SMT/THR PCB-COMPONENTS

SMT/THR PCB-COMPONENTS

SMT/THR PCB-COMPONENTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

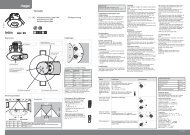

Various requirements for the leaded<br />

components can now be derived from<br />

these parameters:<br />

• as the housing of the leaded<br />

component must not touch the solder<br />

paste, its stand-off height should be<br />

at least 0.3 mm<br />

• the pin cross-section geometry, the<br />

pin tip and its length must be<br />

optimised to minimise the paste<br />

volume needed<br />

If the degree of solder paste filling is too<br />

low, then it is advisable to overprint to<br />

achieve the necessary paste volume.<br />

Overprinting means that the stencil hole<br />

diameter is designed to be larger than<br />

the soldering eyelet diameter and the<br />

paste is printed over an area larger than<br />

the soldering eyelet, and out onto the<br />

<strong>PCB</strong>. This can, of course, cause soiling<br />

of the underside of the stencil, which<br />

can be removed by a shorter cleaning<br />

cycle of the stencil.<br />

Overprinting can lead to soiling of the underside of the stencil<br />

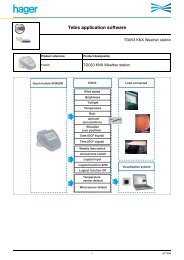

Solutions and recommendations from Weidmüller<br />

To realise the lowest possible paste volume in stencil printing, the SL-<strong>SMT</strong> pin<br />

headers from Weidmüller feature short octagonal pins with chamfered pin ends.<br />

Above all thanks to the pin length of only 1.5 mm for standard pc boards with a<br />

thickness of 1.6 mm, a filling degree of 90 % only is adequate for an optimal solder<br />

joint shape. Therefore in most cases normal single-layer stencils for fine-pitch<br />

technology and the standard process parameters for the squeegee speed and<br />

pressure can be used during paste printing.<br />

Further advantage: in the placement process, the paste is forced out of the<br />

placement hole to a lesser extent.<br />

APPLICATION INFORMATION 11