CHAPTER 27 ⢠Statistical Process Control

CHAPTER 27 ⢠Statistical Process Control

CHAPTER 27 ⢠Statistical Process Control

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>27</strong>-6 <strong>CHAPTER</strong> <strong>27</strong> • <strong>Statistical</strong> <strong>Process</strong> <strong>Control</strong><br />

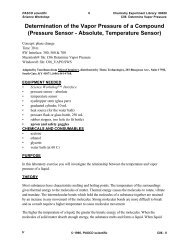

FIGURE <strong>27</strong>.2<br />

Flowchart of the hot-forging process<br />

in Example <strong>27</strong>.1. Use this as a model<br />

for flowcharts: decision points appear<br />

as diamonds, and other steps in the<br />

process appear as rectangles. Arrows<br />

represent flow from step to step.<br />

Receive the material<br />

Check for<br />

size and metallurgy<br />

O.K.<br />

No<br />

Scrap<br />

Yes<br />

Cut to the billet<br />

length<br />

Deburr<br />

Yes<br />

Check for<br />

size<br />

O.K.<br />

No<br />

Oversize<br />

No<br />

Scrap<br />

Yes<br />

Heat billet to the<br />

required temperature<br />

Forge to the size<br />

Flash trim<br />

and wash<br />

Shot blast<br />

Check for<br />

size and metallurgy<br />

O.K.<br />

Yes<br />

Bar code and store<br />

No<br />

Scrap<br />

data entry errors per week. The personnel department may measure the time to<br />

process employee insurance claims or the percent of job offers that are accepted.<br />

In the case of complex processes, it is wise to measure key steps within the<br />

process rather than just final outputs. The process team in Example <strong>27</strong>.1 might<br />

recommend that the temperature of the die and of the billet be measured just<br />

before forging.