CHAPTER 27 ⢠Statistical Process Control

CHAPTER 27 ⢠Statistical Process Control

CHAPTER 27 ⢠Statistical Process Control

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>27</strong>-24 <strong>CHAPTER</strong> <strong>27</strong> • <strong>Statistical</strong> <strong>Process</strong> <strong>Control</strong><br />

x and R charts, remember that the interpretation of these charts is just like the<br />

interpretation of x and s charts.<br />

Additional out-of-control signals. So far, we have used only the basic “one<br />

point beyond the control limits” criterion to signal that a process may have gone<br />

out of control. We would like a quick signal when the process moves out of control,<br />

but we also want to avoid “false alarms,” signals that occur just by chance<br />

when the process is really in control. The standard 3 control limits are chosen to<br />

prevent too many false alarms, because an out-of-control signal calls for an effort<br />

to find and remove a special cause. As a result, x charts are often slow to<br />

respond to a gradual drift in the process center that continues for some time<br />

before finally forcing a reading outside the control limits. We can speed the<br />

response of a control chart to lack of control—at the cost of also enduring more<br />

false alarms—by adding patterns other than “one-point-out” as signals. The most<br />

common step in this direction is to add a runs signal to the x chart.<br />

OUT-OF-CONTROL SIGNALS<br />

x and s or x and R control charts produce an out-of-control signal if:<br />

■ One-point-out: A single point lies outside the 3 control limits of either chart.<br />

■ Run: The x chart shows 9 consecutive points above the center line or 9 consecutive<br />

points below the center line. The signal occurs when we see the 9th point of the run.<br />

EXAMPLE <strong>27</strong>.7 Using the runs signal<br />

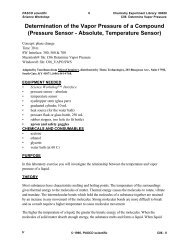

Figure <strong>27</strong>.11 reproduces the x chart from Figure <strong>27</strong>.6. The process center began a<br />

gradual upward drift at Sample 11. The chart shows the effect of the drift—the sample<br />

400<br />

x<br />

x<br />

350<br />

UCL<br />

x<br />

Sample mean<br />

300<br />

250<br />

x<br />

200<br />

LCL<br />

FIGURE <strong>27</strong>.11<br />

x chart for mesh tension data when<br />

the process center drifts upward. The<br />

“run of 9” signal gives an out-of-control<br />

warning at Sample 17.<br />

150<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20<br />

Sample number