SMT/THR PCB-COMPONENTS

SMT/THR PCB-COMPONENTS

SMT/THR PCB-COMPONENTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

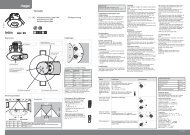

3 THE <strong>SMT</strong> PROCESS<br />

FOR MODULES WITH <strong>THR</strong> <strong>COMPONENTS</strong><br />

3.4 The placement process<br />

Automatic sequential placement is one of<br />

the placement processes that is used<br />

most frequently in the <strong>SMT</strong> process. Use<br />

is made of both pick & place systems<br />

and of collect & place systems (chip<br />

shooter). In the pick & place station, only<br />

one components is taken from the<br />

component feeder by means of a vacuum<br />

pipette, and is placed on the pcb.<br />

Pick & Place head transports SL-<strong>SMT</strong> 3.5<br />

By contrast, a chip shooter transports<br />

several components to the corresponding<br />

placement position and deposits them<br />

there.<br />

Packaging of the components is the<br />

basis for the use of both processes.<br />

A distinction is made between tape-onreel,<br />

tray, tube and bulk. The pick & place<br />

process with tape-on-reel or tray has<br />

established itself for leaded terminal<br />

elements.<br />

The following parameters must be<br />

observed with regard to the optimum<br />

placement suitability of leaded terminal<br />

elements and thus easy integration<br />

into the placement process with usual<br />

standard placement systems:<br />

Tray packaging accord. to IEC 286-5<br />

• packaging in line with standards:<br />

fully automatic feeding of the<br />

terminal elements with tape-on-reel<br />

or tray is possible<br />

• dimensional stability of the<br />

component: lowest possible water<br />

absorption during storage under<br />

normal climatic conditions ensuring<br />

pitch fidelity of the component<br />

• suction surface of the component:<br />

determined in relation to the weight<br />

or size for the use of standardised<br />

vacuum nozzles<br />

• precision of the pin end position:<br />

smallest possible tolerances<br />

(in addition to hole position and<br />

machine placement tolerance)<br />

prevent problems caused by collision<br />

of the component with the <strong>PCB</strong><br />

This results in the following<br />

requirements for leaded terminal<br />

elements:<br />

• minimised weight for an placement<br />

speed that is as high as possible<br />

• minimised component length for a<br />

high rotation and transport speed<br />

and thus maximum placement<br />

performance<br />

• minimised height to avoid a<br />

restriction of the travel height<br />

over the <strong>PCB</strong> and thus to prevent<br />

collisions<br />

Tape-on-reel packaging accord. to IEC 286-3<br />

• minimised tooling effort by using<br />

components in high packed numbers<br />

to achieve lower product and tooling<br />

costs<br />

12 APPLICATION INFORMATION