You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Standard Bearings<br />

which are fixed, Eccentric type (E), adjustable and Double Eccentric type (DE)* 5 which have sufficient adjustment to<br />

enable a carriage to be disengaged from the Slide (see application drawing on page 8).<br />

All Through Hole Fixing types are available in a Controlled Height version (CH)* 7 which minimises variation between<br />

Bearings in respect of the important 'B1' dimension. This may be desirable in some high precision applications.<br />

The Blind Hole Fixing type (BH) allows mounting into a solid machine base where through mounting holes are not<br />

possible, or where the thickness of the mounting plate is too great (see application drawings on page 16). The Blind Hole<br />

Fixing type is also useful where adjustment from the front is preferred or where access to the opposite side of the mounting<br />

hole is restricted. They are available in Concentric type (C) which are fixed, or Eccentric type (E) * 6 which are<br />

adjustable.<br />

All Bearings are greased for life internally. Customers are strongly recommended to provide lubrication to the interface<br />

between Bearings and Slide by specifying Hepco Cap Seals which fit over the bearings, or by using Hepco Lubricators.<br />

Lubrication greatly increases load capacity and life.<br />

Assembled<br />

Systems<br />

P 54-57<br />

XYZ<br />

+ABC<br />

123<br />

Calculations<br />

P58-62<br />

See Application Examples on pages 8-16<br />

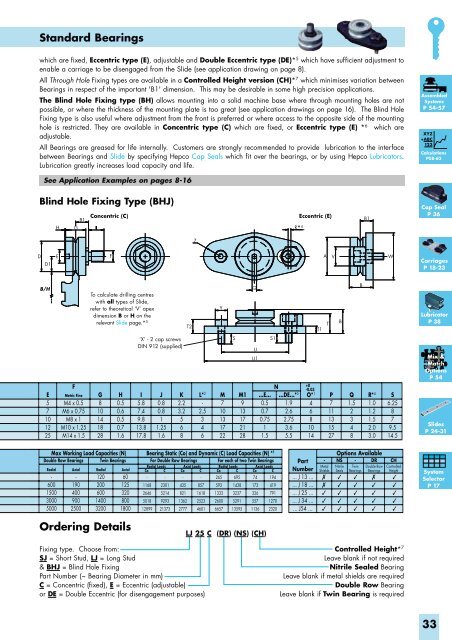

Blind Hole Fixing Type (BHJ)<br />

Concentric (C)<br />

B1<br />

H G<br />

Eccentric (E)<br />

B1<br />

Cap Seal<br />

P 36<br />

Z<br />

D<br />

D1<br />

E<br />

F<br />

A<br />

V<br />

W<br />

Carriages<br />

P 18-23<br />

B/H<br />

To calculate drilling centres<br />

with all types of Slide,<br />

refer to theoretical ‘V’ apex<br />

dimension B or H on the<br />

relevant Slide page.* 5<br />

T2<br />

Y<br />

Q<br />

T1<br />

T<br />

B<br />

B<br />

Lubricator<br />

P 38<br />

E<br />

5<br />

7<br />

10<br />

12<br />

25<br />

F<br />

Metric Fine<br />

M4 x 0.5<br />

M6 x 0.75<br />

M8 x 1<br />

M10 x 1.25<br />

M14 x 1.5<br />

G<br />

8<br />

10<br />

14<br />

18<br />

28<br />

H<br />

0.5<br />

0.6<br />

0.5<br />

0.7<br />

1.6<br />

‘X’ - 2 cap screws<br />

DIN 912 (supplied)<br />

I<br />

5.8<br />

7.4<br />

9.8<br />

13.8<br />

17.8<br />

J<br />

0.8<br />

0.8<br />

1<br />

1.25<br />

1.6<br />

K<br />

2.2<br />

3.2<br />

5<br />

6<br />

8<br />

L* 2<br />

-<br />

2.5<br />

3<br />

4<br />

6<br />

M<br />

7<br />

10<br />

13<br />

17<br />

22<br />

S<br />

M1<br />

9<br />

13<br />

17<br />

21<br />

28<br />

U<br />

U1<br />

...E...<br />

0.5<br />

0.7<br />

0.75<br />

1<br />

1.5<br />

S1<br />

N<br />

+0<br />

-0.03<br />

...DE...* 5<br />

1.9<br />

2.6<br />

2.75<br />

3.6<br />

5.5<br />

O* 1<br />

4<br />

6<br />

8<br />

10<br />

14<br />

P<br />

7<br />

11<br />

13<br />

15<br />

27<br />

Q<br />

1.5<br />

2<br />

3<br />

4<br />

8<br />

R* 4<br />

1.0<br />

1.2<br />

1.5<br />

2.0<br />

3.0<br />

S<br />

6.25<br />

8<br />

7<br />

9.5<br />

14.5<br />

Mix &<br />

Match<br />

Options<br />

P 54<br />

Slides<br />

P 24-31<br />

Max Working Load Capacities (N) Bearing Static (Co) and Dynamic (C) Load Capacities (N) * 8<br />

Double Row Bearings Twin Bearings<br />

For Double Row Bearings<br />

For each of two Twin Bearings<br />

Radial<br />

Axial<br />

Radial Axial<br />

Radial Loads<br />

Axial Loads<br />

Radial Loads<br />

Axial Loads<br />

Co C Co C Co C Co C<br />

-<br />

600<br />

1500<br />

3000<br />

5000<br />

-<br />

190<br />

400<br />

900<br />

2500<br />

120<br />

200<br />

600<br />

1400<br />

3200<br />

60<br />

125<br />

320<br />

800<br />

1800<br />

-<br />

1168<br />

2646<br />

5018<br />

12899<br />

-<br />

2301<br />

5214<br />

9293<br />

21373<br />

-<br />

435<br />

821<br />

1362<br />

2777<br />

-<br />

857<br />

1618<br />

2523<br />

4601<br />

265<br />

593<br />

1333<br />

2600<br />

6657<br />

695<br />

1438<br />

3237<br />

5291<br />

13595<br />

74<br />

173<br />

326<br />

557<br />

1136<br />

194<br />

419<br />

791<br />

1270<br />

2320<br />

Part<br />

Number<br />

... J 13 ...<br />

... J 18 ...<br />

... J 25 ...<br />

... J 34 ...<br />

... J54 ...<br />

-<br />

Metal<br />

Shields<br />

✗<br />

✗<br />

✓<br />

✓<br />

✓<br />

Options Available<br />

NS<br />

Nitrile<br />

Seals<br />

✓<br />

✓<br />

✓<br />

✓<br />

✓<br />

-<br />

Twin<br />

Bearings<br />

✓<br />

✓<br />

✓<br />

✓<br />

✓<br />

DR<br />

Double Row<br />

Bearings<br />

✗<br />

✓<br />

✓<br />

✓<br />

✓<br />

CH<br />

Controlled<br />

Height<br />

✓<br />

✓<br />

✓<br />

✓<br />

✓<br />

System<br />

Selector<br />

P 17<br />

Ordering Details<br />

LJ 25 C<br />

(DR) (NS) (CH)<br />

Fixing type. Choose from:<br />

SJ = Short Stud, LJ = Long Stud<br />

& BHJ = Blind Hole Fixing<br />

Part Number (~ Bearing Diameter in mm)<br />

C = Concentric (fixed), E = Eccentric (adjustable)<br />

or DE = Double Eccentric (for disengagement purposes)<br />

Controlled Height* 7<br />

Leave blank if not required<br />

Nitrile Sealed Bearing<br />

Leave blank if metal shields are required<br />

Double Row Bearing<br />

Leave blank if Twin Bearing is required<br />

33