Kalzip® Systems

Kalzip® Systems

Kalzip® Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Design specifications<br />

6.8 Thermal expansion<br />

Temperature changes can cause length<br />

variations and these must be taken into<br />

account. The thermal expansion coefficient<br />

of aluminium in the observed temperature<br />

range is approx 24 x 10–6/K. When the profiled<br />

sheets are installed at a given temperature<br />

of 20°C, there will be an expansion<br />

in sheet length of approx. 1.5 mm/m in<br />

summer (+ 80°C) and a contraction in sheet<br />

length of approx. 1 mm/m in winter (-20°C).<br />

However, as adjacent components are<br />

also subject to variations in temperature,<br />

and the substructure can usually absorb<br />

elongations, a variation in movement of<br />

± 0.5 mm/m may be applied to the sheet<br />

length in practice. If these requirements<br />

are not fulfilled then the maximum values<br />

stated above must be assumed.<br />

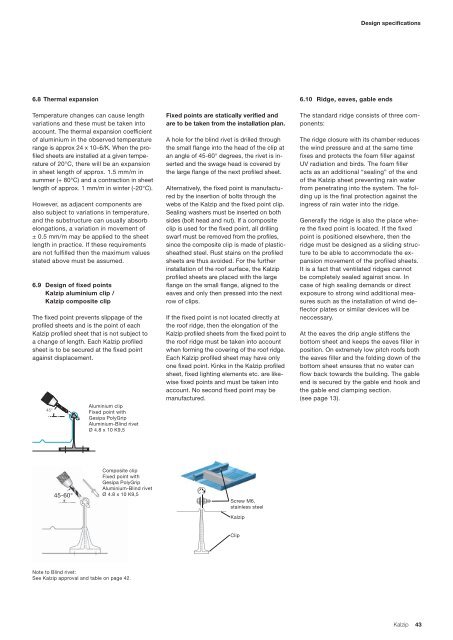

6.9 Design of fixed points<br />

Kalzip aluminium clip /<br />

Kalzip composite clip<br />

The fixed point prevents slippage of the<br />

profiled sheets and is the point of each<br />

Kalzip profiled sheet that is not subject to<br />

a change of length. Each Kalzip profiled<br />

sheet is to be secured at the fixed point<br />

against displacement.<br />

Aluminium clip<br />

Fixed point with<br />

Gesipa PolyGrip<br />

Aluminium-Blind rivet<br />

Ø 4.8 x 10 K9,5<br />

Fixed points are statically verified and<br />

are to be taken from the installation plan.<br />

A hole for the blind rivet is drilled through<br />

the small flange into the head of the clip at<br />

an angle of 45-60° degrees, the rivet is inserted<br />

and the swage head is covered by<br />

the large flange of the next profiled sheet.<br />

Alternatively, the fixed point is manufactured<br />

by the insertion of bolts through the<br />

webs of the Kalzip and the fixed point clip.<br />

Sealing washers must be inserted on both<br />

sides (bolt head and nut). If a composite<br />

clip is used for the fixed point, all drilling<br />

swarf must be removed from the profiles,<br />

since the composite clip is made of plasticsheathed<br />

steel. Rust stains on the profiled<br />

sheets are thus avoided. For the further<br />

installation of the roof surface, the Kalzip<br />

profiled sheets are placed with the large<br />

flange on the small flange, aligned to the<br />

eaves and only then pressed into the next<br />

row of clips.<br />

If the fixed point is not located directly at<br />

the roof ridge, then the elongation of the<br />

Kalzip profiled sheets from the fixed point to<br />

the roof ridge must be taken into account<br />

when forming the covering of the roof ridge.<br />

Each Kalzip profiled sheet may have only<br />

one fixed point. Kinks in the Kalzip profiled<br />

sheet, fixed lighting elements etc. are likewise<br />

fixed points and must be taken into<br />

account. No second fixed point may be<br />

manufactured.<br />

6.10 Ridge, eaves, gable ends<br />

The standard ridge consists of three components:<br />

The ridge closure with its chamber reduces<br />

the wind pressure and at the same time<br />

fixes and protects the foam filler against<br />

UV radiation and birds. The foam filler<br />

acts as an additional “sealing” of the end<br />

of the Kalzip sheet preventing rain water<br />

from pene trating into the system. The folding<br />

up is the final protection against the<br />

ingress of rain water into the ridge.<br />

Generally the ridge is also the place where<br />

the fixed point is located. If the fixed<br />

point is positioned elsewhere, then the<br />

ridge must be designed as a sliding structure<br />

to be able to accom modate the expansion<br />

movement of the profiled sheets.<br />

It is a fact that ventilated ridges cannot<br />

be completely sealed against snow. In<br />

case of high sealing demands or direct<br />

exposure to strong wind additional measures<br />

such as the installation of wind deflector<br />

plates or similar devices will be<br />

neccessary.<br />

At the eaves the drip angle stiffens the<br />

bottom sheet and keeps the eaves filler in<br />

position. On extremely low pitch roofs both<br />

the eaves filler and the folding down of the<br />

bottom sheet ensures that no water can<br />

flow back towards the building. The gable<br />

end is secured by the gable end hook and<br />

the gable end clamping section.<br />

(see page 13).<br />

45-60°<br />

Composite clip<br />

Fixed point with<br />

Gesipa PolyGrip<br />

Aluminium-Blind rivet<br />

Ø 4.8 x 10 K9,5<br />

Screw M6,<br />

stainless steel<br />

Kalzip<br />

Clip<br />

Note to Blind rivet:<br />

See Kalzip approval and table on page 42.<br />

Kalzip 43