High Speed Machining Precision Tooling - Indobiz.biz

High Speed Machining Precision Tooling - Indobiz.biz

High Speed Machining Precision Tooling - Indobiz.biz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Figure 1. The transform part<br />

zero software feature was<br />

designed to minimize steps.<br />

Figure 2. Workpiece surface contact point + tool vector<br />

EXAMPLE: G01 X10.Y10.Z10. I0.5J0.5K0.707106<br />

would be equivalent to: G01 X10.Y10.Z10.B45.C45<br />

Benefits of Tool<br />

Vector Input feature:<br />

• Program is machine<br />

independent<br />

• Control software computes<br />

machine angles and<br />

positions<br />

• Simplifi es post-processor<br />

1.<br />

2.<br />

3.<br />

4.<br />

Create a Rotary Position<br />

data block<br />

Set the Transform Part<br />

Zero fi eld to YES<br />

Insert a Transform Plane<br />

Reference Point data<br />

block<br />

Specify the distance to<br />

shift the part zero relative<br />

to the original setup<br />

Redundancy in Posting a Five-Axis<br />

Program<br />

Each time you refi xture, you have to waste<br />

valuable time re-entering the distance<br />

from part zero to the center lines of<br />

rotation and then repost the program. If<br />

your control has a software feature such<br />

as tool center point management, you<br />

only have to post the program once and<br />

machine the part—no matter where it is<br />

in relation to the center lines of rotation<br />

on the machine.<br />

Tool center point management solves<br />

the problem for CAM software. The CAM<br />

programmer generates the toolpath<br />

based on the part model’s zero location.<br />

Therefore, you can post the program<br />

independent of where the stock is<br />

fi xtured on the table—a substantial time<br />

saver for a fi ve-axis part.<br />

Complex and Diffi cult Post Processors<br />

CAM systems generally use tool vectors<br />

to generate the toolpath. To make<br />

programs independent of the machine’s<br />

rotary confi guration and to simplify the<br />

post processor, there is a tool vector<br />

input control software feature for fi veaxis<br />

machining centers (see Figure 2).<br />

This feature lets you specify the tool tip<br />

location relative to the workpiece and<br />

the tool axis vector instead of using<br />

address letters to specify the B and C<br />

axes angles. Executing the program is<br />

much faster because the post doesn’t<br />

need the machine confi guration and the<br />

centerline of the rotary axes.<br />

Marks on the Part<br />

Simultaneous fi ve-axis toolpaths can<br />

result in odd looping rotary moves<br />

that leave marks on the part when the<br />

program is interpolated by the machine’s<br />

control. One solution is a feature called<br />

toolpath linearization, which is specifi c to<br />

fi ve-axis, G-code programs. It eliminates<br />

the many line segments in the form of<br />

XYZBC moves that a CAM system uses<br />

to create a smooth part.<br />

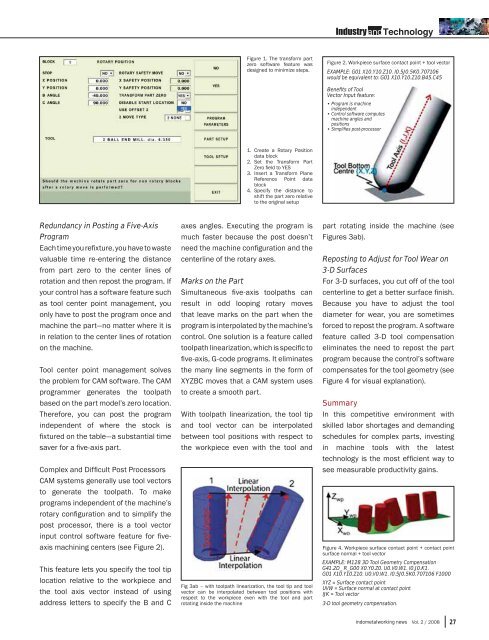

With toolpath linearization, the tool tip<br />

and tool vector can be interpolated<br />

between tool positions with respect to<br />

the workpiece even with the tool and<br />

Fig 3ab – with toolpath linearization, the tool tip and tool<br />

vector can be interpolated between tool positions with<br />

respect to the workpiece even with the tool and part<br />

rotating inside the machine<br />

part rotating inside the machine (see<br />

Figures 3ab).<br />

Reposting to Adjust for Tool Wear on<br />

3-D Surfaces<br />

For 3-D surfaces, you cut off of the tool<br />

centerline to get a better surface fi nish.<br />

Because you have to adjust the tool<br />

diameter for wear, you are sometimes<br />

forced to repost the program. A software<br />

feature called 3-D tool compensation<br />

eliminates the need to repost the part<br />

program because the control’s software<br />

compensates for the tool geometry (see<br />

Figure 4 for visual explanation).<br />

Summary<br />

In this competitive environment with<br />

skilled labor shortages and demanding<br />

schedules for complex parts, investing<br />

in machine tools with the latest<br />

technology is the most effi cient way to<br />

see measurable productivity gains.<br />

Figure 4. Workpiece surface contact point + contact point<br />

surface normal + tool vector<br />

EXAMPLE: M128 3D Tool Geometry Compensation<br />

G41.2D_ R_G00 X0.Y0.Z0. U0.V0.W1. I0.J0.K1.<br />

G01 X10.Y10.Z10. U0.V0.W1. I0.5J0.5K0.707106 F1000<br />

XYZ = Surface contact point<br />

UVW = Surface normal at contact point<br />

IJK = Tool vector<br />

3-D tool geometry compensation.<br />

indometalworking news Vol. 2 / 2008 27