Areva EPR

Areva EPR

Areva EPR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

■ <strong>EPR</strong> NUCLEAR ISLAND<br />

Instrumentation (level 0)<br />

A number of instrumentation channels supply measured data for<br />

control, surveillance and protection systems and for information of the<br />

control room staff. Multiple-channel acquisition is used for important<br />

controls such as control of pressure and temperature of the primary<br />

coolant, liquid level in the reactor pressure vessel. Multiple-channel<br />

and diversified data acquisition means are implemented.<br />

Aeroball system<br />

Carrier gas<br />

Concerning the protection of the reactor, a major aspect is the<br />

capacity to predict and measure the nuclear power (or neutron flux)<br />

level and the three dimensional distribution of power in the core.<br />

Ball guide tube<br />

The measurement of the power level is performed using ex-core<br />

instrumentation which also provides signals to monitor the core<br />

criticality. Relying on temperature measurements in the cold and hot<br />

legs of the four primary loops, a quadruple-redundant primary heat<br />

balance is achieved and complemented by neutron flux measurements<br />

with very short response time.<br />

Prediction and measurement of the three-dimensional power<br />

distribution relies on two types of in-core instrumentation:<br />

• “movable” reference instrumentation to validate the core design<br />

and to calibrate the other sensors utilized for core surveillance and<br />

protection purposes,<br />

• “fixed” instrumentation to deliver online information to the<br />

surveillance and protection systems which actuate appropriate<br />

actions and countermeasures in case of anomalies or exceeding<br />

of predefined limits.<br />

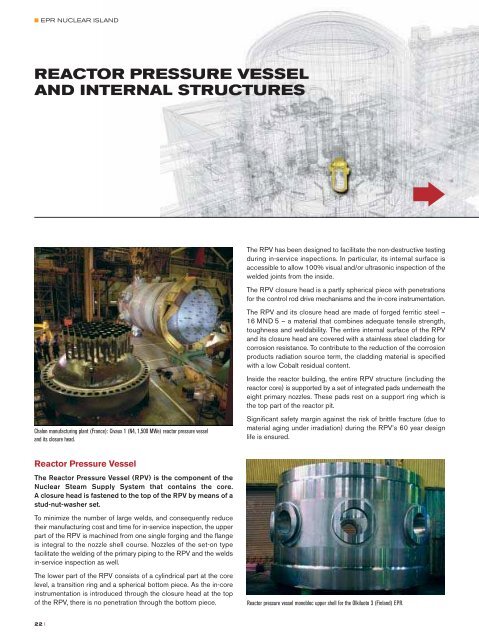

The movable reference instrumentation for power distribution<br />

assessment is an “aeroball” system. Stacks of vanadium-alloy balls,<br />

inserted from the top of the pressure vessel, are pneumatically<br />

transported into the reactor core (inside guide thimbles of fuel<br />

assemblies), then, after three minutes in the core, to a bench where the<br />

activation of each probe is measured at 30 positions in five minutes.<br />

This gives values of the local neutron flux in the core, which are<br />

processed to construct the three-dimensional power distribution map.<br />

The fixed in-core instrumentation consists of neutron detectors<br />

and thermocouples to measure the neutron flux radial and axial<br />

distribution in the core and temperature radial distribution at the core<br />

outlet. The neutron flux signals are utilized to control the axial power<br />

distribution, and for core surveillance and protection. The core outlet<br />

thermocouples continuously measure the fuel assembly outlet<br />

temperature and provide signals for core monitoring in case of loss<br />

of coolant event. They also provide information on radial power<br />

distribution and thermal-hydraulic local conditions.<br />

A<br />

Shroud<br />

Steel balls<br />

Ball stop<br />

Active core height<br />

<strong>EPR</strong> in-core instrumentation<br />

B C D E F G H J K L M N P R S T<br />

17<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

241 Fuel assemblies<br />

89 Control rods<br />

12 In-core detectors<br />

40 Aeroball probes<br />

12 Instrumentation<br />

lance yokes<br />

42 I