n o v/d e c • 2 0 0 8 - Subscribe

n o v/d e c • 2 0 0 8 - Subscribe

n o v/d e c • 2 0 0 8 - Subscribe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

50<br />

» pqi<br />

Direct to Substrate Trend --<br />

One Paint That Does the Job of Two<br />

Most professional painters have subscribed to the fact<br />

that choosing the right paint and pursuing proper<br />

surface preparation are critical steps in delivering a<br />

quality finish and minimizing pre-mature paint failures. In many<br />

cases, a suitable primer has to be used. Today’s primers are<br />

uniquely optimized to deliver adhesion to various surfaces, or<br />

to seal surfaces and block specific stains. Recently, we see<br />

advances that allow both primer and topcoat attributes to<br />

be wound into one package. This new trend is sometimes<br />

referred to as Direct to Substrate (DTS). We will show that the<br />

perfect finish, which resulted from a select primer plus 2-coats<br />

of a quality topcoat, can now be replaced by 2-coats of a<br />

quality DTS. The value proposition for professional painters<br />

and consumers alike is straightforward – one less coat (labor<br />

plus material) needs to be applied!<br />

On using primers: Today’s primers are optimized to deliver<br />

superior performance on selective surfaces. Consumers and<br />

contractors alike are fairly familiar with some of the primers<br />

on the market – e.g. drywall primers (for painting over fresh<br />

drywall); stain blocking primers (for blocking tannin stains in<br />

wood); and even metal primers (for inhibiting corrosion in<br />

applications over bare metal).<br />

Primers are designed to serve many purposes. They seal<br />

the substrate to be painted allowing for more efficient and<br />

uniform coverage with a topcoat. Primers also serve as a<br />

tie layer – providing optimum adhesion to the substrate and<br />

providing a compatible surface for the topcoat to stick. As<br />

new substrates and building practices evolve, we see primers<br />

evolving to enable a desired effect – for example, helping to<br />

accentuate the smoothness or roughness of a surface. And<br />

as we mentioned above, primers are also optimized to block<br />

stains (particularly tannins in wood).<br />

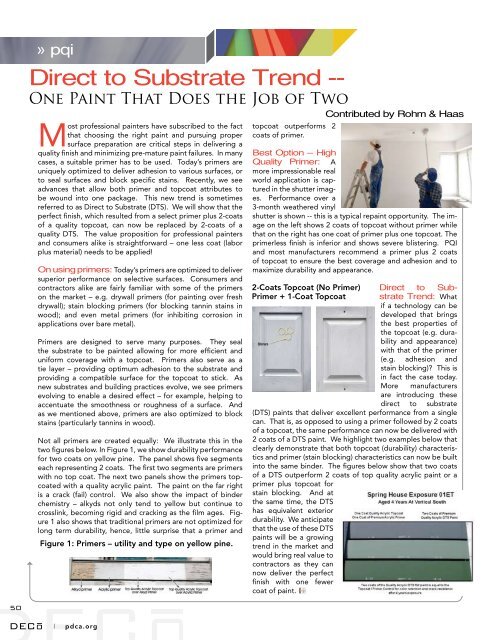

Not all primers are created equally: We illustrate this in the<br />

two figures below. In Figure 1, we show durability performance<br />

for two coats on yellow pine. The panel shows five segments<br />

each representing 2 coats. The first two segments are primers<br />

with no top coat. The next two panels show the primers topcoated<br />

with a quality acrylic paint. The paint on the far right<br />

is a crack (fail) control. We also show the impact of binder<br />

chemistry – alkyds not only tend to yellow but continue to<br />

crosslink, becoming rigid and cracking as the film ages. Figure<br />

1 also shows that traditional primers are not optimized for<br />

long term durability, hence, little surprise that a primer and<br />

Figure 1: Primers – utility and type on yellow pine.<br />

| pdca.org<br />

Contributed by Rohm & Haas<br />

topcoat outperforms 2<br />

coats of primer.<br />

Best Option – High<br />

Quality Primer: A<br />

more impressionable real<br />

world application is captured<br />

in the shutter images.<br />

Performance over a<br />

3-month weathered vinyl<br />

shutter is shown -- this is a typical repaint opportunity. The image<br />

on the left shows 2 coats of topcoat without primer while<br />

that on the right has one coat of primer plus one topcoat. The<br />

primerless finish is inferior and shows severe blistering. PQI<br />

and most manufacturers recommend a primer plus 2 coats<br />

of topcoat to ensure the best coverage and adhesion and to<br />

maximize durability and appearance.<br />

2-Coats Topcoat (No Primer)<br />

Primer + 1-Coat Topcoat<br />

Direct to Substrate<br />

Trend: What<br />

if a technology can be<br />

developed that brings<br />

the best properties of<br />

the topcoat (e.g. durability<br />

and appearance)<br />

with that of the primer<br />

(e.g. adhesion and<br />

stain blocking)? This is<br />

in fact the case today.<br />

More manufacturers<br />

are introducing these<br />

direct to substrate<br />

(DTS) paints that deliver excellent performance from a single<br />

can. That is, as opposed to using a primer followed by 2 coats<br />

of a topcoat, the same performance can now be delivered with<br />

2 coats of a DTS paint. We highlight two examples below that<br />

clearly demonstrate that both topcoat (durability) characteristics<br />

and primer (stain blocking) characteristics can now be built<br />

into the same binder. The figures below show that two coats<br />

of a DTS outperform 2 coats of top quality acrylic paint or a<br />

primer plus topcoat for<br />

stain blocking. And at<br />

the same time, the DTS<br />

has equivalent exterior<br />

durability. We anticipate<br />

that the use of these DTS<br />

paints will be a growing<br />

trend in the market and<br />

would bring real value to<br />

contractors as they can<br />

now deliver the perfect<br />

finish with one fewer<br />

coat of paint.