CHAPTER 27 ⢠Statistical Process Control

CHAPTER 27 ⢠Statistical Process Control

CHAPTER 27 ⢠Statistical Process Control

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>27</strong>-30 <strong>CHAPTER</strong> <strong>27</strong> • <strong>Statistical</strong> <strong>Process</strong> <strong>Control</strong><br />

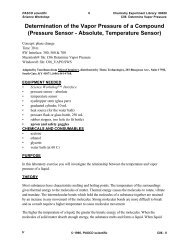

FIGURE <strong>27</strong>.13<br />

x chart based on past data for the viscosity<br />

data of Table <strong>27</strong>.5. The samples<br />

for Shifts 1 and 6 have been removed<br />

because s-type special causes active in<br />

those samples are no longer active.<br />

The x chart shows poor control.<br />

Sample mean<br />

54<br />

52<br />

50<br />

48<br />

46<br />

UCL x x<br />

LCL<br />

x<br />

x<br />

xx<br />

x<br />

44<br />

2 4 6 8 10 12 14 16 18 20 22 24<br />

Sample number<br />

variation is now stable, there is excessive variation from shift to shift. To find the<br />

cause, we must understand the details of the process, but knowing that the special<br />

cause or causes operate between shifts is a big help. If the reactor is set up anew<br />

at the beginning of each shift, that’s one place to look more closely.<br />

Step 4. Once the x and s charts are both in control (looking backward), use<br />

the estimates mˆ and ŝ from the points in control to set tentative control limits<br />

to monitor the process going forward. If it remains in control, we can update the<br />

charts and move to the process-monitoring stage.<br />

APPLY YOUR KNOWLEDGE<br />

<strong>27</strong>.20 From setup to monitoring. Suppose that when the chart setup project of<br />

Example <strong>27</strong>.8 is complete, the points remaining after removing special causes have<br />

x 48.7 and s 0.92. What are the center line and control limits for the x and s<br />

charts you would use to monitor the process going forward?<br />

<strong>27</strong>.21 Estimating process parameters. The x and s control charts for the meshtensioning<br />

example (Figures <strong>27</strong>.4(b) (page <strong>27</strong>-13) and <strong>27</strong>.7 (page <strong>27</strong>-19)) were<br />

based on <strong>27</strong>5 mV and 43 mV. Table <strong>27</strong>.1 (page <strong>27</strong>-12) gives the 20 most<br />

recent samples from this process.<br />

(a) Estimate the process and based on these 20 samples.<br />

(b) Your calculations suggest that the process may now be less than 43 mV.<br />

Explain why the s chart in Figure <strong>27</strong>.7 (page <strong>27</strong>-19) suggests the same conclusion.<br />

(If this pattern continues, we would eventually update the value of <br />

used for control limits.) MONITORS<br />

<strong>27</strong>.22 Hospital losses. Table <strong>27</strong>.6 gives data on the losses (in dollars) incurred by a<br />

hospital in treating major joint replacement (DRG 209) patients. 13 The hospital