Recycling of Low Grade Clothing Waste - Oakdene Hollins

Recycling of Low Grade Clothing Waste - Oakdene Hollins

Recycling of Low Grade Clothing Waste - Oakdene Hollins

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

© <strong>Oakdene</strong> <strong>Hollins</strong> Ltd, Salvation Army Trading Company Ltd<br />

Nonwovens Innovation & Research Institute Ltd September 2006<br />

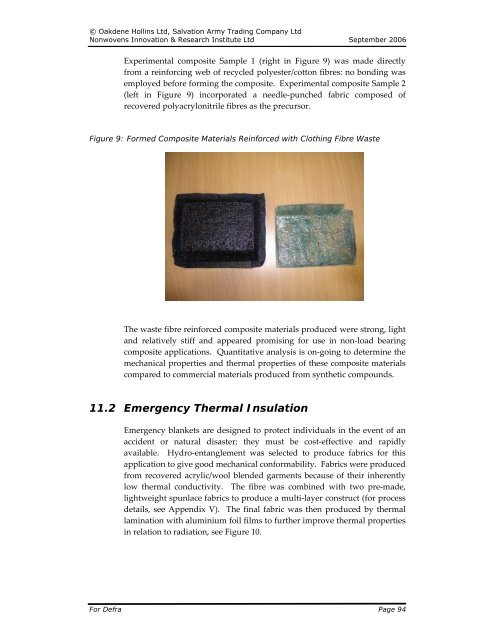

Experimental composite Sample 1 (right in Figure 9) was made directly<br />

from a reinforcing web <strong>of</strong> recycled polyester/cotton fibres: no bonding was<br />

employed before forming the composite. Experimental composite Sample 2<br />

(left in Figure 9) incorporated a needle‐punched fabric composed <strong>of</strong><br />

recovered polyacrylonitrile fibres as the precursor.<br />

Figure 9: Formed Composite Materials Reinforced with <strong>Clothing</strong> Fibre <strong>Waste</strong><br />

The waste fibre reinforced composite materials produced were strong, light<br />

and relatively stiff and appeared promising for use in non‐load bearing<br />

composite applications. Quantitative analysis is on‐going to determine the<br />

mechanical properties and thermal properties <strong>of</strong> these composite materials<br />

compared to commercial materials produced from synthetic compounds.<br />

11.2 Emergency Thermal Insulation<br />

Emergency blankets are designed to protect individuals in the event <strong>of</strong> an<br />

accident or natural disaster; they must be cost‐effective and rapidly<br />

available. Hydro‐entanglement was selected to produce fabrics for this<br />

application to give good mechanical conformability. Fabrics were produced<br />

from recovered acrylic/wool blended garments because <strong>of</strong> their inherently<br />

low thermal conductivity. The fibre was combined with two pre‐made,<br />

lightweight spunlace fabrics to produce a multi‐layer construct (for process<br />

details, see Appendix V). The final fabric was then produced by thermal<br />

lamination with aluminium foil films to further improve thermal properties<br />

in relation to radiation, see Figure 10.<br />

For Defra Page 94