Recycling of Low Grade Clothing Waste - Oakdene Hollins

Recycling of Low Grade Clothing Waste - Oakdene Hollins

Recycling of Low Grade Clothing Waste - Oakdene Hollins

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

© <strong>Oakdene</strong> <strong>Hollins</strong> Ltd, Salvation Army Trading Company Ltd<br />

Nonwovens Innovation & Research Institute Ltd September 2006<br />

composites market despite their dark brown appearance. Pigmentation <strong>of</strong> resins is<br />

relatively inexpensive and easy to administer but visually demanding applications<br />

use separate gel coat layers to create the final composite part colour.<br />

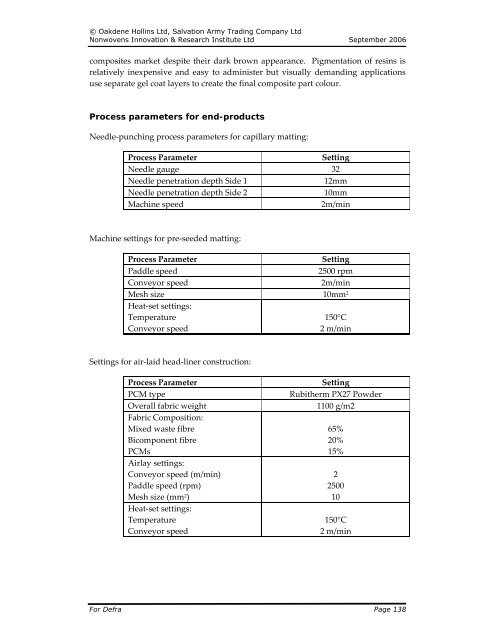

Process parameters for end-products<br />

Needle‐punching process parameters for capillary matting:<br />

Process Parameter<br />

Setting<br />

Needle gauge 32<br />

Needle penetration depth Side 1<br />

12mm<br />

Needle penetration depth Side 2<br />

10mm<br />

Machine speed<br />

2m/min<br />

Machine settings for pre‐seeded matting:<br />

Process Parameter<br />

Setting<br />

Paddle speed<br />

2500 rpm<br />

Conveyor speed<br />

2m/min<br />

Mesh size 10mm 2<br />

Heat‐set settings:<br />

Temperature<br />

Conveyor speed<br />

150°C<br />

2 m/min<br />

Settings for air‐laid head‐liner construction:<br />

Process Parameter<br />

PCM type<br />

Overall fabric weight<br />

Fabric Composition:<br />

Mixed waste fibre<br />

Bicomponent fibre<br />

PCMs<br />

Airlay settings:<br />

Conveyor speed (m/min)<br />

Paddle speed (rpm)<br />

Mesh size (mm 2 )<br />

Heat‐set settings:<br />

Temperature<br />

Conveyor speed<br />

Setting<br />

Rubitherm PX27 Powder<br />

1100 g/m2<br />

65%<br />

20%<br />

15%<br />

2<br />

2500<br />

10<br />

150°C<br />

2 m/min<br />

For Defra Page 138