INSTALLATION INSTRUCTIONS - Lennox

INSTALLATION INSTRUCTIONS - Lennox

INSTALLATION INSTRUCTIONS - Lennox

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Planned Service<br />

A service technician should check the following items during<br />

an annual inspection. Power to the unit must be shut off<br />

for safety.<br />

Fresh air grilles and louvers (on the unit and in the room<br />

where the furnace is installed) − Must be open and unobstructed<br />

to provide combustion air.<br />

Burners − Must be inspected for rust, dirt, or signs of water.<br />

Vent pipe − Must be inspected for signs of water, cracked,<br />

damaged or sagging pipe, or disconnected joints.<br />

Unit appearance − Must be inspected for rust, dirt, signs<br />

of water, burnt or damaged wires, or components.<br />

Blower access door − Must be properly in place and provide<br />

a seal between the return air and the room where the<br />

furnace is installed.<br />

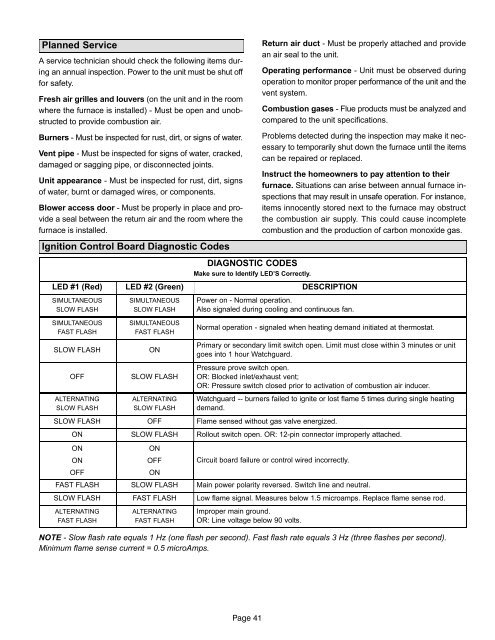

Ignition Control Board Diagnostic Codes<br />

DIAGNOSTIC CODES<br />

Make sure to Identify LED’S Correctly.<br />

LED #1 (Red) LED #2 (Green) DESCRIPTION<br />

SIMULTANEOUS<br />

SLOW FLASH<br />

SIMULTANEOUS<br />

FAST FLASH<br />

SLOW FLASH<br />

OFF<br />

ALTERNATING<br />

SLOW FLASH<br />

SIMULTANEOUS<br />

SLOW FLASH<br />

SIMULTANEOUS<br />

FAST FLASH<br />

ON<br />

SLOW FLASH<br />

ALTERNATING<br />

SLOW FLASH<br />

Return air duct − Must be properly attached and provide<br />

an air seal to the unit.<br />

Operating performance − Unit must be observed during<br />

operation to monitor proper performance of the unit and the<br />

vent system.<br />

Combustion gases − Flue products must be analyzed and<br />

compared to the unit specifications.<br />

Problems detected during the inspection may make it necessary<br />

to temporarily shut down the furnace until the items<br />

can be repaired or replaced.<br />

Instruct the homeowners to pay attention to their<br />

furnace. Situations can arise between annual furnace inspections<br />

that may result in unsafe operation. For instance,<br />

items innocently stored next to the furnace may obstruct<br />

the combustion air supply. This could cause incomplete<br />

combustion and the production of carbon monoxide gas.<br />

Power on − Normal operation.<br />

Also signaled during cooling and continuous fan.<br />

Normal operation − signaled when heating demand initiated at thermostat.<br />

Primary or secondary limit switch open. Limit must close within 3 minutes or unit<br />

goes into 1 hour Watchguard.<br />

Pressure prove switch open.<br />

OR: Blocked inlet/exhaust vent;<br />

OR: Pressure switch closed prior to activation of combustion air inducer.<br />

Watchguard −− burners failed to ignite or lost flame 5 times during single heating<br />

demand.<br />

SLOW FLASH OFF Flame sensed without gas valve energized.<br />

ON SLOW FLASH Rollout switch open. OR: 12-pin connector improperly attached.<br />

ON<br />

ON<br />

ON<br />

OFF Circuit board failure or control wired incorrectly.<br />

OFF<br />

ON<br />

FAST FLASH SLOW FLASH Main power polarity reversed. Switch line and neutral.<br />

SLOW FLASH FAST FLASH Low flame signal. Measures below 1.5 microamps. Replace flame sense rod.<br />

ALTERNATING<br />

FAST FLASH<br />

ALTERNATING<br />

FAST FLASH<br />

Improper main ground.<br />

OR: Line voltage below 90 volts.<br />

NOTE − Slow flash rate equals 1 Hz (one flash per second). Fast flash rate equals 3 Hz (three flashes per second).<br />

Minimum flame sense current = 0.5 microAmps.<br />

Page 41