Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cap Wipers<br />

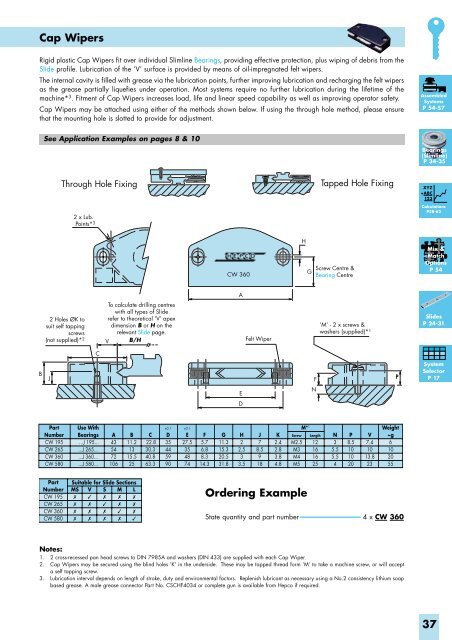

Rigid plastic Cap Wipers fit over individual Slimline Bearings, providing effective protection, plus wiping of debris from the<br />

Slide profile. Lubrication of the ‘V’ surface is provided by means of oil-impregnated felt wipers.<br />

The internal cavity is filled with grease via the lubrication points, further improving lubrication and recharging the felt wipers<br />

as the grease partially liquefies under operation. Most systems require no further lubrication during the lifetime of the<br />

machine* 3 . Fitment of Cap Wipers increases load, life and linear speed capability as well as improving operator safety.<br />

Cap Wipers may be attached using either of the methods shown below. If using the through hole method, please ensure<br />

that the mounting hole is slotted to provide for adjustment.<br />

Assembled<br />

Systems<br />

P 54-57<br />

See Application Examples on pages 8 & 10<br />

Bearings<br />

(Slimline)<br />

P 34-35<br />

Through Hole Fixing<br />

2 x Lub.<br />

Points* 3<br />

Tapped Hole Fixing<br />

XYZ<br />

+ABC<br />

123<br />

Calculations<br />

P58-62<br />

CW 360<br />

H<br />

G<br />

Screw Centre &<br />

Bearing Centre<br />

Mix &<br />

Match<br />

Options<br />

P 54<br />

A<br />

2 Holes ØK to<br />

suit self tapping<br />

screws<br />

(not supplied)* 2<br />

To calculate drilling centres<br />

with all types of Slide<br />

refer to theoretical ‘V’ apex<br />

dimension B or H on the<br />

relevant Slide page.<br />

V B/H<br />

Felt Wiper<br />

‘M’ - 2 x screws &<br />

washers (supplied)* 1<br />

Slides<br />

P 24-31<br />

B J<br />

C<br />

F<br />

P<br />

System<br />

Selector<br />

P 17<br />

E<br />

N<br />

D<br />

Part<br />

Number<br />

CW 195<br />

CW 265<br />

CW 360<br />

CW 580<br />

Use With<br />

Bearings<br />

...J 195...<br />

...J 265...<br />

...J 360...<br />

...J 580...<br />

A<br />

43<br />

54<br />

72<br />

106<br />

B<br />

11.2<br />

13<br />

15.5<br />

25<br />

C<br />

22.8<br />

30.3<br />

40.8<br />

63.3<br />

±0.1<br />

D<br />

35<br />

44<br />

59<br />

90<br />

±0.1<br />

E<br />

27.5<br />

35<br />

48<br />

74<br />

F<br />

5.7<br />

6.8<br />

8.3<br />

14.3<br />

G<br />

11.3<br />

15.3<br />

20.5<br />

31.8<br />

H<br />

2<br />

2.5<br />

3<br />

3.5<br />

J<br />

7<br />

8.5<br />

9<br />

18<br />

K<br />

2.4<br />

2.8<br />

3.8<br />

4.8<br />

Screw<br />

M2.5<br />

M3<br />

M4<br />

M5<br />

M* 1<br />

Length<br />

12<br />

16<br />

16<br />

25<br />

N<br />

3<br />

5.5<br />

5.5<br />

4<br />

P<br />

8.5<br />

10<br />

10<br />

20<br />

V<br />

7.4<br />

10<br />

13.8<br />

23<br />

Weight<br />

~g<br />

6<br />

10<br />

20<br />

55<br />

Part<br />

Number<br />

CW 195<br />

CW 265<br />

CW 360<br />

CW 580<br />

Suitable for Slide Sections<br />

MS<br />

✗<br />

✗<br />

✗<br />

✗<br />

V<br />

✓<br />

✗<br />

✗<br />

✗<br />

S<br />

✗<br />

✓<br />

✗<br />

✗<br />

M<br />

✗<br />

✗<br />

✓<br />

✗<br />

L<br />

✗<br />

✗<br />

✗<br />

✓<br />

Ordering Example<br />

State quantity and part number 4 x CW 360<br />

Notes:<br />

1. 2 cross-recessed pan head screws to DIN 7985A and washers (DIN 433) are supplied with each Cap Wiper.<br />

2. Cap Wipers may be secured using the blind holes ‘K’ in the underside. These may be tapped thread form ‘M’ to take a machine screw, or will accept<br />

a self tapping screw.<br />

3. Lubrication interval depends on length of stroke, duty and environmental factors. Replenish lubricant as necessary using a No.2 consistency lithium soap<br />

based grease. A male grease connector Part No. CSCHF4034 or complete gun is available from Hepco if required.<br />

37