

design and appearance<br />

OT-100 is a two-layer<br />

polyurethane film with<br />

good adhesion qualities<br />

DECORATIVE OVERLAY FILMS AND ABRASION PATCHES<br />

Decorative overlay films and fabrics are used to enhance the design<br />

and appearance of apparel. They are pre-applied with adhesive film.<br />

Overlay materials come in two forms:<br />

● OT-100 is a two-layer polyurethane film laminated to a<br />

polyurethane adhesive film. It has good qualities of adhesion to a<br />

variety of fabrics, including water-repellent nylons.<br />

© Textiles Intelligence Limited 45