Model No.PB - Sanyo Denki America, Inc.

Model No.PB - Sanyo Denki America, Inc.

Model No.PB - Sanyo Denki America, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

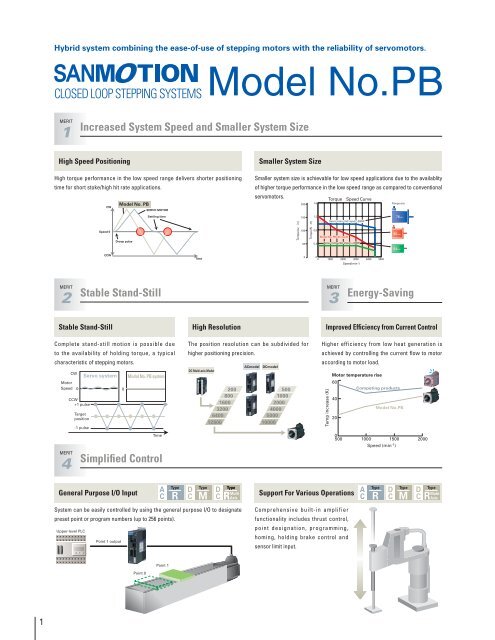

Hybrid system combining the ease-of-use of stepping motors with the reliability of servomotors.<br />

CLOSED LOOP STEPPING SYSTEMS <strong>Model</strong> <strong>No</strong>.<strong>PB</strong><br />

MERIT<br />

1<br />

<strong>Inc</strong>reased System Speed and Smaller System Size<br />

High Speed Positioning<br />

High torque performance in the low speed range delivers shorter positioning<br />

time for short stoke/high hit rate applications.<br />

CW<br />

<strong>Model</strong> <strong>No</strong>. <strong>PB</strong><br />

SERVO MOTOR<br />

Smaller System Size<br />

Smaller system size is achievable for low speed applications due to the availablity<br />

of higher torque performance in the low speed range as compared to conventional<br />

servomotors.<br />

TorqueSpeed Curve<br />

200 1.6<br />

Flange size<br />

Speed 0<br />

Droop pulse<br />

Settling time<br />

Torque(ozin)<br />

150<br />

100<br />

50<br />

Torque(Nm)<br />

1.2<br />

0.8<br />

0.4<br />

Servo motor (AC input) –300W<br />

<strong>Model</strong> <strong>No</strong>. <strong>PB</strong> (AC input)<br />

Servo motor (AC input) – 100W<br />

76mm<br />

60mm<br />

54mm<br />

CCW<br />

Time<br />

0<br />

0<br />

0 1000 2000 3000 4000 5000<br />

Speed(min -1 )<br />

MERIT<br />

2<br />

Stable Stand-Still<br />

MERIT<br />

3<br />

Energy-Saving<br />

Stable Stand-Still<br />

Complete stand-still motion is possible due<br />

to the availability of holding torque, a typical<br />

characteristic of stepping motors.<br />

MERIT<br />

4<br />

CW<br />

CCW<br />

+1 pulse<br />

Target<br />

position<br />

-1 pulse<br />

Servo system<br />

Motor<br />

Speed 0<br />

0<br />

<strong>Model</strong> <strong>No</strong>. <strong>PB</strong> system<br />

Time<br />

Simplified Control<br />

High Resolution<br />

The position resolution can be subdivided for<br />

higher positioning precision.<br />

DC Multi-axis <strong>Model</strong><br />

200<br />

800<br />

1600<br />

3200<br />

6400<br />

12800<br />

ACmodel DCmodel<br />

500<br />

1000<br />

2000<br />

4000<br />

5000<br />

10000<br />

Improved Efficiency from Current Control<br />

Higher efficiency from low heat generation is<br />

achieved by controlling the current flow to motor<br />

according to motor load.<br />

Temp increase (K)<br />

Motor temperature rise<br />

60<br />

40<br />

20<br />

Competing products<br />

0 500 1000<br />

<strong>Model</strong> <strong>No</strong>.<strong>PB</strong><br />

1500 2000<br />

Speed (min -1 )<br />

General Purpose I/O Input<br />

A<br />

C<br />

Type<br />

R<br />

D C<br />

Type<br />

M<br />

D C<br />

Type<br />

Multi<br />

Axis<br />

R<br />

Support For Various Operations<br />

A<br />

C<br />

Type<br />

R<br />

D C<br />

Type<br />

M<br />

D C<br />

Type<br />

R<br />

Multi<br />

Axis<br />

System can be easily controlled by using the general purpose I/O to designate<br />

preset point or program numbers (up to 256 points).<br />

Upper-level PLC<br />

Point 1 output<br />

Comprehensive built-in amplifier<br />

functionality includes thrust control,<br />

point designation, programming,<br />

homing, holding brake control and<br />

sensor limit input.<br />

Point 1<br />

Point 0<br />

1