SPRING 2012

Distributor's Link Magazine Spring Issue 2012 / VOL 35 / NO.2

Distributor's Link Magazine Spring Issue 2012 / VOL 35 / NO.2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

74 THE DISTRIBUTOR’S LINK<br />

Anthony Di Maio<br />

Anthony E. Di Maio attended Wentworth Institute and Northeastern University. In 1962 he<br />

started working with Blind Fasteners as Vice-President of Engineering & Manufacturing for two<br />

blind rivet manufacturers. He has been Chairman of the Technical Committee of the Industrial<br />

Fasteners Institute (IFI) and is still involved in the writing of IFI specifications. In 1991, he<br />

started ADM Engineering and is working with Fastener Manufacturers developing new<br />

fasteners and special machinery. He can be reached at ADM Engineering, 6 Hermon Ave.,<br />

Haverhill, MA 01832; phone and fax 978-521-0277; e-mail: tdimaio@verizon.net.<br />

CONSIDERATIONS WHEN SELECTING BLIND RIVETS<br />

The following considerations should be taken when<br />

selecting a blind rivet for your application.<br />

Tensile and Shear Values<br />

The blind rivet should have the proper tensile and<br />

shear strength to withstand all the forces your<br />

application could apply to the riveted joint. This force<br />

calculation should be made at the most extreme force<br />

condition on the riveted joint. This extreme tensile and<br />

shear force that is exerted on the blind rivet must be<br />

used for a secure riveted joint. All blind rivet<br />

manufacturer's list the tensile and shear values of all<br />

the diameters and alloys of the blind rivets they produce.<br />

Just by viewing the manufacturers catalog or the<br />

Industrial Fasteners Institute (IFI) blind rivet<br />

specifications, you can select the proper blind rivet that<br />

will satisfy your application.<br />

When calculating the correct tensile and shear<br />

values of the blind rivet for your application, a safety<br />

factor should be considered in your calculation. For<br />

example, if your components to be riveted will exert 500<br />

pounds of tensile and shear force to the blind rivet, you<br />

should add your safety factor percentage to the 500<br />

pounds. If your safety is 100% then you will select the<br />

rivet or rivets that can resist 1000 pounds tensile or<br />

shear force.<br />

Alloy<br />

The alloy of the blind rivet is the next consideration<br />

to be made. The alloy selection is determined by the<br />

tensile and shear values needed and also the<br />

environment that the blind rivet application will be<br />

subjected to. If your application is in contact with food,<br />

a stainless steel rivet body should be selected. This is<br />

a blind rivet with a stainless steel rivet body and a<br />

stainless steel mandrel. If your rivet application is<br />

outdoors and subjected to the weather, your alloy<br />

selection can be all stainless steel or all aluminum blind<br />

rivets. The tensile and shear calculation will determine<br />

which alloy should be used. Stainless steel has a higher<br />

tensile and shear value. There are blind rivets that have<br />

a combination of alloys. For example, aluminum rivet<br />

body with a steel mandrel. This blind rivet has a rivet<br />

body made of 5056 aluminum, which is stronger that<br />

5050 and 5052 aluminum rivet bodies. 5050 and 5952<br />

rivet bodies are used with aluminum mandrels. The<br />

5056 aluminum rivet body with a steel mandrel are used<br />

in applications that require higher tensile and shear<br />

values greater than the 5050 or 5052 aluminum rivet<br />

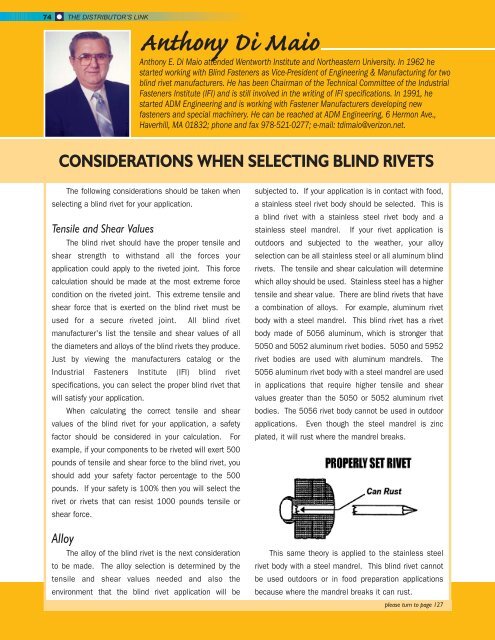

bodies. The 5056 rivet body cannot be used in outdoor<br />

applications. Even though the steel mandrel is zinc<br />

plated, it will rust where the mandrel breaks.<br />

This same theory is applied to the stainless steel<br />

rivet body with a steel mandrel. This blind rivet cannot<br />

be used outdoors or in food preparation applications<br />

because where the mandrel breaks it can rust.<br />

please turn to page 127