CATALOGUE - MEDIPRO

CATALOGUE - MEDIPRO

CATALOGUE - MEDIPRO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

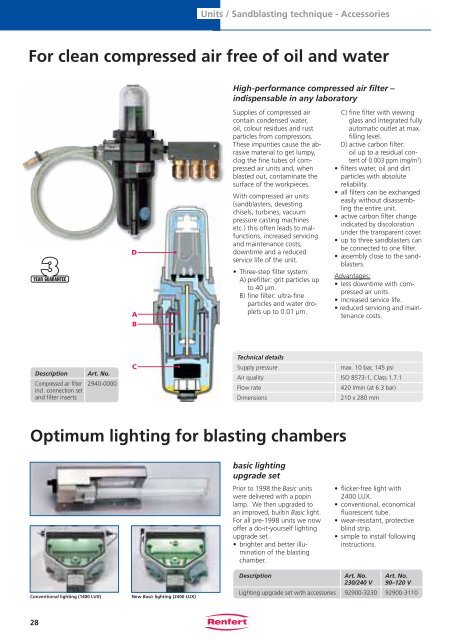

Units / Sandblasting technique - Accessories<br />

For clean compressed air free of oil and water<br />

High-performance compressed air filter –<br />

indispensable in any laboratory<br />

D<br />

A<br />

B<br />

Supplies of compressed air<br />

contain condensed water,<br />

oil, colour residues and rust<br />

particles from compressors.<br />

These impurities cause the abrasive<br />

material to get lumpy,<br />

clog the fine tubes of compressed<br />

air units and, when<br />

blasted out, contaminate the<br />

surface of the workpieces.<br />

With compressed air units<br />

(sandblasters, devesting<br />

chisels, turbines, vacuum<br />

pressure casting machines<br />

etc.) this often leads to malfunctions,<br />

increased servicing<br />

and maintenance costs,<br />

downtime and a reduced<br />

service life of the unit.<br />

• Three-step filter system:<br />

A) prefilter: grit particles up<br />

to 40 μm.<br />

B) fine filter: ultra-fine<br />

particles and water droplets<br />

up to 0.01 μm.<br />

C) fine filter with viewing<br />

glass and integrated fully<br />

automatic outlet at max.<br />

filling level.<br />

D) active carbon filter:<br />

oil up to a residual content<br />

of 0.003 ppm (mg/m 3 ).<br />

• filters water, oil and dirt<br />

particles with absolute<br />

reliability.<br />

• all filters can be exchanged<br />

easily without disassembling<br />

the entire unit.<br />

• active carbon filter change<br />

indicated by discoloration<br />

under the transparent cover.<br />

• up to three sandblasters can<br />

be connected to one filter.<br />

• assembly close to the sandblasters.<br />

Advantages:<br />

• less downtime with compressed<br />

air units.<br />

• increased service life.<br />

• reduced servicing and maintenance<br />

costs.<br />

Description Art. No.<br />

Compressed air filter 2940-0000<br />

incl. connection set<br />

and filter inserts<br />

C<br />

Technical details<br />

Supply pressure<br />

max. 10 bar, 145 psi<br />

Air quality ISO 8573-1, Class 1.7.1<br />

Flow rate<br />

420 l/min (at 6.3 bar)<br />

Dimensions<br />

210 x 280 mm<br />

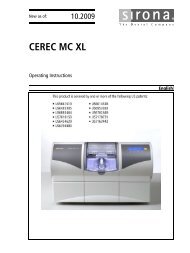

Optimum lighting for blasting chambers<br />

basic lighting<br />

upgrade set<br />

Prior to 1998 the Basic units<br />

were delivered with a popin<br />

lamp. We then upgraded to<br />

an improved, builtin Basic light.<br />

For all pre-1998 units we now<br />

offer a do-it-yourself lighting<br />

upgrade set.<br />

• brighter and better illumination<br />

of the blasting<br />

chamber.<br />

• flicker-free light with<br />

2400 LUX.<br />

• conventional, economical<br />

fluorescent tube.<br />

• wear-resistant, protective<br />

blind strip.<br />

• simple to install following<br />

instructions.<br />

Conventional lighting (1400 LUX)<br />

New Basic lighting (2400 LUX)<br />

Description Art. No. Art. No.<br />

230/240 V 90–120 V<br />

Lighting upgrade set with accessories 92900-3230 92900-3110<br />

28