milling of t-slots - Horn USA, Inc.

milling of t-slots - Horn USA, Inc.

milling of t-slots - Horn USA, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

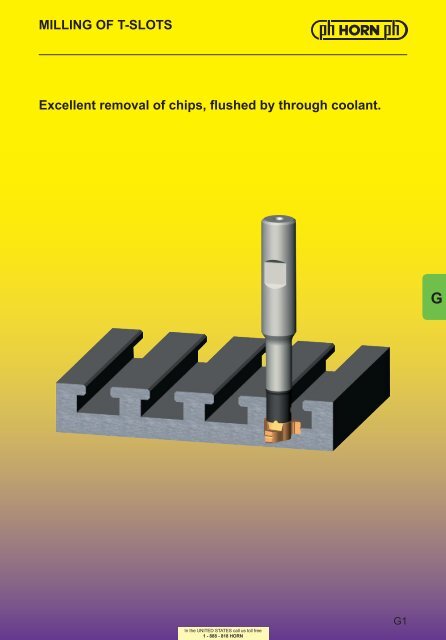

MILLING OF T-SLOTS<br />

Excellent removal <strong>of</strong> chips, flushed by through coolant.<br />

G<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

G1

MILLING OF T-SLOTS<br />

MILLING SHANK Type<br />

MU311<br />

Cutting edge Ø Ds .669″<br />

Material <strong>of</strong> shank: Carbide - Giving a good vibration resistance<br />

for use with Insert<br />

Type<br />

311<br />

G<br />

Picture = right hand cutting version shown<br />

Part number Ds l 1<br />

l 2<br />

d 1<br />

d<br />

MU311.0625.00B .669 3.543 .984 .354 .625<br />

Further sizes upon request<br />

Ordering note:<br />

Milling cutter shanks with damaged seating can be repaired by HORN.<br />

Dimensions in inch<br />

Spare parts<br />

Milling shank Screw Torque TORX PLUS® Wrench<br />

MU311.0625.00B 4.16T15KP 35 - 40 lbf-in. T15PQ<br />

G2<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

MILLING OF T-SLOTS<br />

MILLING SHANK Type<br />

M311<br />

Cutting edge Ø<br />

Ds .669″ (17.0 mm)<br />

Material <strong>of</strong> shank: Carbide - Giving a good vibration resistance<br />

for use with Insert<br />

Type<br />

311<br />

Picture = right hand cutting version shown<br />

G<br />

Part number Ds l 1<br />

l 2<br />

d 1<br />

d<br />

M311.0016.00B 17 90 25 9 16<br />

M311.0016.00E 17 90 25 9 16<br />

Further sizes upon request<br />

Ordering note:<br />

Milling cutter shanks with damaged seating can be repaired by HORN.<br />

Dimensions in mm<br />

Spare parts<br />

Milling shank Screw Torque TORX PLUS® Wrench<br />

M311.0016.00... 4.16T15KP 35 - 40 lbf-in. T15PQ<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

G3

MILLING OF T-SLOTS<br />

INSERT Type<br />

311<br />

T-Slots DIN 650<br />

Cutting edge Ø<br />

a .394″<br />

Ds .669″<br />

for use with Milling shank<br />

Type<br />

M311<br />

G<br />

Picture = right hand cutting version shown<br />

Part number Ds w s r 1<br />

r 2<br />

a<br />

MG12<br />

TI25<br />

TF45<br />

311.1016.00 .669 .283 .303 .020 .031 .394 •<br />

Dimensions in inch<br />

●/+ = on stock / 6 weeks<br />

Further sizes upon request<br />

G4<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

CHAMFERING OF T-SLOTS<br />

INSERT Type<br />

311<br />

T-Slots DIN 650<br />

Cutting edge Ø<br />

a .394/.472/.551″<br />

Ds .622″<br />

for use with Milling shank<br />

Type<br />

M311<br />

Picture = right hand cutting version shown<br />

G<br />

Part number s E Ds<br />

MG12<br />

TN35<br />

TI25<br />

TF45<br />

311.4216.00 .230 .118 .622 •<br />

Dimensions in inch<br />

●/+ = on stock / 6 weeks<br />

Further sizes upon request<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

G5

MILLING OF T-SLOTS<br />

MILLING SHANK Type<br />

MU313<br />

Cutting edge Ø Ds .787″<br />

Material <strong>of</strong> shank: Carbide - Giving a good vibration resistance<br />

for use with Insert<br />

Type<br />

313<br />

G<br />

Picture = right hand cutting version shown<br />

Part number Ds l 1<br />

l 2<br />

d 1<br />

d<br />

MU313.0625.00B .787 3.661 1.181 .453 .625<br />

Further sizes upon request<br />

Ordering note:<br />

Milling cutter shanks with damaged seating can be repaired by HORN.<br />

Dimensions in inch<br />

Spare parts<br />

Milling shank Screw Torque TORX PLUS® Wrench<br />

MU313.0625.00B 5.13T20KP 53 - 58 lbf-in. T20PQ<br />

G6<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

MILLING OF T-SLOTS<br />

MILLING SHANK Type<br />

M313<br />

Cutting edge Ø<br />

Ds .787″ (20.0 mm)<br />

Material <strong>of</strong> shank: Carbide - Giving a good vibration resistance<br />

for use with Insert<br />

Type<br />

313<br />

Picture = right hand cutting version shown<br />

G<br />

Part number Ds l 1<br />

l 2<br />

d 1<br />

d<br />

M313.0016.00B 20 93 30 11.5 16<br />

M313.0016.00E 20 93 30 11.5 16<br />

Further sizes upon request<br />

Ordering note:<br />

Milling cutter shanks with damaged seating can be repaired by HORN.<br />

Dimensions in mm<br />

Spare parts<br />

Milling shank Screw Torque TORX PLUS® Wrench<br />

M313.0016.00... 5.13T20KP 53 - 58 lbf-in. T20PQ<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

G7

MILLING OF T-SLOTS<br />

INSERT Type<br />

313<br />

T-Slots DIN 650<br />

Cutting edge Ø<br />

a .472″<br />

Ds .787″<br />

for use with Milling shank<br />

Type<br />

M313<br />

G<br />

Picture = right hand cutting version shown<br />

Part number Ds w s r 1<br />

r 2<br />

a<br />

MG12<br />

TI25<br />

TF45<br />

313.1219.00 .787 .323 .343 .020 .031 .472 •<br />

Dimensions in inch<br />

●/+ = on stock / 6 weeks<br />

Further sizes upon request<br />

G8<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

MILLING OF T-SLOTS<br />

MILLING SHANK Type<br />

MU328<br />

Cutting edge Ø Ds .945″<br />

Material <strong>of</strong> shank: Carbide - Giving a good vibration resistance<br />

for use with Insert<br />

Type<br />

328<br />

Picture = right hand cutting version shown<br />

G<br />

Part number Ds l 1<br />

l 2<br />

d 1<br />

d<br />

MU328.0750.00B .945 4.094 1.378 .531 .750<br />

Further sizes upon request<br />

Ordering note:<br />

Milling cutter shanks with damaged seating can be repaired by HORN.<br />

Dimensions in inch<br />

Spare parts<br />

Milling shank Screw Torque TORX PLUS® Wrench<br />

MU328.0750.00B 5.13T20KP 53 - 58 lbf-in. T20PQ<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

G9

MILLING OF T-SLOTS<br />

MILLING SHANK Type<br />

M328<br />

Cutting edge Ø<br />

Ds .945″ (24.0 mm)<br />

Material <strong>of</strong> shank: Carbide - Giving a good vibration resistance<br />

for use with Insert<br />

Type<br />

328<br />

G<br />

Picture = right hand cutting version shown<br />

Part number Ds l 1<br />

l 2<br />

d 1<br />

d<br />

M328.0020.00B 24 104 35 13.5 20<br />

M328.0020.00E 24 104 35 13.5 20<br />

Further sizes upon request<br />

Ordering note:<br />

Milling cutter shanks with damaged seating can be repaired by HORN.<br />

Dimensions in mm<br />

Spare parts<br />

Milling shank Screw Torque TORX PLUS® Wrench<br />

M328.0020.00... 5.13T20KP 53 - 58 lbf-in. T20PQ<br />

G10<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

MILLING OF T-SLOTS<br />

INSERT Type<br />

328<br />

T-Slots DIN 650<br />

Cutting edge Ø<br />

a .551″<br />

Ds .945″<br />

for use with Milling shank<br />

Type<br />

M328<br />

Picture = right hand cutting version shown<br />

G<br />

Part number Ds w s r 1<br />

r 2<br />

a<br />

MG12<br />

TI25<br />

TF45<br />

328.1423.00 .945 .362 .386 .020 .039 .551 •<br />

Dimensions in inch<br />

●/+ = on stock / 6 weeks<br />

Further sizes upon request<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

G11

MILLING OF T-SLOTS<br />

Application Technology<br />

a 2<br />

≈ 0.2 x s<br />

very recommandable<br />

not recommandable<br />

CUTTING DATA<br />

MILLING OF T-SLOTS<br />

G<br />

Workpiece material Cutting material v c<br />

[sfm] f z<br />

= IPT<br />

Ds .669"<br />

f z<br />

= IPT<br />

Ds .787"-.945"<br />

Carbon steel TI25 650 - 980 .0012 - .0025 .0020 - .0031<br />

Alloyed steel TI25 460 - 720 .0008 - .0016 .0012 - .0020<br />

Cast iron TI25 330 - 520 .0012 - .0025 .0020 - .0039<br />

CUTTING DATA<br />

CHAMFERING OF T-SLOTS<br />

Workpiece material Cutting material v c<br />

[sfm] f z<br />

= IPT<br />

Carbon steel TI25 980 - 1300 .0051 - .0083<br />

Alloyed steel TI25 590 - 980 .0039 - .0051<br />

Cast iron TI25 460 - 790 .0063 - .0106<br />

The cutting data are only valid for our available antivibration standard carbide toolholders (shanks).<br />

G12<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

TECHNICAL INFORMATION<br />

Feed rates and time calculation<br />

It is simple and easy to calculate your speed and feeds<br />

using HORN‘S HCT program. We recommend that<br />

you calculate the cutting data with this program as it<br />

will provide you with the best cutting performance and<br />

results. Basic features <strong>of</strong> the calculations can be found<br />

on the follwing pages.<br />

HCT<br />

(HORN Circular Technology)<br />

- safe and fast -<br />

Your cutting data for groove <strong>milling</strong> by<br />

circular interpolation <strong>of</strong> internal and<br />

external grooves as well as groove<br />

<strong>milling</strong> <strong>of</strong> linear grooves.<br />

System requirements from Windows 95.<br />

Available on CD-ROM.<br />

BASIC RECOMMENDATIONS<br />

Overhang <strong>of</strong> the <strong>milling</strong> cutter<br />

Select the shortest possible clamping device and <strong>milling</strong><br />

shank, and control the runout tolerance <strong>of</strong> the tools.<br />

Large cutting widths in combination with long overhangs<br />

require specific manufacturing methods such as dividing<br />

the cutting width to achieve the best possible cutting<br />

result due to reduced cutting forces.<br />

H<br />

Diameter <strong>of</strong> the <strong>milling</strong> cutter<br />

When using a large diameter cutter, whose relationship<br />

is close to the bore diameter, manufacturing cycletime<br />

can be reduced, due to the smaller center <strong>of</strong> rotation and<br />

higher feed rates. Many times the rotation <strong>of</strong> the <strong>milling</strong><br />

cutter centre will be defined by the parameters <strong>of</strong> the<br />

workpiece and the whole application setup.<br />

Clamping torque <strong>of</strong> the screws<br />

We recommend to use a torque screw driver to achieve<br />

the indicated torque values per insert and tool type.<br />

Additional additives such as copper paste are not<br />

permitted. This will have a negative effect and change<br />

the clamping forces.<br />

All clamping screws are already coated with<br />

additives.<br />

M d<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

H1

TECHNICAL INFORMATION<br />

Milling direction<br />

Most HORN <strong>milling</strong> tools are right handed , and it is<br />

recommended to use them with the climb <strong>milling</strong> process<br />

as this is generally recommend for carbide tools.<br />

H<br />

Milling entry into the workpiece<br />

A simple radial entry <strong>of</strong> the <strong>milling</strong> cutter creates a very<br />

long contact angle which leads to vibrations which will<br />

not disappear for the rest <strong>of</strong> the <strong>milling</strong> operation and are<br />

visual on the bottom <strong>of</strong> the groove.<br />

It is recommended to enter the groove with a ramp<br />

angle <strong>of</strong> 45° up to 180° to the maximum depth <strong>of</strong> cut.<br />

The calculated cutting data refers to the <strong>milling</strong> condition<br />

when the insert is in the full cut but can be also used for<br />

the entry loop.<br />

Ramp angle > 45°<br />

Bore <strong>milling</strong> and <strong>of</strong>fset <strong>milling</strong> by helical<br />

interpolation<br />

HORN <strong>milling</strong> inserts are manufactured with a round chip<br />

breaker. This means that beyond a depth <strong>of</strong> cut <strong>of</strong> 2 mm<br />

in axial direction the insert gets a negative cutting angle.<br />

Milling inserts are limited to a depth <strong>of</strong> cut <strong>of</strong> 2 mm when<br />

used for helical interpolation. Larger depths <strong>of</strong> cut can<br />

only be produced when choosing special chip breakers.<br />

Please contact us in case <strong>of</strong> any further questions.<br />

H2<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

TECHNICAL INFORMATION<br />

Sinlge edged inserts<br />

When entering through a bore <strong>of</strong>f center and without<br />

rotating it is possible to generate back chamfers and<br />

flats with inserts having a larger cutting diameter than<br />

the bore diameter. Single edged cutters have no run out<br />

tolerance.<br />

Thread <strong>milling</strong><br />

H<br />

With HORN thread <strong>milling</strong> inserts the thread pr<strong>of</strong>ile is<br />

generated in one full cut to the pr<strong>of</strong>ile depth <strong>of</strong> the thread.<br />

This produces threads with minimal taper especially in<br />

high alloyed steels.<br />

In blind holes it is recommended to mill from the bottom<br />

to the top. Otherwise there is the risk <strong>of</strong> damaging the<br />

tool because <strong>of</strong> <strong>milling</strong> into chips at the bottom <strong>of</strong> the<br />

blind hole.<br />

A general recommendation for thread <strong>milling</strong>:<br />

The <strong>milling</strong> cutter diameter should not exceed 70% <strong>of</strong> the<br />

minor diameter <strong>of</strong> the thread. Otherwise recutting <strong>of</strong> the<br />

pr<strong>of</strong>ile occurs which could bring the whole thread out <strong>of</strong><br />

tolerance.<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

H3

CHOICE OF CARBIDE GRADES<br />

Synthetic cutting-tool material<br />

PD10<br />

PD20<br />

Wear resistance<br />

Cutting speed<br />

Toughness<br />

Feed rate<br />

CB10<br />

CB20<br />

H<br />

Carbide Grades<br />

uncoated coated<br />

MG12 TI25<br />

MG12 TN35 TH35<br />

01<br />

10<br />

20<br />

30<br />

40<br />

10<br />

20<br />

30<br />

N<br />

40<br />

01<br />

10<br />

20<br />

30<br />

Non ferrous metal High temp. alloys Hardened materials<br />

S<br />

H<br />

Wear resistance<br />

Cutting speed<br />

Toughness<br />

Feed rate<br />

01<br />

10<br />

20<br />

30<br />

40<br />

10<br />

20<br />

30<br />

40<br />

01<br />

10<br />

20<br />

30<br />

P<br />

Carbide Grades<br />

Main selection supplementary grades<br />

H35<br />

TH35<br />

TN35<br />

TI25<br />

H54 TF45<br />

MG12<br />

TN35<br />

TI25<br />

H54<br />

TF45<br />

MG12<br />

TF46<br />

Steel Stainless steel Grey cast iron / Aluminium<br />

M<br />

K<br />

H4<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

GROOVE MILLING by circular interpolation<br />

MILLING OF A LINEAR GROOVE - EXTERNAL<br />

s z<br />

= h m<br />

√ 2r a r<br />

s = n • z • s z<br />

mm/min<br />

H<br />

Cos φ° = r2 + [R + r - a r<br />

] 2 - R 2 φ°<br />

2r [R + r - a r<br />

]<br />

L = • 2r • φ° mm<br />

360°<br />

Length <strong>of</strong> cut<br />

t =<br />

A T<br />

n • z • A z<br />

min<br />

Time for cut (for A T<br />

)<br />

A Z<br />

= L • h м<br />

mm 2 s' 2<br />

= s' 1<br />

Area <strong>of</strong> chip<br />

s' 1<br />

= • 2 (R+r-a r ) mm/min<br />

t<br />

Feed rate <strong>of</strong> tool centre<br />

A T<br />

= [R 2 -(R-a r<br />

) 2 ] mm 2<br />

Area <strong>of</strong> groove section<br />

R - a r<br />

R + r - a r<br />

mm/min<br />

Feed rate <strong>of</strong> tool tip<br />

HCT (HORN Circular Technology)<br />

- safe and fast -<br />

Your cutting data for groove <strong>milling</strong> by circular interpolation <strong>of</strong> internal and external grooves as well as groove <strong>milling</strong><br />

<strong>of</strong> linear grooves.<br />

System requirements from Windows 95. Available on CD-ROM.<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

H5

GROOVE MILLING by circular interpolation<br />

MILLING OF AN INTERNAL GROOVE<br />

H<br />

Cos [180° - φ°] = r2 + [R + a r<br />

- r] 2 - R 2 180° - φ° φ°<br />

2r [R + a r<br />

- r]<br />

L = • 2r • φ° mm<br />

360°<br />

Length <strong>of</strong> cut<br />

t =<br />

A T<br />

n • z • A z<br />

min<br />

Time for cut (for A T<br />

)<br />

A Z<br />

= L • h m<br />

mm 2 s' 2<br />

= s' 1<br />

Area <strong>of</strong> chip<br />

s' 1<br />

= • 2 (R+r-a r ) mm/min<br />

t<br />

Feed rate <strong>of</strong> tool centre<br />

A T<br />

= [R 2 -(R-a r<br />

) 2 ] mm 2<br />

Area <strong>of</strong> groove section<br />

R - a r<br />

R + r - a r<br />

mm/min<br />

Feed rate <strong>of</strong> tool tip<br />

Specification<br />

ISO Specification Specification ISO Specification<br />

Feed rate<br />

Revolutions<br />

Number <strong>of</strong> teeth<br />

Feed/tooth<br />

medium thickness <strong>of</strong><br />

chip<br />

radial depth <strong>of</strong> cut<br />

r r<br />

s'<br />

v f<br />

Radius <strong>of</strong> cutter<br />

a r<br />

a e<br />

n<br />

n<br />

Radius <strong>of</strong> workpiece<br />

R<br />

R<br />

z<br />

s z<br />

z<br />

f z<br />

Feed rate <strong>of</strong> tool centre<br />

s‘ 1<br />

v f 3<br />

h m<br />

h m<br />

Feed rate <strong>of</strong> tool tip<br />

s‘ 2<br />

v f2<br />

H6<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

Available METRIC size carbide and tungsten<br />

alloy shanks - Summary<br />

Dimensions in mm Part number Inserts (inch and metric) Use Page<br />

l 1<br />

d g6<br />

l 2<br />

d 1<br />

Type t max<br />

Ds<br />

130 12 40 11 M116.0012.01B<br />

130 12 56 11 M116.0012.02B<br />

130 16 40 11 M116.0016.01B/E<br />

130 16 56 11 M116.0016.02B/E<br />

150 16 80 11 M116.0016.03B/E<br />

80 12 21 6 M306.0012.01B/E/A<br />

90 12 30 6 M306.0012.02B/E/A<br />

100 12 42 6 M306.0012.03B/E/A<br />

116 4.3 20.4 A53<br />

116 4.3 20.4 A53<br />

108/306 1.0/2.5 9.6/11.7 A3 - A4<br />

100 7.5 - 6 M306.0707.03A<br />

D3; E2<br />

108/306 0.85/2.0 9.3/11.7<br />

120 10 - 6 M306.1010.03A E2<br />

90 12 30 7.3 M306.0712.02B/E/A<br />

100 16 25 7.3 M306.0716.01/B/E/A<br />

108/306 0.7/2.0 9.6/11.7 A3 - A4; D3<br />

60 10 15.2 6 M306.ST10.01A 108/306 1.0/2.5 9.4/11.7 A5<br />

95 12 29 8 M308.0012.01B/E/A<br />

110 12 42 8 M308.0012.02B/E/A<br />

120 12 56 8 M308.0012.03B/E/A<br />

111/308/608 2.3/3.5 13.4/15.7 A23-A24<br />

160 12 - - M308.0012.07A 111/308/608 2.3/3.5 13.4/15.7 D11; E8<br />

110 12 42 9.5 M308.1012.02B/E/A<br />

110 16 33 9.5 M308.1016.01B/E/A<br />

60 10 17.7 8 M308.ST10.01A<br />

70 13 25.7 8 M308.ST13.01A<br />

100 12 32 9 M311.0012.01B/E/A<br />

100 12 45 9 M311.0012.02B/E/A<br />

120 12 64 9 M311.0012.03B/E/A<br />

111/308 1.5/2.7 13.4/15.7 A23-A24; D11<br />

111/308 2.3/3.5 13.4/15.7 A25<br />

311/611 3.5/2.5 17.7 A39-A40<br />

90 16 25 9 M311.0016.00B/E 311 3.6 17.0 G3<br />

100 16 32 9 M311.0016.01B/E/A<br />

110 16 45 9 M311.0016.02B/E/A<br />

130 16 64 9 M311.0016.03B/E/A<br />

110 16 32 13 M311.0016.04B/E/A<br />

130 16 45 13 M311.0016.05B/E/A<br />

60 10 17.7 9 M311.ST10.01A<br />

311/611 3.5/2.5 17.7 A39-A40<br />

311/611 1.5 17.7 A39-A40; D21<br />

70 13 25.7 9 M311.ST13.01A 311/611 3.5 17.7<br />

A41<br />

80 16 25.7 9 M311.ST16.01A<br />

100 12 - - M313.0012.01B/E/A<br />

130 12 - - M313.0012.02B/E/A<br />

313/613 4.5/3.2 21.7 A59-A60<br />

93 16 30 11.5 M313.0016.00B/E 313 4.75 21.7 G7<br />

100 16 42 12 M313.0016.01B/E/A<br />

130 16 60 12 M313.0016.02B/E/A<br />

160 16 85 12 M313.0016.03B/E/A<br />

160 16 20 12 M313.0016.07A<br />

110 20 45 16 M313.0020.04B/E<br />

130 20 60 16 M313.0020.05B/E<br />

313/613 4.5/3.2 21.7 A59-A60<br />

313/613 2.5 21.7 D35<br />

H<br />

Dimensions in mm<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

H7

Available METRIC size carbide and tungsten<br />

alloy shanks - Summary<br />

Dimensions in mm Part number Inserts (inch and metric) Use Page<br />

l 1<br />

d g6<br />

l 2<br />

d 1<br />

Type t max<br />

Ds<br />

60 10 10.7 11.3 M313.ST10.01A<br />

70 13 25.7 11.3 M313.ST13.01A<br />

80 16 25.7 11.3 M313.ST16.01A<br />

120 9 - - M328.0909.01A<br />

100 12 36 9 M328.0912.01A<br />

100 16 42 14.3 M328.0016.01B/E/A<br />

130 16 60 14.3 M328.0016.02B/E/A<br />

160 16 85 14.3 M328.0016.03B/E/A<br />

100 20 42 14.3 M328.0020.01B/E/A<br />

130 20 60 14.3 M328.0020.02B/E/A<br />

160 20 85 14.3 M328.0020.03B/E/A<br />

313/613 4.85 21.7 A61<br />

328/628 9.3 28 A79<br />

325/328/628 5.0/6.4/4.3 24.8/27.7 A77 - A78<br />

104 20 35 13.5 M328.0020.00B/E 328 6.5 27.7 G10<br />

H<br />

130 20 20 15 SM328.0020.05B/E<br />

6.0<br />

145 20 - - SM328.0020.06B/E 3.5<br />

328<br />

160 20 20 15 SM328.0020.07B/E 6.0<br />

27.7 D43<br />

200 20 - - SM328.0020.08B/E 3.5<br />

70 13 10.7 14 M328.ST13.01A<br />

100 20 35.7 14 M328.ST20.01A<br />

328/628 6.0 27.7 A80<br />

100 16 42 16 M332.0016.01A<br />

130 16 60 16 M332.0016.02A<br />

160 16 85 16 M332.0016.03A<br />

100 20 42 20 M332.0020.01A<br />

332 8.5 31.7 A92<br />

130 20 60 20 M332.0020.02A<br />

160 20 85 20 M332.0020.03A<br />

100 12 32 11 M332.0012.2.01A<br />

100 16 32 11 M332.0016.2.01A<br />

332 10 31.7<br />

A93<br />

70 13 25 11 M332.ST13.2.01A A94<br />

100 20 40 17.5 M335.0020.01B/A<br />

130 20 60 17.5 M335.0020.02B/A/E<br />

335 7.9/8.0 34.7 A104 - A105<br />

Dimensions in mm<br />

H8<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

Available INCH size carbide and tungsten<br />

alloy shanks - Summary<br />

Diemsnions in inch Part number Inserts (inch and metric) Use Page<br />

l 1<br />

d g6<br />

l 2<br />

d 1<br />

Type t max<br />

Ds<br />

3.150 .500 .827 .236 MU306.0500.01B 108/306 .039/.098 .378/.461<br />

3.543 .500 1.181 .236 MU306.0500.02B 108/306 .039/.098 .378/.461 A2; D2<br />

3.937 .500 1.654 .236 MU306.0500.03B 108/306 .039/.098 .378/.461<br />

3.937 .625. .984 .287 MU306.0625.01B 108/306 .028/.078 .378/.461<br />

3.740 .500 1.142 .315 MU308.0500.01B 111/308 .091/.138 .528/.618<br />

4.331 .500 1.654 .315 MU308.0500.02B 111/308 .091/.138 .528/.618 A22; D10<br />

4.724 .500 2.205 .315 MU308.0500.03B 111/308 .091/.138 .528/.618<br />

4.331 .625 1.299 .315 MU308.0625.01B 111/308 .091/.138 .528/.618<br />

3.937 .500 1.260 .354 MU311.0500.01B 311/611 .138 .697<br />

3.937 .500 1.772 .354 MU311.0500.02B 311/611 .138 .697 A38<br />

4.724 .500 2.520 .354 MU311.0500.03B 311/611 .138 .697<br />

3.543 .625 .984 .354 MU311.0625.00B 311 .143 .669 G2<br />

3.937 .625 1.260 .354 MU311.0625.01B 311/611 .138 .697<br />

4.331 .625 1.772 .354 MU311.0625.02B 311/611 .138 .697 A38<br />

5.118 .625 2.520 .354 MU311.0625.03B 311/611 .138 .697<br />

4.331 .625 1.260 .512 MU311.0625.04B 311 .059 .697 A38; D20<br />

5.118 .625 1.772 .512 MU311.0625.05B 311 .059 .697<br />

6.301 .500 - .354 MU311.1212.07A 313/613 .177 .854<br />

H<br />

3.937 .500 - - MU313.0500.01B 313/613 .177 .854 A58<br />

5.118 .500 - - MU313.0500.02B 313/613 .177 .854<br />

3.661 .625 1.181 .453 MU313.0625.00B 313 .187 .787 G6<br />

3.937 .625 1 .654 .472 MU313.0625.01B 313/613 .177 .854<br />

5.118 .625 2 .362 .472 MU313.0625.02B 313/613 .177 .854 A58<br />

6.299 .625 3 .346 .472 MU313.0625.03B 313/613 .177 .854<br />

4.331 .750 1 .772 .630 MU313.0750.04B 313/613 .098 .854 D34<br />

5.118 .750 2 .559 .630 MU313.0625.05B 313/613 .098 .854<br />

7.874 .625 - .445 MU313.1515.08A 313/613 .098 .854<br />

3.937 .500 - .563 MU328.0500.01B 328/628 .256 1.091<br />

5.118 .500 - .563 MU328.0500.02B 328/628 .256 1.091<br />

3.937 .625 1 .654 .563 MU328.0625.01B 328/628 .256 1.091 A76<br />

5.118 .625 2 .362 .563 MU328.0625.02B 328/628 .256 1.091<br />

6.299 .625 3 .346 .563 MU328.0625.03B 328/628 .256 1.091<br />

6.299 .750 3 .346 .563 MU328.0750.03B 328/628 .256 1.091<br />

4.094 .750 1.378 .531 MU328.0750.00B 328 .256 .945 G9<br />

5.118 .750 .787 .591 SMU328.0750.05B 328 .236 1.091<br />

5.709 .750 - - SMU328.0750.06B 328 .138 1.091<br />

6.299 .750 .787 .591 SMU328.0750.07B 328 .236 1.091 D42<br />

7.874 .750 - - SMU328.0750.08B 328 .138 1.091<br />

Dimensions in inch<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

H9

CUTTING DATA<br />

Standard values for cutting speeds v c<br />

and medium thickness h m<br />

for calculating feed rates by calculating cutting programm »HCT«.<br />

Material<br />

P<br />

Carbon steel<br />

Hardness Brinell<br />

Cutting speeds v c<br />

(sfm)<br />

refering to carbide grade<br />

and coating<br />

MG12<br />

TN35<br />

TI25<br />

TF45<br />

*H35<br />

0.2% C 140 - 790 650-1150<br />

0.4% C 180 - 690 650-980<br />

medium thickness <strong>of</strong> chip h m<br />

Indexable Insert Type 314<br />

Insert Type<br />

311/313/328/108/111/ 116<br />

very rigid rigid not rigid very rigid rigid not rigid<br />

0.6% C 200 - 520 500-820<br />

annealed 180 - 490 590<br />

.0039<br />

.0020<br />

.0012<br />

.0020<br />

.0012<br />

.0004<br />

Alloyed steel<br />

quenched 280 - 390 520<br />

quenched 350 - 230 -<br />

H<br />

high alloyed steel<br />

(>5%)<br />

Cast steel<br />

annealed 200 - 230 -<br />

hardened - - - - - - - - - -<br />

unalloyed 180 80 430 -<br />

alloyed 220 70 390 -<br />

M<br />

K<br />

Stainless steel<br />

Cast iron<br />

martensitic, ferritic 200 80 590 -<br />

austenitic 180 70 390 -<br />

low tensile strength 180 70 330 -<br />

high tensile strength 250 60 390 -<br />

Spheroidal graphite<br />

cast iron<br />

ferritic 160 70 330 -<br />

perlitic 250 - 300 -<br />

Malleable cast iron<br />

S<br />

Heat resistant alloy<br />

(Fe)<br />

ferritic 125 60 330 -<br />

perlitic 225 70 200 -<br />

annealed 200 40 260 -<br />

hardened 275 30 - -<br />

.0039<br />

.0020<br />

.0012<br />

.0020<br />

.0012<br />

.0004<br />

Heat resistant alloy<br />

(Ni, Co)<br />

annealed 250 20 130 -<br />

hardened 350 15 - -<br />

N<br />

Al-alloy<br />

not heat treatable 30-80 550 2600 -<br />

heat treatable 80-120 220 980 -<br />

Al-cast-alloy<br />

not heat treatable 80 220 980 -<br />

heat treatable 100 100 660 -<br />

H10<br />

Copper-alloy<br />

not heat treatable 90 120 - -<br />

heat treatable 100 100 - -<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

*Cermet only indexable insert type 314 available

COMPONENT<br />

Torque screw driver with scale<br />

- variable torque setting<br />

- adjusted torque is shown on display<br />

D 15 VL<br />

Model 1-5 Nm<br />

The Torque can be infinitely adjusted with a special torque<br />

setter (id.) Ergonomical formed gives perfect handling<br />

abilities. Acustic signal when setted torque is reached.<br />

(Standard: EN ISO 6798, BS EN 26789, ASME B 107.14.M.)<br />

(Precision: ± 6 %)<br />

D 28 VL<br />

Model 2-8 Nm<br />

Torque screw driver with scale<br />

- variable torque setting<br />

- adjusted torque is shown on display<br />

The Torque can be infinitely adjusted with a special torque<br />

setter (id.) Ergonomical formed gives perfect handling<br />

abilities. Acustic signal when setted torque is reached.<br />

(Standard: EN ISO 6798, BS EN 26789, ASME B 107.14.M.)<br />

(Precision: ± 6 %)<br />

Torque setter<br />

ED 28 VL<br />

Device for setting the required torque.<br />

Handle: Celluloseacetat with micro structured surface<br />

Blade: Octogonal (8 flats) blade, hardened galvanized<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

O1<br />

O

COMPONENT<br />

Blade for TORX-Plus screws<br />

DT6PK<br />

DT7PK<br />

DT8PK<br />

DT9PK<br />

DT10PK<br />

DT15PK<br />

DT20PK<br />

DT25PK<br />

Blade:<br />

Utilization:<br />

High quality Chrom-Vanadium steel,<br />

through hardened, chrome plated.<br />

Wiha Chrom Blade guarantees maximum<br />

precison.<br />

Colored code green<br />

For controlled screw setting with definite torque<br />

in combination with Wiha torque screw driver<br />

handle.<br />

Blade for allen screws<br />

DSW15K<br />

DSW20K<br />

DSW25K<br />

DSW30K<br />

DSW40K<br />

Blade:<br />

Utilization:<br />

High quality chrom-vanadium steel,<br />

through hardened, chrome plated.<br />

Wiha Chrom Blade guarantees maximum<br />

precison.<br />

Colored code red<br />

controlled screw setting with definite torque in<br />

combination with Wiha torque screw driver<br />

handel<br />

D14ZBK<br />

Universal Bitholder<br />

For S.DM08, S.DM10 and S.DM12 also<br />

for all C6,3 and E6,3 (1/4") Bits<br />

Blade: High quality Chrome-Vanadium steel,<br />

through hardened, chrome plated.<br />

Collar:<br />

Utilization:<br />

Stainless steel<br />

For controlled screw setting with definite torque<br />

in combination with torque screw driver handle.<br />

O<br />

O2<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

COMPONENT<br />

Universal Bitholder with T-handle<br />

For S.DM10 and S.DM12<br />

also for all C6,3 and E6,3 (1/4") Bits<br />

Blade: High quality Chrome-Vanadium steel,<br />

through hardened, chrome plated.<br />

Collar: Stainless steel<br />

Utilization: For controlled opening<br />

14ZQK<br />

Torque screw driver with scale<br />

- variable torque setting<br />

- adjusted torque is shown on display<br />

The Torque can be infinitely adjusted with a special torque<br />

setter (id.) Ergonomical formed gives perfect handling<br />

abilities. Acustic signal when setted torque is reached.<br />

(Standard: EN ISO 6798, BS EN 26789, ASME B 107.14.M.)<br />

(Precision: ± 6 %)<br />

D515QL<br />

Model 5-15 Nm<br />

ED515QL<br />

Torque setter<br />

Device for setting the required torque.<br />

Handle: Celluloseacetat with micro structured surface<br />

Blade: Octogonal (8 flats) blade, hardened galvanized<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN<br />

O3<br />

O

COMPONENT<br />

Universal Bitholder<br />

For S.DM08, S.DM10 and S.DM12 also<br />

for all C6,3 and E6,3 (1/4") Bits<br />

D14ZBQ<br />

Blade:<br />

Collar:<br />

Utilization:<br />

High quality Chrome-Vanadium steel,<br />

through hardened, chrome plated.<br />

Stainless steel<br />

For controlled screw setting with definite torque<br />

in combination with torque screw driver handle.<br />

Blade for TORX-Plus screws<br />

DT15PQ<br />

DT20PQ<br />

DT25PQ<br />

DT27PQ<br />

DT30PQ<br />

Blade:<br />

Utilization:<br />

High quality Chrom-Vanadium steel,<br />

through hardened, chrome plated.<br />

Wiha Chrom Blade guarantees maximum<br />

precison.<br />

Colored code green<br />

For controlled screw setting with definite<br />

torque in combination with Wiha torque screw<br />

driver handle.<br />

O<br />

O4<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

METAL CUTTING SAFETY<br />

During metal cutting "hot flying chips" may be projected from the workpiece<br />

or a rotating part <strong>of</strong> the machine tool. If carbide is subjected to over-stress<br />

or severe impact, it may fracture causing small fragments to be dispelled.<br />

In such instances, certains precautions should be implemented to protect<br />

the operator(s) and/or observer(s) against "hot flying chips.<br />

Boring operations or applications "tempts" the operator to "lean over" the<br />

rotating workpiece to check the cutting action. Extra caution should be<br />

exercised in doing this and it is recommended that no one practice this<br />

habit while tools or machinery or both are spinning, turning, rotating etc.<br />

Grinding products in this catalog will produce dust and/or mist that may be<br />

hazardous. See material data safety sheets (available upon request).<br />

HORN <strong>USA</strong> <strong>Inc</strong>. has no control over conditions to which it's products may<br />

be or subjected to. Therefore it is highly recommended that the user <strong>of</strong><br />

HORN <strong>USA</strong> <strong>Inc</strong>. products listed in this catalog and all the literature <strong>of</strong><br />

this company, abide by the standards <strong>of</strong> use for their particular cutting<br />

machines and commonly used safety precautions.<br />

Designs and/or specifications <strong>of</strong> products listed in this catalog and all<br />

the literature <strong>of</strong> HORN <strong>USA</strong> <strong>Inc</strong>. are subject to change without notice.<br />

Any modification <strong>of</strong> these products by the customer or user may void<br />

specifications and guarantees listed.<br />

HORN <strong>USA</strong> <strong>Inc</strong>. cautions every user and/or observer to wear safety<br />

glasses when using any product listed in this catalog and all the literature<br />

<strong>of</strong> HORN <strong>USA</strong> <strong>Inc</strong>. which made be distributed in conjunction with any<br />

HORN product.<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN

INDEX<br />

Type Chapter page<br />

020 N26<br />

05 N7<br />

105 N11-N20,N32-N37<br />

108 A7-A9,D4,E3<br />

110 N21<br />

111 A27-A29,D11,D14,D17,E9<br />

116 A54-A56,D29<br />

23 N31<br />

306 A10-A18,D5-D6,E4<br />

308 A30-A34,D12,E10<br />

311 A43-A44,A47-A49,D21,D23-D24,E15,G4-G5<br />

313 A63-A64,A66,A68-A72,D33,D35-D36,E19,G8<br />

314 B15-B17,C8-C9,D48,J16-J17<br />

325 A82<br />

328 A83-A84,A87-A88,D41,G11<br />

332 A96-A97,23-24<br />

335 A106<br />

380 B3,B5,B9,D44,D46<br />

380...IK B6-B7<br />

381 B13,J2-J11,J14<br />

382 C3-C4<br />

383 C6-C7<br />

606 A19-A20,D7,E5,6-7<br />

608 A35,D13,D15,E11<br />

611 A45-A46,D22,E16,F4<br />

613 A67,D34,D37,E20,F8<br />

628 A85-A86,A89,D42,E23,F12<br />

632 A98-A99<br />

636 A100-A101<br />

A110 N38<br />

ABS..380 B11<br />

B105 N8-N9, N41-N48<br />

B110 N10, N49<br />

BKT N25,N29-N30<br />

DA31 L12<br />

DA32 L13<br />

DAM31 L2-L4,L6-L7<br />

DAM32 L3-L4,L6-L7<br />

DM008 K3,K5,K7<br />

DM010 K13,K15,K17<br />

DM012 K23,K25,K27<br />

DM208 K8-K11<br />

DM210 K18-K21<br />

DM212 K28-K31<br />

DMU008 K2,K4,K6<br />

DMU010 K12,K14,K16<br />

DMU012 K22,K24,K26<br />

DSA M58-M60<br />

DSAK M62-M63<br />

DSAKH M61<br />

DSAR M64<br />

DSAT M65<br />

DSDH M32<br />

DSDS M31<br />

DSF M42-M43<br />

DSK M24,M26-M27<br />

DSKK M6<br />

DSKL M25<br />

DSKM M28-M30<br />

DSKMK M10<br />

DSM M37<br />

DSMK M8<br />

DSML M40<br />

DSMMK M11<br />

DSMR M38-M39<br />

DSMRK M9<br />

Type<br />

DSP<br />

DSPK<br />

DSPL<br />

DSPM<br />

DSPT<br />

DSR<br />

DSRF<br />

DSRR<br />

DST<br />

DSTK<br />

HSK..380<br />

L311<br />

L313<br />

M116<br />

M275<br />

M306<br />

M306.ER<br />

M306.ST<br />

M308<br />

M308.ER<br />

M308.ST<br />

M310<br />

M311<br />

M311.ER<br />

M311.ST<br />

M313<br />

M313.ER<br />

M313.ST<br />

M328<br />

M328.ER<br />

M328.ST<br />

M332<br />

M332.ER<br />

M335<br />

MD<br />

MU116<br />

MU306<br />

MU308<br />

MU310<br />

MU311<br />

MU313<br />

MU328<br />

N314<br />

S275<br />

S310<br />

SM328<br />

U108<br />

U111<br />

U116<br />

U306<br />

U308<br />

U311<br />

U313<br />

U314<br />

U325<br />

U328<br />

U380<br />

U381<br />

U382<br />

U383<br />

Chapter page<br />

M51-M52,M55<br />

M48-M49<br />

M55<br />

M53-M54<br />

M50<br />

M41<br />

M44<br />

M45<br />

M33-M36<br />

M7<br />

B10<br />

A50<br />

A73-A74<br />

A53,D26<br />

J12-J13<br />

A3-A4,D3,E2<br />

A6<br />

A5<br />

A23-A24,D9,E8<br />

A26<br />

A25<br />

C13,C15<br />

A39-A40,D19,F2,G3<br />

A42,F3<br />

A41<br />

A59-A60,D31,F6,G7<br />

A62,F7<br />

A61<br />

A77-A79,E22,F10,G10<br />

A81,F11<br />

A80<br />

A92-A94<br />

A95<br />

A104-A105<br />

L8-L11<br />

A52,D25<br />

A2,D2<br />

A22,D8<br />

C12,C14<br />

A38,D18,E14,G2<br />

A58,D30,E18,G6<br />

A76,G9<br />

C8,J16<br />

J15<br />

C16<br />

D38<br />

A7-A9<br />

A27-A29,D16<br />

A54,A56,D28<br />

A10,A18<br />

A30,A34<br />

A43,A49<br />

A64-A65,A72<br />

B14<br />

A82<br />

A83<br />

B2,B4,B8,D43,D45<br />

B12<br />

C2<br />

C5<br />

In the UNITED STATES call us toll free<br />

1 - 888 - 818 HORN