利用稀土æå‡é¦™æ¸¯å‰µæ–°åŠç§‘技工æ¥çš„ç–ç•¥å¯è¡Œæ€§ç ”究 - 香港工æ¥ç¸½æœƒ

利用稀土æå‡é¦™æ¸¯å‰µæ–°åŠç§‘技工æ¥çš„ç–ç•¥å¯è¡Œæ€§ç ”究 - 香港工æ¥ç¸½æœƒ

利用稀土æå‡é¦™æ¸¯å‰µæ–°åŠç§‘技工æ¥çš„ç–ç•¥å¯è¡Œæ€§ç ”究 - 香港工æ¥ç¸½æœƒ

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

grow. The rotating particles develop layer by layer into<br />

larger spherical particles. After drying, the green spheres<br />

are calcined to obtain higher mechanical strength.<br />

Sometimes some binder and cement are used to make<br />

the layers adhere better. As smaller particles can be made<br />

more easily by granulation or extrusion than by tabletting,<br />

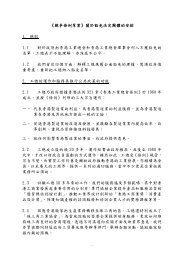

these are the preferred methods of forming. Figure 14<br />

shows a typical machine used to form catalyst particles by<br />

granulation.<br />

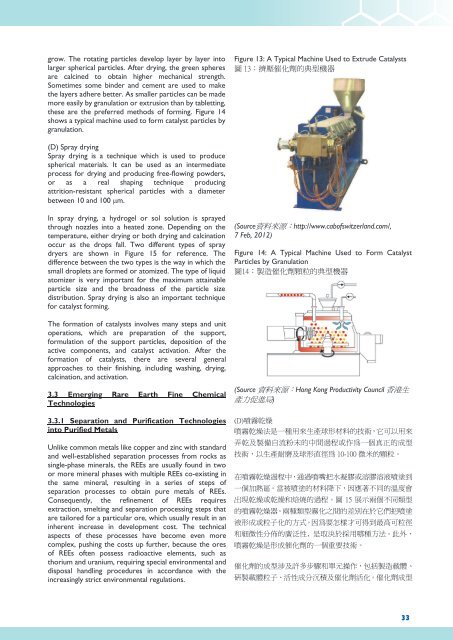

Figure 13: A Typical Machine Used to Extrude Catalysts<br />

圖 13: 擠 壓 催 化 劑 的 典 型 機 器<br />

(D) Spray drying<br />

Spray drying is a technique which is used to produce<br />

spherical materials. It can be used as an intermediate<br />

process for drying and producing free-flowing powders,<br />

or as a real shaping technique producing<br />

attrition-resistant spherical particles with a diameter<br />

between 10 and 100 m.<br />

In spray drying, a hydrogel or sol solution is sprayed<br />

through nozzles into a heated zone. Depending on the<br />

temperature, either drying or both drying and calcination<br />

occur as the drops fall. Two different types of spray<br />

dryers are shown in Figure 15 for reference. The<br />

difference between the two types is the way in which the<br />

small droplets are formed or atomized. The type of liquid<br />

atomizer is very important for the maximum attainable<br />

particle size and the broadness of the particle size<br />

distribution. Spray drying is also an important technique<br />

for catalyst forming.<br />

(Source 資 料 來 源 :http://www.cabofswitzerland.com/,<br />

7 Feb, 2012)<br />

Figure 14: A Typical Machine Used to Form Catalyst<br />

Particles by Granulation<br />

圖 14: 製 造 催 化 劑 顆 粒 的 典 型 機 器<br />

The formation of catalysts involves many steps and unit<br />

operations, which are preparation of the support,<br />

formulation of the support particles, deposition of the<br />

active components, and catalyst activation. After the<br />

formation of catalysts, there are several general<br />

approaches to their finishing, including washing, drying,<br />

calcination, and activation.<br />

3.3 Emerging Rare Earth Fine Chemical<br />

Technologies<br />

3.3.1 Separation and Purification Technologies<br />

into Purified Metals<br />

Unlike common metals like copper and zinc with standard<br />

and well-established separation processes from rocks as<br />

single-phase minerals, the REEs are usually found in two<br />

or more mineral phases with multiple REEs co-existing in<br />

the same mineral, resulting in a series of steps of<br />

separation processes to obtain pure metals of REEs.<br />

Consequently, the refinement of REEs requires<br />

extraction, smelting and separation processing steps that<br />

are tailored for a particular ore, which usually result in an<br />

inherent increase in development cost. The technical<br />

aspects of these processes have become even more<br />

complex, pushing the costs up further, because the ores<br />

of REEs often possess radioactive elements, such as<br />

thorium and uranium, requiring special environmental and<br />

disposal handling procedures in accordance with the<br />

increasingly strict environmental regulations.<br />

(Source 資 料 來 源 :Hong Kong Productivity Council 香 港 生<br />

產 力 促 進 局 )<br />

(D) 噴 霧 乾 燥<br />

噴 霧 乾 燥 法 是 一 種 用 來 生 產 球 形 材 料 的 技 術 , 它 可 以 用 來<br />

弄 乾 及 製 備 自 流 粉 末 的 中 間 過 程 或 作 為 一 個 真 正 的 成 型<br />

技 術 , 以 生 產 耐 磨 及 球 形 直 徑 為 10-100 微 米 的 顆 粒 。<br />

在 噴 霧 乾 燥 過 程 中 , 通 過 噴 嘴 把 水 凝 膠 或 溶 膠 溶 液 噴 塗 到<br />

一 個 加 熱 區 。 當 被 噴 塗 的 材 料 降 下 , 因 應 著 不 同 的 溫 度 會<br />

出 現 乾 燥 或 乾 燥 和 焙 燒 的 過 程 。 圖 15 展 示 兩 個 不 同 類 型<br />

的 噴 霧 乾 燥 器 。 兩 種 類 型 霧 化 之 間 的 差 別 在 於 它 們 把 噴 塗<br />

液 形 成 或 粒 子 化 的 方 式 。 因 為 要 怎 樣 才 可 得 到 最 高 可 粒 徑<br />

和 細 微 性 分 佈 的 廣 泛 性 , 是 取 決 於 採 用 哪 種 方 法 。 此 外 ,<br />

噴 霧 乾 燥 是 形 成 催 化 劑 的 一 個 重 要 技 術 。<br />

催 化 劑 的 成 型 涉 及 許 多 步 驟 和 單 元 操 作 , 包 括 製 造 載 體 、<br />

研 製 載 體 粒 子 、 活 性 成 分 沉 積 及 催 化 劑 活 化 。 催 化 劑 成 型<br />

33