CHAPTER 27 ⢠Statistical Process Control

CHAPTER 27 ⢠Statistical Process Control

CHAPTER 27 ⢠Statistical Process Control

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>27</strong>-16 <strong>CHAPTER</strong> <strong>27</strong> • <strong>Statistical</strong> <strong>Process</strong> <strong>Control</strong><br />

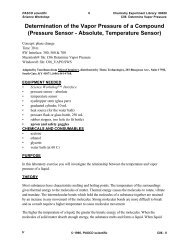

TABLE <strong>27</strong>.2 Three sets of x _ ’s from 20 samples of size 4<br />

SAMPLE DATA SET A DATA SET B DATA SET C<br />

1 11.602 11.6<strong>27</strong> 11.495<br />

2 11.547 11.613 11.475<br />

3 11.312 11.493 11.465<br />

4 11.449 11.602 11.497<br />

5 11.401 11.360 11.573<br />

6 11.608 11.374 11.563<br />

7 11.471 11.592 11.321<br />

8 11.453 11.458 11.533<br />

9 11.446 11.552 11.486<br />

10 11.522 11.463 11.502<br />

11 11.664 11.383 11.534<br />

12 11.823 11.715 11.624<br />

13 11.629 11.485 11.629<br />

14 11.602 11.509 11.575<br />

15 11.756 11.429 11.730<br />

16 11.707 11.477 11.680<br />

17 11.612 11.570 11.729<br />

18 11.628 11.623 11.704<br />

19 11.603 11.472 12.052<br />

20 11.816 11.531 11.905<br />

s CHARTS FOR PROCESS MONITORING<br />

The x charts in Figures <strong>27</strong>.4(b), <strong>27</strong>.5, and <strong>27</strong>.6 were easy to interpret because<br />

the process standard deviation remained fixed at 43 mV. The effects of moving<br />

the process mean away from its in-control value (<strong>27</strong>5 mV) are then clear to see.<br />

We know that even the simplest description of a distribution should give both a<br />

measure of center and a measure of spread. So it is with control charts. We must<br />

monitor both the process center, using an x chart, and the process spread, using a<br />

control chart for the sample standard deviation s.<br />

The standard deviation s does not have a Normal distribution, even approximately.<br />

Under the process-monitoring conditions, the sampling distribution<br />

of s is skewed to the right. Nonetheless, control charts for any statistic are<br />

based on the “plus or minus three standard deviations” idea motivated by<br />

the 68–95–99.7 rule for Normal distributions. <strong>Control</strong> charts are intended to<br />

be practical tools that are easy to use. Standard practice in process control<br />

therefore ignores such details as the effect of non-Normal sampling distributions.<br />

Here is the general control chart setup for a sample statistic Q (short for<br />

“quality characteristic”).