SPRING 2012

Distributor's Link Magazine Spring Issue 2012 / VOL 35 / NO.2

Distributor's Link Magazine Spring Issue 2012 / VOL 35 / NO.2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

66 THE DISTRIBUTOR’S LINK<br />

BOLT MATERIAL STANDARDS REFER TO<br />

SEVERAL DIFFERENT TYPES OF STRENGTH<br />

by Joe Greenslade Director of Engineering Technology, IFI<br />

Most of the bolt material standards refer to five or<br />

six different strength values which sometimes causes<br />

confusion for those using the standards. To explain<br />

these different values I am going to use SAE J429, which<br />

can be found in Tables 1 and 5 on pages 164 and 171,<br />

respectively, in the IFI 8th Edition Inch Standards Book.<br />

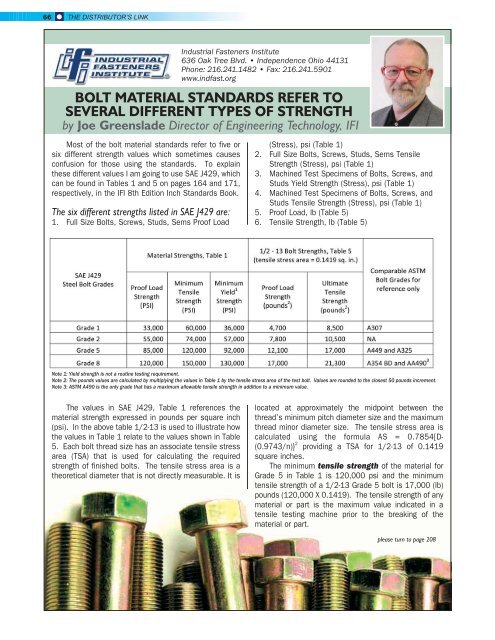

The six different strengths listed in SAE J429 are:<br />

1. Full Size Bolts, Screws, Studs, Sems Proof Load<br />

Industrial Fasteners Institute<br />

636 Oak Tree Blvd. • Independence Ohio 44131<br />

Phone: 216.241.1482 • Fax: 216.241.5901<br />

www.indfast.org<br />

(Stress), psi (Table 1)<br />

2. Full Size Bolts, Screws, Studs, Sems Tensile<br />

Strength (Stress), psi (Table 1)<br />

3. Machined Test Specimens of Bolts, Screws, and<br />

Studs Yield Strength (Stress), psi (Table 1)<br />

4. Machined Test Specimens of Bolts, Screws, and<br />

Studs Tensile Strength (Stress), psi (Table 1)<br />

5. Proof Load, lb (Table 5)<br />

6. Tensile Strength, lb (Table 5)<br />

Note 1: Yield strength is not a routine testing requirement.<br />

Note 2: The pounds values are calculated by multiplying the values in Table 1 by the tensile stress area of the test bolt. Values are rounded to the closest 50 pounds increment.<br />

Note 3: ASTM A490 is the only grade that has a maximum allowable tensile strength in addition to a minimum value.<br />

The values in SAE J429, Table 1 references the<br />

material strength expressed in pounds per square inch<br />

(psi). In the above table 1/2-13 is used to illustrate how<br />

the values in Table 1 relate to the values shown in Table<br />

5. Each bolt thread size has an associate tensile stress<br />

area (TSA) that is used for calculating the required<br />

strength of finished bolts. The tensile stress area is a<br />

theoretical diameter that is not directly measurable. It is<br />

located at approximately the midpoint between the<br />

thread’s minimum pitch diameter size and the maximum<br />

thread minor diameter size. The tensile stress area is<br />

calculated using the formula AS = 0.7854[D-<br />

(0.9743/n)} 2 providing a TSA for 1/2-13 of 0.1419<br />

square inches.<br />

The minimum tensile strength of the material for<br />

Grade 5 in Table 1 is 120,000 psi and the minimum<br />

tensile strength of a 1/2-13 Grade 5 bolt is 17,000 (lb)<br />

pounds (120,000 X 0.1419). The tensile strength of any<br />

material or part is the maximum value indicated in a<br />

tensile testing machine prior to the breaking of the<br />

material or part.<br />

please turn to page 208