ATMOS S 61 Servant ENT workstation (GA-en) - This is the ATMOS ...

ATMOS S 61 Servant ENT workstation (GA-en) - This is the ATMOS ...

ATMOS S 61 Servant ENT workstation (GA-en) - This is the ATMOS ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

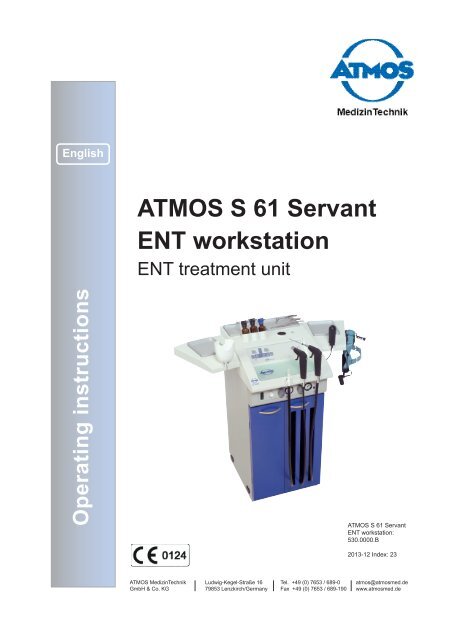

Engl<strong>is</strong>h<br />

<strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong><br />

<strong>ENT</strong> <strong>workstation</strong><br />

<strong>ENT</strong> treatm<strong>en</strong>t unit<br />

Operating instructions<br />

<strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong><br />

<strong>ENT</strong> <strong>workstation</strong>:<br />

530.0000.B<br />

2013-12 Index: 23<br />

<strong>ATMOS</strong> MedizinTechnik<br />

GmbH & Co. KG<br />

Ludwig-Kegel-Straße 16<br />

79853 L<strong>en</strong>zkirch/Germany<br />

Tel. +49 (0) 7653 / 689-0<br />

Fax +49 (0) 7653 / 689-190<br />

atmos@atmosmed.de<br />

www.atmosmed.de

Fur<strong>the</strong>r information, accessories, consumables and<br />

spare parts are available from:<br />

<strong>ATMOS</strong><br />

MedizinTechnik GmbH & Co. KG<br />

Ludwig-Kegel-Straße 16<br />

79853 L<strong>en</strong>zkirch<br />

Germany<br />

Tel. +49 (0) 76 53 / 689-0<br />

Fax: +49 (0) 76 53 / 689-190<br />

+49 (0) 76 53 / 689-493 (Service C<strong>en</strong>ter)<br />

atmos@atmosmed.de<br />

www.atmosmed.de

Table of cont<strong>en</strong>ts<br />

1.0 Introduction............................................................................. 5<br />

1.1 Notes on operating instructions 5<br />

1.2 Int<strong>en</strong>ded use 5<br />

1.3 Function 5<br />

1.4 Explanation of symbols 6<br />

2.0 For your safety........................................................................ 7<br />

3.0 Assembly and Starting up...................................................... 8<br />

3.1 Required connections 8<br />

3.2 Connection to electrical power line 8<br />

3.3 Water connection 9<br />

3.4 Water drain 9<br />

3.5 Controls and options at complete equipm<strong>en</strong>t 10<br />

3.6 Back view 11<br />

3.7 Assembly of secretion jar 11<br />

3.8 Adjustm<strong>en</strong>t of front feet 12<br />

3.9 Connections in service room 12<br />

4.0 Operation............................................................................... 13<br />

4.1 On- / Off- Switch 13<br />

4.2 Suction system 13<br />

4.3 Ear rinsing module Hygro<strong>the</strong>rm 16<br />

4.4 Thermal nystagmus stimulation Vario<strong>the</strong>rm 17-18<br />

4.5 Ear rinsing module 37° C basic 19<br />

4.6 Compressed air system 20<br />

4.7 LED light module 21<br />

4.8 Instrum<strong>en</strong>t heating 22<br />

4.9 Clipboard <strong>en</strong>doskopy 23<br />

5.0 Cleaning................................................................................. 24<br />

5.1 G<strong>en</strong>eral information on cleaning and d<strong>is</strong>infection 24<br />

5.2 Recomm<strong>en</strong>ded instrum<strong>en</strong>t d<strong>is</strong>infectants 25<br />

5.3 Recomm<strong>en</strong>ded surface d<strong>is</strong>infectants 25<br />

6.0 Hygi<strong>en</strong>e plan.....................................................................28-29<br />

7.0 Maint<strong>en</strong>ance and servicing.................................................. 30<br />

7.1 Replacing <strong>the</strong> fuse 30<br />

7.2 Replacing bacterial filter 30<br />

7.3 Changing tube cassette of tube pump 30<br />

8.0 Trouble shooting................................................................... 31<br />

9.0 Accessories and consumables............................................ 33<br />

9.1 Accessories 33<br />

9.2 Consumables 33<br />

10.0 Technical specifications....................................................... 34<br />

11.0 D<strong>is</strong>posal................................................................................. 35<br />

12.0 Notes on EMC...................................................................36-38<br />

Declaration of conformity..................................................... 39<br />

3

1.0 ... Introduction<br />

1.1 Notes on operating instructions<br />

These operating instructions contain important notes on how to operate <strong>the</strong> <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong><br />

<strong>ENT</strong> <strong>workstation</strong> safely, correctly and effectively. Their reading helps to avoid r<strong>is</strong>ks, and also to reduce<br />

repair costs and down-time. That increases, amongst o<strong>the</strong>r things, <strong>the</strong> reliability and service-life<br />

of <strong>the</strong> device.<br />

These operating instructions serve not only for new operating personnel to be instructed in its use,<br />

but also for use as a refer<strong>en</strong>ce manual. Reprints (also in extracts) only with perm<strong>is</strong>sion in writt<strong>en</strong><br />

form by <strong>ATMOS</strong>.<br />

These operating instructions must always be kept available near <strong>the</strong> device.<br />

Care and safety inspections in conjunction with professional execution provide for operational safety<br />

and readiness for use of your <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>ENT</strong> <strong>workstation</strong> and are <strong>the</strong>refore a must<br />

besides regular cleaning.<br />

Repair work and safety inspections may be carried out only by expert personnel author<strong>is</strong>ed by<br />

<strong>ATMOS</strong>. By applying only original spare parts you will have <strong>the</strong> guarantee that operational safety,<br />

readiness for work and <strong>the</strong> value of your <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>ENT</strong> <strong>workstation</strong> will be preserved.<br />

● The product <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>ENT</strong> <strong>workstation</strong> bears CE marking CE according to <strong>the</strong> EU<br />

guideline of <strong>the</strong> council for medical products 93/42/EWG and meets <strong>the</strong> basic requirem<strong>en</strong>ts of<br />

annex I of th<strong>is</strong> guideline.<br />

● The quality managem<strong>en</strong>t system applied at <strong>ATMOS</strong> has be<strong>en</strong> certified according to international<br />

standards EN ISO 9001 and EN ISO 13485.<br />

● Prior to start-up please peruse chapter 2.0 „For your safety“, in order to be prepared for any<br />

possible dangerous situations.<br />

1.2 Earmarking<br />

● Main functions:<br />

→ suction<br />

→ ear rinsing<br />

→ compressed-air for medication spraying and<br />

<strong>the</strong>rmal nystagmus stimulation<br />

→ electric power supply for LED-light source<br />

→ medical electric power supply for external devices<br />

● Specifications of <strong>the</strong> main functions:<br />

→ suction at 40 l /min / 760 hPa, alternatively<br />

→ suction at 55 l/min / 920 hPa<br />

→ ear rinsing with 37° max 500 ml/min, alternatively<br />

→ ear rinsing with 37° with vacuum burble system<br />

→ compressed-air for medication spraying, max. 2 bar<br />

→ electric power supply for LED, 700 mA regulated<br />

● Application:<br />

→ for application on human<br />

1.3 Function<br />

The treatm<strong>en</strong>t unit <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>ENT</strong><br />

<strong>workstation</strong> makes modular assembly possible for <strong>the</strong><br />

following functional modules:<br />

- suction system<br />

- compressed-air system<br />

- ear rinsing module 37°C basic<br />

- ear rinsing system (Hygro<strong>the</strong>rm)<br />

- system for <strong>the</strong>rmal nystagmus stimulation<br />

- LED light source <strong>ATMOS</strong> LS 21 LED<br />

- LED head light <strong>ATMOS</strong> HL 21 LED<br />

● Application organ:<br />

→ throat, nose, ear<br />

● Duration of application:<br />

→ short-term<br />

● Application area:<br />

→ In clinics and practices of <strong>ENT</strong> doctors.<br />

● Application restriction:<br />

→ Must not be used for rinsing of paranasal sinuses.<br />

● Application condition:<br />

→ see technical specifi cations<br />

5

...1.0 Introduction<br />

1.4 Explanation of pictures and symbols<br />

Short cuts / symbols contained in th<strong>is</strong> manual<br />

Follow <strong>the</strong> arrows<br />

whilst proceeding,<br />

sequ<strong>en</strong>ce<br />

■<br />

G<strong>en</strong>eral information<br />

Move, plug ... in th<strong>is</strong><br />

direction<br />

Please press where<br />

dot indicates<br />

●<br />

Numeration<br />

Turn, shift ... in th<strong>is</strong><br />

direction<br />

Activate <strong>the</strong> optional<br />

foot switch<br />

→<br />

Subnumeration<br />

Replace<br />

Please read,<br />

important information<br />

Check<br />

click<br />

Engage, check correct<br />

fi t<br />

Pictures contained in th<strong>is</strong> manual<br />

!<br />

Warning, especial dilig<strong>en</strong>t<br />

notice<br />

Mirror quick heater<br />

Ground wire connection<br />

Fuse according to<br />

IEC 47/5016, DIN 30600/0186<br />

Application part type B<br />

Adjustm<strong>en</strong>t<br />

Compressed air<br />

Suction<br />

~<br />

Alternating curr<strong>en</strong>t<br />

On (feed-in, power<br />

connection)<br />

Pot<strong>en</strong>tial equalization<br />

Foot switch<br />

Off (feed-in, power<br />

connection)<br />

6

2.0 For your safety<br />

• Only switch on unit at available water consumption, wh<strong>en</strong><br />

water supply <strong>is</strong> guaranteed!<br />

!<br />

For your safety<br />

• The <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>ENT</strong> <strong>workstation</strong> unit <strong>is</strong><br />

produced according to IEC 601/ EN 60601 and l<strong>is</strong>ted in<br />

<strong>the</strong> following classes:<br />

• VDE Class of protection 1<br />

• Class IIa (EEC 93/42).<br />

• Correct configuration in assembly of country-specific<br />

connections:<br />

gre<strong>en</strong>/yellow: protective conductor (PE)<br />

blue:<br />

neutral conductor (N)<br />

black resp. brown: phase (L)<br />

• Att<strong>en</strong>tion! Mirrorheaters may g<strong>en</strong>erate temperatures<br />

above 40°C!<br />

• The <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>ENT</strong> <strong>workstation</strong> may be<br />

used in superv<strong>is</strong>ed operation by qualified personnel<br />

only which has be<strong>en</strong> author<strong>is</strong>ed by <strong>ATMOS</strong> and which<br />

has be<strong>en</strong> trained for operating <strong>the</strong> appliance (IEC 601-<br />

1/EN 60601-1).<br />

• The mains voltage specified on <strong>the</strong> type plate must<br />

correspond with <strong>the</strong> data of <strong>the</strong> power supply system.<br />

• Make sure prior to every application of <strong>the</strong> equipm<strong>en</strong>t that<br />

it <strong>is</strong> technically safe and in proper condition. Damaged<br />

leads and hoses must be replaced immediately!<br />

• D<strong>is</strong>play instrum<strong>en</strong>ts and valves must be checked for<br />

correct function in regular intervals !<br />

• Inspection of compressed air and vacuum d<strong>is</strong>play by<br />

service technician every 2 years !<br />

• Arrange a sight check every morning for <strong>the</strong> hoses,<br />

collection jars and cables.<br />

Exchange damaged parts!<br />

Only use correct and undamaged line voltages<br />

and ext<strong>en</strong>sion cables.<br />

• Switch off <strong>the</strong> unit before op<strong>en</strong> it and separate it<br />

from <strong>the</strong> line voltage.<br />

• Maximum load for clipboards: 2 kg<br />

• Never leave <strong>the</strong> pati<strong>en</strong>t unatt<strong>en</strong>ded at <strong>the</strong> treatm<strong>en</strong>t unit.<br />

• <strong>Th<strong>is</strong></strong> product <strong>is</strong> not re-steril<strong>is</strong>able. Repeated reuse of<br />

compon<strong>en</strong>ts which are marked with a 2 <strong>is</strong> forbidd<strong>en</strong>.<br />

In case of repeated reuse <strong>the</strong>se compon<strong>en</strong>ts lose <strong>the</strong>ir<br />

function and <strong>the</strong>re <strong>is</strong> a high infection r<strong>is</strong>k.<br />

• In case that <strong>the</strong>re <strong>is</strong> no adapter attached to <strong>the</strong> light<br />

conductor, touching <strong>the</strong> light source with ei<strong>the</strong>r <strong>the</strong><br />

fingers or any tools should be avoided. On <strong>the</strong> one hand<br />

th<strong>is</strong> may damage <strong>the</strong> l<strong>en</strong>ses and on <strong>the</strong> o<strong>the</strong>r hand <strong>the</strong>re<br />

<strong>is</strong> a r<strong>is</strong>k of injury.<br />

• The <strong>ENT</strong> unit requires clean water (drinking-water quality)<br />

for <strong>the</strong> operation. In case <strong>the</strong> clean water cannot be provided<br />

by <strong>the</strong> water supply, a pre-filter has to be installed.<br />

The relevant country specific regulations for <strong>the</strong> instal-lation<br />

have to be considered !<br />

• Please note:<br />

A medical insulating transformer with earth leakage<br />

monitor or any similar safety system acc. to EN 60 601-1<br />

<strong>is</strong> required, if several devices are connected over one<br />

common power supply. The transformer must<br />

correspond to <strong>the</strong> power consumption of all <strong>the</strong> devices<br />

to be connected.<br />

• Do not place used contaminated instrum<strong>en</strong>ts on <strong>the</strong><br />

<strong>ENT</strong> unit except on destined places!<br />

• The ambi<strong>en</strong>t conditions specified in section "Technical<br />

specifications" must be strictly observed!<br />

• Switch off main switch after fin<strong>is</strong>hing work in practice and<br />

close water supply, if pres<strong>en</strong>t.<br />

• Att<strong>en</strong>tion wh<strong>en</strong> working with <strong>en</strong>doscopes near <strong>the</strong> light<br />

sources. Do not look directly into <strong>the</strong> cone of light!<br />

At a conting<strong>en</strong>t light blackout remove <strong>the</strong> <strong>en</strong>doscope out<br />

of <strong>the</strong> area!<br />

• The <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> may be operated only in<br />

rooms used for medical purposes, but not in areas<br />

subject to explosion hazards and in oxyg<strong>en</strong> rich<br />

<strong>en</strong>vironm<strong>en</strong>ts.<br />

• The <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> fully complies with <strong>the</strong> electromagnetic<br />

immunity requirem<strong>en</strong>ts of standard IEC 601-1-2<br />

/ EN 60601-1-2 "Electromagnetic compatibility - Medical<br />

Electrical Equipm<strong>en</strong>t".<br />

• The <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> may not be operated with<br />

units not complying with <strong>the</strong> requirem<strong>en</strong>ts of standard EN<br />

60601-1 "Medical Electrical Equipm<strong>en</strong>t" and EN 60601-<br />

1-2 "Electromagnetic compatibility (Medical Electrical<br />

Equipm<strong>en</strong>t)".<br />

• <strong>ATMOS</strong> <strong>is</strong> not liable for personal injury and damage to<br />

property if<br />

• no original <strong>ATMOS</strong> parts are being used,<br />

• <strong>the</strong> advice for use in <strong>the</strong>se operating instructions <strong>is</strong> not<br />

being observed,<br />

• assembly, new settings, alterations, ext<strong>en</strong>sions and<br />

repairs have be<strong>en</strong> carried out by personnel not author<strong>is</strong>ed<br />

by <strong>ATMOS</strong>.<br />

• These operating instructions correspond with <strong>the</strong> construction<br />

of <strong>the</strong> unit and with <strong>the</strong> curr<strong>en</strong>t status of safetyrelated<br />

standards at <strong>the</strong> time of printing. Proprietary rights<br />

are ex<strong>is</strong>ting for all described circuits, processes, names,<br />

software programs and units..<br />

• Do not constrict <strong>the</strong> air supply on <strong>the</strong> back of <strong>the</strong> unit!<br />

• The ear rinsing modlue 37°C basic must not be actuated<br />

with a 55l-aspiration system!<br />

• Prior to starting <strong>the</strong> treatm<strong>en</strong>t application parts have to be<br />

checked regarding <strong>the</strong>ir temperature.<br />

• It <strong>is</strong> not allowed to use flammable substances with <strong>the</strong><br />

device.<br />

7

3.0 Assembly: Connecting conditions<br />

ca. 250<br />

350<br />

160<br />

Connection to c<strong>en</strong>tral gas supply up to max. 8 bar.<br />

The standard NIST connection for c<strong>en</strong>tral vacuum and c<strong>en</strong>tral compressed air on <strong>the</strong> rear side of <strong>the</strong><br />

device <strong>is</strong> optional, connecting hoses are not included in delivery.<br />

3.1 Required connections for all units of <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong><br />

Unit / Device<br />

<strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>ENT</strong> <strong>workstation</strong><br />

<strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> v<strong>is</strong>ion<br />

<strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> instrum<strong>en</strong>ts<br />

<strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>the</strong>rapy<br />

Water separating system (WTA)<br />

Monitor<br />

Pati<strong>en</strong>t chair<br />

Maximum required connections<br />

1x earthing contact socket outlet<br />

1x fi xed connection<br />

1x earthing contact socket outlet<br />

2x earthing contact socket outlet<br />

1x earthing contact socket outlet<br />

1x earthing contact socket outlet<br />

1x earthing contact socket outlet<br />

3.2 Connection to electrical power line<br />

• According to <strong>the</strong> directions of VDE 0107 and VDE 0100, medically used rooms have to be equipped with<br />

a leakage curr<strong>en</strong>t protective circuit (FI protective circuit) with a nominal leakage curr<strong>en</strong>t of < 0.03 A.<br />

Installation must correspond with VDE 0107.<br />

• The <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>ENT</strong> <strong>workstation</strong> <strong>is</strong> connected to a earthing contact socket outlet which <strong>is</strong> to be<br />

mounted near <strong>the</strong> unit (max. 3 m, see fi g.). Only qualifi ed personnel author<strong>is</strong>ed by <strong>ATMOS</strong> <strong>is</strong> allowed to<br />

proceed th<strong>is</strong>.<br />

• The power consumption of <strong>the</strong> <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>ENT</strong> <strong>workstation</strong> comes to 2.300 VA max.<br />

• An adequate number of socket outlets with earthing contact should be mounted for possible connection of<br />

fur<strong>the</strong>r electrically operated units which may be installed at doctor‘s work station (e.g. installation of an<br />

electrically operated pati<strong>en</strong>t chair, camera, monitor, etc.)<br />

8

3.0 Assembly: Connecting conditions<br />

3.3 Water connection<br />

!<br />

Requirem<strong>en</strong>ts for water supply:<br />

• Easily accessible water tap with hose connection G 3/4“.<br />

• Connection including pipe aeration <strong>is</strong> recomm<strong>en</strong>ded.<br />

• The water which <strong>is</strong> provided by <strong>the</strong> household connection must at least meet <strong>the</strong> WHO guidelines or <strong>the</strong><br />

country-specific guidelines for drinking water.<br />

• Rinse water supply line in order to remove any contamination from <strong>the</strong> system.<br />

• Wh<strong>en</strong> clean water <strong>is</strong> available, connect delivery hose to water tap m<strong>en</strong>tioned above.<br />

• Required pressure in domestic water system: >2 bar, but 3.8 >21.3<br />

• The use of demineral<strong>is</strong>ed water may affect <strong>the</strong> function of <strong>the</strong> waste water d<strong>is</strong>posal!<br />

3.4 Water drain<br />

Requirem<strong>en</strong>ts:<br />

• Perman<strong>en</strong>tly installed connection fitting with G3/4“ external thread.<br />

An anti-syphon trap <strong>is</strong> integrated in <strong>the</strong> unit!<br />

• Connect waste water hose with unit and <strong>the</strong> G3/4“ connection fitting. Thereby fit <strong>en</strong>closed gaskets into <strong>the</strong><br />

screwing.<br />

1730<br />

740<br />

250<br />

445<br />

640<br />

1550<br />

630<br />

730<br />

19<strong>61</strong><br />

2940<br />

979,5<br />

9

3.0 Assembly: Starting up<br />

3.5 Controls and options at complete equipm<strong>en</strong>t<br />

Heating module for<br />

instrum<strong>en</strong>t tray<br />

Nebulization of medications<br />

(compressed air)<br />

Clipboard<br />

<br />

max. 2 kg!<br />

mirror quick heater<br />

LED light source<br />

LED head light<br />

Ear irrigation /<br />

<strong>the</strong>rmal nystagmus<br />

stimulation<br />

Compressed air<br />

Automatic suction<br />

equipm<strong>en</strong>t<br />

On / off switch<br />

Hose rinsing<br />

Adjustm<strong>en</strong>t<br />

vacuum<br />

Adjustm<strong>en</strong>t<br />

compressed air<br />

D<strong>is</strong>play<br />

compressed air<br />

D<strong>is</strong>play<br />

vacuum<br />

The plastic adapter of <strong>the</strong> hose rinsing system () <strong>is</strong> a consumable (REF 506.2228.1), exchange weekly.<br />

It <strong>is</strong> removed by tw<strong>is</strong>ting it out with a slight rotation.<br />

10

3.0 Installation and starting up<br />

3.6 Back view<br />

Plug <strong>the</strong> power cable into <strong>the</strong> non-heating socket.<br />

Please att<strong>en</strong>d also <strong>the</strong> safety instructions for it on<br />

page 7!<br />

3.7 Assembly of secretion jar<br />

Prior to use, check <strong>the</strong> system up on d<strong>en</strong>sity, o<strong>the</strong>rw<strong>is</strong>e it <strong>is</strong> possible that vacuum can not be built up.<br />

insert bacterial<br />

fi lter () into splash<br />

guard ()<br />

insert fl oat () into<br />

<strong>the</strong> splash guard<br />

() protection (not<br />

applicable for 55 l<br />

pump)<br />

put splash guard<br />

into lid<br />

insert suction hose()<br />

impose seal () on,<br />

put lid onto jar ()<br />

connect hose on<br />

grommet ()<br />

3.7.1 Bodywork collection jar<br />

insert grommet<br />

into lid<br />

put quiver horizontal<br />

onto <strong>the</strong> both nipples<br />

fi x hose into<br />

cramp<br />

hose connection (grommet) <br />

340.0057.0<br />

collection jar lid <br />

530.1108.0<br />

seal <br />

320.0013.0<br />

<br />

exhaust hose<br />

(only at automatic)<br />

006.0008.0, 220mm<br />

bacterial filter <br />

340.0054.0<br />

splash guard <br />

312.0827.0<br />

float <br />

000.0069.0<br />

intake for foam prev<strong>en</strong>tion:<br />

The hose attempt with intake cares for <strong>the</strong> liquid<br />

surface to remain quiesc<strong>en</strong>t.<br />

Thereby a lower foaming and a longer fi lter durability<br />

<strong>is</strong> achieved.<br />

secretion collecting container <br />

11

3.0 Installation and starting-up<br />

3.8 Adjustm<strong>en</strong>t of front feet<br />

Adjust <strong>the</strong> screws of <strong>the</strong> feet through <strong>the</strong> boreholes with a fl at-bladed<br />

screwdriver scaled 4-5.<br />

3.9 Connectors in <strong>the</strong> service room<br />

3.9.1 Hoses<br />

insert phone jack into marked jack<br />

insert application parts into <strong>the</strong><br />

border<br />

3.9.2 Footswitch<br />

insert three-hole seal near<br />

<strong>the</strong> supply hose of <strong>the</strong> tap<br />

for ear rinsing<br />

connect water hose in<br />

<strong>the</strong> service compartm<strong>en</strong>t<br />

connect compressed-air hose in <strong>the</strong><br />

service compartm<strong>en</strong>t<br />

First start-up<br />

Prior to shipm<strong>en</strong>t each <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>is</strong> being inspected by <strong>the</strong> manufacturer for function and safety.<br />

In order to make sure that <strong>the</strong> appliance <strong>is</strong> working safely after transport and installation, <strong>the</strong> following points<br />

should be observed: The user should put <strong>the</strong> appliance into operation only if<br />

1. a functional test on <strong>the</strong> appliance at <strong>the</strong> place of operation has be<strong>en</strong> carried out.<br />

2. <strong>the</strong> operating instructions have be<strong>en</strong> read and noticed.<br />

Following transportation at low temperatures <strong>the</strong> appliance must be held for up to fours hours at ambi<strong>en</strong>t<br />

temperature before fi rst start-up. Wh<strong>en</strong> <strong>the</strong> appliance has not be<strong>en</strong> acclimat<strong>is</strong>ed <strong>the</strong> formation of cond<strong>en</strong>sation<br />

water <strong>is</strong> possible and a malfunction might be <strong>the</strong> result.<br />

12

4.0 Operation<br />

4.1 On / off switch<br />

With <strong>en</strong>gaging <strong>the</strong> main switch all integrated<br />

and connected devices are ready.<br />

4.2 Suction system<br />

!<br />

Never drive <strong>the</strong> suction system without bacterial fi lter! Always use <strong>the</strong> splash guard for ext<strong>en</strong>tion of <strong>the</strong> utilization of <strong>the</strong><br />

bacterial fi lter. Incorrect using makes expire <strong>the</strong> guaranty!<br />

Change <strong>the</strong> bacterial fi lter regularly. Advices in section 5.0!<br />

The hose attachm<strong>en</strong>t must be exchanged after each pati<strong>en</strong>t.<br />

4.2.1 Control and d<strong>is</strong>play of <strong>the</strong> suction rate<br />

Adjustm<strong>en</strong>t<br />

vacuum<br />

D<strong>is</strong>play<br />

vacuum<br />

For activation of <strong>the</strong> suction system you have following alternatives:<br />

A)<br />

If you do not have a foot switch connected:<br />

Take handle from holder. By <strong>the</strong> installed light barrier <strong>the</strong> suction system activates automatically.<br />

Set <strong>the</strong> desired vacuum via adjustm<strong>en</strong>t, <strong>the</strong>refor <strong>the</strong> <strong>en</strong>d of <strong>the</strong> suction hose has to be closed. Only in th<strong>is</strong> case a vacuum will<br />

be built up.<br />

4.2.2 Foot switch (530.1080.0)<br />

B)<br />

If you have a foot switch connected:<br />

Take handle from holder. Afterwards push and hold <strong>the</strong> foot switch for activation. Wh<strong>en</strong> releasing, <strong>the</strong> suction system<br />

deactivates again.<br />

Set <strong>the</strong> desired vacuum via adjustm<strong>en</strong>t. Therefor <strong>the</strong> <strong>en</strong>d of <strong>the</strong> suction hose has to be closed. Only in th<strong>is</strong> case a vacuum<br />

will be built up.<br />

4.2.3 Hose rinsing system<br />

at least 30 sec.<br />

After each application rinse <strong>the</strong> suction hose thoroughly. Add <strong>the</strong> suction hose (without canula) with <strong>the</strong> suction nipple to<br />

<strong>the</strong> suction attachm<strong>en</strong>t for <strong>the</strong> hose rinsing and soak up <strong>the</strong> rinsing fl uid at least 30 sec.<br />

13

4.0 Operation<br />

Refilling / Storage container / Hose rinsing<br />

A) Fully automated refilling (530.1060.0)<br />

If required, <strong>the</strong> water storage container will be refi lled automatically.<br />

ATT<strong>ENT</strong>ION:<br />

Make sure that <strong>the</strong> water supply system <strong>is</strong> on and <strong>the</strong> water supply secured !<br />

Do not use any foaming cleaning ag<strong>en</strong>ts respectively d<strong>is</strong>infectants.<br />

B) Manual refilling (530.1050.0)<br />

Fill <strong>the</strong> container with water and/or a non-foaming instrum<strong>en</strong>t d<strong>is</strong>infectant.<br />

4.2.4 Draining of reusable container system<br />

The container system has to be cleansed and d<strong>is</strong>infected regularly.<br />

Advices in section 5.0 ‘Cleaning‘.<br />

A) Manual<br />

Drain <strong>the</strong> collection jar at approx. half level.<br />

Pull <strong>the</strong> collection jar horizontal out of <strong>the</strong> holder in <strong>the</strong> service compartm<strong>en</strong>t and remove <strong>the</strong> suction<br />

hose.<br />

B) Automatic (530.1070.0)<br />

The automatic collection jar draining cares for a self-acting evacuation at an according level.<br />

Bodywork collection jar<br />

hose connection<br />

340.0057.0<br />

intake for foam<br />

prev<strong>en</strong>tion<br />

collection jar lid<br />

530.1108.0<br />

seal<br />

320.0013.0<br />

bacterial filter<br />

340.0054.0<br />

exhaust hose<br />

(only at automatic)<br />

006.0008.0, 220mm<br />

splash guard<br />

312.0827.0<br />

float<br />

000.0069.0<br />

secretion collecting container<br />

The hose attempt with <strong>the</strong> intake cares for <strong>the</strong> liquid<br />

surface to remain quiesc<strong>en</strong>t.<br />

Thereby a lower foaming and a longer fi lter durability<br />

<strong>is</strong> achieved.<br />

14

4.0 Operation<br />

4.2.5 D<strong>is</strong>posable container system<br />

A) Receptal<br />

B) Medi-Vac<br />

15

4.0 Operation<br />

4.3 Ear irrigation module Hygro<strong>the</strong>rm<br />

!<br />

The integrated ear irrigation module Hygro<strong>the</strong>rm features separate operating instructions.<br />

Please note:<br />

Read <strong>the</strong>se separate operating instructions att<strong>en</strong>tively and follow <strong>the</strong> stated notes for your safety to guarantee ideal<br />

and safe use of all functions!<br />

■ If you switch on <strong>the</strong> appliance, a segm<strong>en</strong>t-test will be carried out. For a mom<strong>en</strong>t all LEDs will be activated.<br />

In th<strong>is</strong> time please check <strong>the</strong> function of <strong>the</strong> LEDs optically.<br />

■ Before <strong>the</strong> caloric measurem<strong>en</strong>ts you have to check <strong>the</strong> water pressure at <strong>the</strong> manometer in <strong>the</strong> service room.<br />

It has to be a desired pressure of 2 bar. Beware of overpressure !<br />

!<br />

The ear irrigation hose may only be used with an ear irrigation bowl which has an integrated sieve! It <strong>is</strong> not<br />

suitable for secretion suction.<br />

tulip-shaped ear irrigation bowl<br />

handle ear irrigation system<br />

4.3.1 Ear irrigation module compressed air REF 530.2070.0<br />

!<br />

The ear irrigation bowl with optional, separate suction channel may only be used for suction during ear irrigation<br />

or stimulation. Only <strong>the</strong> ear irrigation bowl with integrated sieve (hole diameter 1 mm at a maximum) may be<br />

used. The suction channel <strong>is</strong> not suitable for any o<strong>the</strong>r suction procedure in <strong>the</strong> medical field! The liquid pump <strong>is</strong><br />

not suitable for sucking off bigger particles like, for example, cerum<strong>en</strong>, etc. Therefore, suction may only be performed<br />

with bowl and sieve.<br />

Greasy and pasty substances can be sucked off but only limited. It <strong>is</strong> recomm<strong>en</strong>ded to clean <strong>the</strong> bowl after each<br />

suction procedure and to rinse it with water (d<strong>is</strong>infectant) in order to prev<strong>en</strong>t <strong>the</strong> pump valves from jamming.<br />

Take out <strong>the</strong> suction nozzle with <strong>the</strong> ear irrigation bowl from <strong>the</strong> susp<strong>en</strong>sion, <strong>the</strong> suction system switches on automatically.<br />

Th<strong>en</strong> apply <strong>the</strong> bowl with <strong>the</strong> lateral cut-out below <strong>the</strong> ear which needs to be irrigated and start irrigation.<br />

Wh<strong>en</strong> <strong>the</strong> suction nozzle <strong>is</strong> put back to <strong>the</strong> susp<strong>en</strong>sion, <strong>the</strong> suction system stops automatically.<br />

Att<strong>en</strong>tion: Please use <strong>the</strong> suction system with ear irrigation bowl only.<br />

4.3.2 Activation of <strong>the</strong> Hygro<strong>the</strong>rm<br />

Take handle from holder. By <strong>the</strong> installed light barrier <strong>the</strong> Hygro<strong>the</strong>rm activates automatically.<br />

The last adjusted temperature level will be chos<strong>en</strong>.<br />

4.3.3 Accompl<strong>is</strong>hm<strong>en</strong>t of <strong>the</strong> ear rinsing<br />

Take handle hold nozzle in work item and activate trigger accompl<strong>is</strong>h ear rinsing<br />

ATT<strong>ENT</strong>ION:<br />

Make sure <strong>the</strong> water supply system <strong>is</strong> on and <strong>the</strong> water supply secured !<br />

16

4.0 Operation<br />

4.4 Thermal nystagmus stimulation, Vario<strong>the</strong>rm<br />

!<br />

!<br />

The integrated Vario<strong>the</strong>rm features separate operating instructions.<br />

Please note:<br />

Read <strong>the</strong>se separate operating instructions att<strong>en</strong>tively and follow <strong>the</strong> stated notes for your safety to guarantee ideal<br />

and safe use of all functions!<br />

ATT<strong>ENT</strong>ION:<br />

Make sure that <strong>the</strong> water supply system <strong>is</strong> on and <strong>the</strong> water supply secured!<br />

■ If you switch on <strong>the</strong> appliance a segm<strong>en</strong>t-test will be carried out. For a mom<strong>en</strong>t all LEDs will be activated.<br />

In th<strong>is</strong> time please check <strong>the</strong> function of <strong>the</strong> LEDs optically.<br />

■Before <strong>the</strong> caloric measurem<strong>en</strong>ts you have to check <strong>the</strong> water pressure at <strong>the</strong> manometer in <strong>the</strong> service room.<br />

It has to be a desired pressure of 2 bar. Beware of overpressure!<br />

The ear irrigation hose may only be used with an ear irrigation bowl which has an integrated sieve! It <strong>is</strong> not<br />

suitable for secretion suction.<br />

adjustable<br />

temperature and time<br />

handle<br />

<strong>the</strong>rmal nystagmus<br />

stimulation<br />

on- / off switch<br />

nystagmus glasses<br />

connection<br />

nystagmus glasses<br />

4.3.1 Ear irrigation module compressed air REF 530.2070.0<br />

!<br />

The suction channel for <strong>the</strong> <strong>ATMOS</strong> ear irrigation bowl may only be used for suction during ear irrigation or stimulation.<br />

Only <strong>the</strong> ear irrigation bowl with integrated sieve (hole diameter 1 mm at a maximum) may be used. The<br />

suction channel <strong>is</strong> not suitable for any o<strong>the</strong>r suction procedure in <strong>the</strong> medical field! The liquid pump <strong>is</strong> not suitable<br />

for sucking off bigger particles like, for example, cerum<strong>en</strong>, etc. Therefore, suction may only be performed with<br />

bowl and sieve.<br />

Greasy and pasty substances can be sucked off but only limited. It <strong>is</strong> recomm<strong>en</strong>ded to clean <strong>the</strong> bowl after each<br />

suction procedure and to rinse it with water (d<strong>is</strong>infectant) in order to prev<strong>en</strong>t <strong>the</strong> pump valves from jamming.<br />

Take out <strong>the</strong> suction nozzle with <strong>the</strong> ear irrigation bowl from <strong>the</strong> susp<strong>en</strong>sion, <strong>the</strong> suction system switches on automatically.<br />

Th<strong>en</strong> apply <strong>the</strong> bowl with <strong>the</strong> lateral cut-out below <strong>the</strong> ear which needs to be irrigated and start irrigation.<br />

Wh<strong>en</strong> <strong>the</strong> suction nozzle <strong>is</strong> put back to <strong>the</strong> susp<strong>en</strong>sion, <strong>the</strong> suction system stops automatically.<br />

Att<strong>en</strong>tion: Please use <strong>the</strong> suction system with ear irrigation bowl only.<br />

4.4.1 Activation of <strong>the</strong> Vario<strong>the</strong>rm<br />

Take handle from holder. By <strong>the</strong> installed light barrier <strong>the</strong> Vario<strong>the</strong>rm activates automatically.<br />

The last actived temperature level will be chos<strong>en</strong>.<br />

4.4.2 Accompl<strong>is</strong>hm<strong>en</strong>t of <strong>the</strong> <strong>the</strong>rmal nystagmus stimulation<br />

Take handle choose temperature and adjust if necessary (q.v. 4.4.4) if required set time <br />

press (flashing approx. 10 sec.) if <strong>the</strong> Vario<strong>the</strong>rm <strong>is</strong> ready for use you hear a beep hold nozzle in work item and<br />

activate trigger accompl<strong>is</strong>h nystagmus stimulation after <strong>the</strong> lapse of time you here a beep again<br />

4.4.3 Time setting (1-99 sec.)<br />

Take handle.<br />

Press and hold . Set <strong>the</strong> desired stimulation time with .<br />

At <strong>the</strong> next selection of <strong>the</strong> particular temperature, <strong>the</strong> time setting<br />

from <strong>the</strong> previous time will automatically be assumed.<br />

3<br />

Casually check <strong>the</strong> time setting of <strong>the</strong> timer.<br />

1 2<br />

4 5 6<br />

17

4.0 Operation<br />

4.4.4 Temperature setting<br />

You can apply <strong>the</strong> Vario<strong>the</strong>rm at temperatures from 20°C to 47°C.<br />

The minimum temperature <strong>is</strong> giv<strong>en</strong> from <strong>the</strong> temperature of <strong>the</strong> tap water.<br />

3<br />

setting at 37°C:<br />

Press for <strong>the</strong> temperature.<br />

warm stimulus (38 - 47°C):<br />

Take handle.<br />

Press and hold . Set <strong>the</strong> desired temperature with . Release .<br />

At <strong>the</strong> next selection of <strong>the</strong> key <strong>the</strong> presetted temperature will be assumed.<br />

cold stimulus (20 - 36°C):<br />

Take handle.<br />

Press and hold . Set <strong>the</strong> desired temperature with . Release .<br />

At <strong>the</strong> next selection of <strong>the</strong> key <strong>the</strong> presetted temperature will be assumed.<br />

1 2<br />

4 5 6<br />

4.4.5 Information about <strong>the</strong> service d<strong>is</strong>play of <strong>the</strong> <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> up from software version V 1.2<br />

The <strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong> <strong>workstation</strong> has<br />

a service d<strong>is</strong>play on <strong>the</strong> front panel.<br />

The d<strong>is</strong>play cons<strong>is</strong>ts of a red and a yellow LED.<br />

red LED<br />

yellow LED<br />

18<br />

After switch on of <strong>the</strong> module a test cycle starts to check <strong>the</strong> electronics. The following indications are possible:<br />

Red LED Yellow LED Beep Remarks<br />

Immediately after switch on <strong>the</strong> LED test starts.<br />

Both LEDs fl ash up<br />

Switch on fl ash up fl ash up yes simultaneously during switch<br />

on (duration: 500 ms).<br />

Afterwards a functional and aggregate test follows where 6 fl ashlight signals appear<br />

(duration: fl ash up/stop: 500 ms/500 ms).<br />

Operating time pressure pump fi rst flash up no o.k.<br />

Operating time suction pump second fl ash up no o.k.<br />

Operating time suction pump 2 third fl ash up no o.k.<br />

Operating time hose pump fourth fl ash up no o.k.<br />

Operating time drainage pump fi fth flash up no o.k.<br />

Annual maint<strong>en</strong>ance sixth fl ash up no o.k.<br />

Battery voltage sev<strong>en</strong>th fl ash up no o.k.<br />

Maint<strong>en</strong>ance <strong>is</strong> required:<br />

Operating time pressure pump fi rst flash up yes critical operating time<br />

Operating time suction pump second fl ash up yes critical operating time<br />

Operating time suction pump 2 third fl ash up yes critical operating time<br />

Operating time hose pump fourth fl ash up yes critical operating time<br />

Operating time drainage pump fi fth flash up yes critical operating time<br />

Annual maint<strong>en</strong>ance sixth fl ash up yes annual maint<strong>en</strong>ance <strong>is</strong> due<br />

Battery voltage sev<strong>en</strong>th fl ash up yes low battery voltage<br />

In <strong>the</strong> case any maint<strong>en</strong>ance <strong>is</strong> required, please contact your local <strong>ATMOS</strong> service partner.

4.0 Operation<br />

4.5 Ear rinsing module 37 °C basic<br />

Wh<strong>en</strong> switching on <strong>the</strong> unit, <strong>the</strong> quivers for <strong>the</strong> ear rinsing system will be<br />

activated and heated up to 37°C.<br />

Only use antibacterial rinsing fluid for rinsing <strong>the</strong> auditory channel.<br />

The temperature of <strong>the</strong> rinsing fl uid has to be checked with a <strong>the</strong>rmometer before using.<br />

It must be 37°C ± 2°C, o<strong>the</strong>rw<strong>is</strong>e <strong>the</strong> pati<strong>en</strong>t may feel dizzy or can collapse.<br />

The vacuum gauge may indicate max. -0.4 bar at closed op<strong>en</strong>ing on . It has to be checked before each<br />

application on <strong>the</strong> pati<strong>en</strong>t.<br />

To avoid awkward and loud side-air-tones, <strong>the</strong> application part `rinsing peak` has to be held close to <strong>the</strong><br />

acoustic meatus.<br />

Rinsing fl uid, which <strong>is</strong> no longer in use, has to be d<strong>is</strong>posed at <strong>the</strong> <strong>en</strong>d of <strong>the</strong> practice business.<br />

<br />

<br />

<br />

<br />

<br />

<br />

• The rinsing bottle will be fi lled with warm rinsing fl uid<br />

(37°C ± 2°C). The rinsing lid with <strong>the</strong> hose will be<br />

screwed onto <strong>the</strong> bottle and slightly tight<strong>en</strong>ed.<br />

• Via <strong>the</strong>rmometer <strong>the</strong> temperature can be monitored.<br />

• The t<strong>en</strong>der peak will be attached onto <strong>the</strong> cylindric<br />

attempt at <strong>the</strong> rinsing lid as far as it will go<br />

• Connect <strong>the</strong> suction hose with <strong>the</strong> vacuum port of <strong>the</strong><br />

ear rinsing system. Set suction system on maximum<br />

vacuum.<br />

• Now <strong>the</strong> ear rinsing system with <strong>the</strong> t<strong>en</strong>der peak <strong>is</strong><br />

putted into <strong>the</strong> acoustic meatus. Keep <strong>the</strong> side-air op<strong>en</strong>ing<br />

closed with your fi nger. As long as <strong>the</strong> side-air op<strong>en</strong>ing<br />

<strong>is</strong> op<strong>en</strong>, it will be rinsed.<br />

Ear rinsing system<br />

t<strong>en</strong>der peak for rinsing<br />

side-air aperture<br />

vacuum port on system<br />

rinsing lid (complete)<br />

rinsing bottle<br />

safety aperture<br />

19

4.0 Operation<br />

4.6 Compressed-air system<br />

medication sprayer<br />

(compressed-air)<br />

handle for compressed-air<br />

■ Make sure equipm<strong>en</strong>t and hoses are connected tightly to build up a suffici<strong>en</strong>t pressure.<br />

■ If you use politzer olives, control pressure in acc. with <strong>the</strong> appliance.<br />

4.6.1 Activation<br />

For activation of <strong>the</strong> compressed-air system you have following alternatives:<br />

A)<br />

If you have a foot switch connected:<br />

Take handle from holder. Afterwards push and hold <strong>the</strong> foot switch for activation.<br />

Wh<strong>en</strong> releasing, <strong>the</strong> compressed-air system deactivates again.<br />

B)<br />

If you do not have a foot switch connected:<br />

Take handle from holder. By <strong>the</strong> installed light barrier <strong>the</strong> compressed-air system activates automatically.<br />

4.6.2 Adapt / deposit sprayer<br />

Adapt:<br />

Deposit:<br />

2<br />

1<br />

3<br />

Stick () handle onto <strong>the</strong><br />

medication bottle.<br />

Let snap, th<strong>en</strong> lift medication<br />

bottle with handle out<br />

of <strong>the</strong> attachm<strong>en</strong>t ().<br />

By pulling <strong>the</strong> trigger,<br />

compressed-air will be<br />

applied into <strong>the</strong> sprayer<br />

().<br />

1<br />

2<br />

Adapt medication bottle top<br />

down into in <strong>the</strong> attachm<strong>en</strong>t.<br />

Press activator () and pull<br />

handle () backwards.<br />

■ Handle carefully wh<strong>en</strong> using a sprayer to avoid injuries.<br />

■ Before using <strong>the</strong> sprayer bottle, check <strong>the</strong> def<strong>en</strong>sibility of <strong>the</strong> included medications.<br />

■ Clean all parts of <strong>the</strong> sprayer regularly ! Therefore find advices in section 5.0 `Cleaning` !<br />

20

4.0 Operation<br />

4.6.3 Ear irrigation module compressed air system (REF 530.2080.0)<br />

2 In order to start <strong>the</strong> ear irrigation, please close <strong>the</strong> v<strong>en</strong>t valve () and<br />

press <strong>the</strong> adjusting lever (). You stop ear irrigation in releasing <strong>the</strong><br />

adjusting lever () and <strong>the</strong> v<strong>en</strong>t valve ().<br />

Irrigation stops immediately!<br />

1<br />

!<br />

The glass vials have to be checked for intactness prior to every<br />

use (cracks, chippings on <strong>the</strong> winding, etc.). Brok<strong>en</strong> glass vials<br />

may not be used for ear irrigation.<br />

adjusting lever<br />

v<strong>en</strong>t valve<br />

4.7 LED-Light system<br />

on/off LED<br />

LED-port (for light source or head light)<br />

LED-port (for light source or head light)<br />

21

4.0 Operation<br />

4.8 Instrum<strong>en</strong>t heating<br />

4.8.1 Mirror quick heating<br />

A<br />

Press A.<br />

The mirror quick heating <strong>is</strong> activated for 10 sec.<br />

!<br />

Fire hazard !<br />

Before using <strong>the</strong> mirror on a pati<strong>en</strong>t, check its temperatur (on <strong>the</strong> back of your hand o.s.).<br />

Only heat up d<strong>is</strong>infected instrum<strong>en</strong>ts !<br />

4.8.2 Heating module for instrum<strong>en</strong>t tray<br />

Wh<strong>en</strong> switching on <strong>the</strong> unit, <strong>the</strong> heating system for <strong>the</strong> instrum<strong>en</strong>t tray will be activated and heated up to 37°C.<br />

Put <strong>the</strong> instrum<strong>en</strong>ts you want to heat down on <strong>the</strong> metal tray.<br />

Trays are meant for <strong>the</strong> use with unsterile instrum<strong>en</strong>ts only.<br />

4.8.3 Instrum<strong>en</strong>t heating with <strong>the</strong> ear rinsing system 37°C basic<br />

Wh<strong>en</strong> switching on <strong>the</strong> unit, <strong>the</strong> heating system for <strong>the</strong> instrum<strong>en</strong>t tray will also be activated and heated up to 37°C.<br />

Clean and d<strong>is</strong>infect <strong>the</strong> quivers regularly! Advices in section 5.0 `Cleaning`.<br />

22

4.0 Operation<br />

4.9 Clipboard <strong>en</strong>doscopy<br />

Integration of 3-channel <strong>en</strong>doscope managem<strong>en</strong>t for rigid and<br />

flexible <strong>en</strong>doscopes.<br />

4.9.1 Option LED Light Cube<br />

The LED Light Cube <strong>is</strong> automatically activated wh<strong>en</strong> switching<br />

on <strong>the</strong> unit.<br />

With a simple rotary motion <strong>the</strong> adapters are screwed in up to<br />

<strong>the</strong> stop position and fixed in <strong>the</strong> Clipboard. The light conductors<br />

can be plugged in <strong>the</strong> connection. The light channel <strong>is</strong><br />

automatically activated wh<strong>en</strong> <strong>the</strong> light conductor <strong>is</strong> removed<br />

from <strong>the</strong> support. Manual on and off switching of <strong>the</strong> light<br />

channels by means of <strong>the</strong> keypad <strong>is</strong> also possible.<br />

Screwing in <strong>the</strong> adapter<br />

4.9.2 Option <strong>en</strong>doscope managem<strong>en</strong>t (heated)<br />

Endoscope heating <strong>is</strong> activated automatically wh<strong>en</strong> <strong>the</strong> unit <strong>is</strong><br />

switched on. The quivers are heated to 41°C.<br />

Clipboard with connected light<br />

conductors<br />

Operating <strong>the</strong> keypad<br />

4.9.3 Hook for <strong>the</strong> headlamp with automatic<br />

switching<br />

Headlight can easily be removed and put back during <strong>the</strong><br />

examination. Connect <strong>the</strong> headlamp to <strong>the</strong> clipboard as<br />

described in chapter 4.9.1. Hereto please use <strong>the</strong> right light<br />

channel. <strong>Th<strong>is</strong></strong> light channel <strong>is</strong> th<strong>en</strong> automatically activated if<br />

<strong>the</strong> headlight <strong>is</strong> removed from <strong>the</strong> hook.<br />

In order to guarantee error-free operation, please seal <strong>the</strong><br />

light barrier of <strong>the</strong> right light channel with <strong>the</strong> provided blind<br />

plug.<br />

Clipboard with connected headlight<br />

23

5.0 Cleaning<br />

5.1 G<strong>en</strong>eral information on cleaning and d<strong>is</strong>infection<br />

Before cleaning<br />

Medical devices must always offer a maximum in safety and function.<br />

Therefore we recomm<strong>en</strong>d:<br />

Prior to each application:<br />

picture<br />

back<br />

if<br />

necessary<br />

The described measures to clean and to d<strong>is</strong>infect<br />

don`t exchange <strong>the</strong> instructions giv<strong>en</strong> in <strong>the</strong> particular<br />

company!<br />

• In <strong>the</strong> following sub-chapter `recomm<strong>en</strong>ded d<strong>is</strong>infectants` all<br />

m<strong>en</strong>tioned surface and instrum<strong>en</strong>t d<strong>is</strong>intectants are qualifi ed<br />

for d<strong>is</strong>infection.<br />

• Please take care that all surfaces are dry wiped.<br />

Use a single-use cloth to absorb any liquid.<br />

• In case that any d<strong>is</strong>infectant <strong>is</strong> spilled, please take care to<br />

dry wipe <strong>the</strong> surface immediately in order that no liquid may<br />

p<strong>en</strong>etrate gaps and edges.<br />

5.1.1 Cleaning <strong>the</strong> unit surface<br />

• The unit’s surfaces are coated with a special textured<br />

lacquer that fulfi lls <strong>the</strong> requirem<strong>en</strong>ts for <strong>workstation</strong><br />

hygi<strong>en</strong>e.<br />

• Wipe <strong>the</strong> unit surface with a cloth, mo<strong>is</strong>t<strong>en</strong>ed with a<br />

cleaning or d<strong>is</strong>infecting solution.<br />

• You may also use d<strong>is</strong>infectant sprays or d<strong>is</strong>infectant<br />

t<strong>is</strong>sues for cleaning and d<strong>is</strong>infection.<br />

Long-term use of d<strong>is</strong>infectants with alcohol might<br />

affect <strong>the</strong> flexibility and transpar<strong>en</strong>cy of <strong>the</strong><br />

protective covers.<br />

Always observe <strong>the</strong> conc<strong>en</strong>tration specifi cations<br />

and instructions by <strong>the</strong> respective manufacturer<br />

• Do not use<br />

• D<strong>is</strong>infectants containing conc<strong>en</strong>trated organic<br />

or anorganic acids or bases, since <strong>the</strong>se may cause<br />

corrosion damages.<br />

• D<strong>is</strong>infectants containing chloramides, ph<strong>en</strong>ol derivatives<br />

or anionic t<strong>en</strong>sides, since <strong>the</strong>se may cause<br />

stress cracks in <strong>the</strong> material used for <strong>the</strong> housing of<br />

<strong>the</strong> unit.<br />

■ All application parts, which are exposed to direct contact with <strong>the</strong> pati<strong>en</strong>t during <strong>the</strong> treatm<strong>en</strong>t, have to be exchanged,<br />

cleaned or d<strong>is</strong>infected immediately for hygi<strong>en</strong>ic reasons.<br />

■ Only put cleaned instrum<strong>en</strong>ts on <strong>the</strong> deposits!<br />

■ Clean and d<strong>is</strong>infect <strong>the</strong> instrum<strong>en</strong>t deposits regularly!<br />

24

5.0 Cleaning<br />

5.1.2 Collection jar (without autom.<br />

collection jar draining),<br />

bacterial filter<br />

and suction hose<br />

• At <strong>the</strong> <strong>en</strong>d of every working-day, <strong>the</strong> following parts must be<br />

cleaned and d<strong>is</strong>infected:<br />

• Collection jar with lid system and bacterial filter:<br />

• Pull all hose connections from <strong>the</strong> lid system and<br />

carefully remove <strong>the</strong> jar from <strong>the</strong> jar holder<br />

in order to prev<strong>en</strong>t a contamination of <strong>the</strong> area<br />

around <strong>the</strong> unit (e.g. drops).<br />

Properly d<strong>is</strong>pose <strong>the</strong> sucked material.<br />

•Take <strong>the</strong> collection jar at <strong>the</strong> lid system, op<strong>en</strong><br />

<strong>the</strong> bacterial filter cover by turning it anti-clockw<strong>is</strong>e<br />

and remove <strong>the</strong> filter plate. Thoroughly rinse all<br />

parts under running water. You may, of course,<br />

add a cleanser or deterg<strong>en</strong>t.<br />

• Suction system and hose attachm<strong>en</strong>t:<br />

• After every use, rinse out <strong>the</strong> suction system by<br />

drawing in a small amount of irrigating fluid (e.g.<br />

<strong>ATMOS</strong> Special Cleanser 080.0005.0).<br />

Keeps <strong>the</strong> hoses from becoming sticky or clogged.<br />

Suction capacity <strong>is</strong> limited by <strong>the</strong> 1.25 l collection jar.<br />

Therefore, do not use more than 1 l rinsing liquid and<br />

subsequ<strong>en</strong>tly evacuate <strong>the</strong> jar.<br />

Replace <strong>the</strong> filter.<br />

25

5.0 Cleaning<br />

5.1.3 Medication sprayers<br />

!<br />

• The sprayer tube must be exchanged after each pati<strong>en</strong>t.<br />

• D<strong>is</strong>mount <strong>the</strong> medication sprayer and thoroughly rinse<br />

all parts under running water. You may, of course, add a<br />

cleanser or deterg<strong>en</strong>t.<br />

• Use water to thoroughly rinse all residues of <strong>the</strong>se<br />

substances.<br />

<br />

Make sure that <strong>the</strong> air op<strong>en</strong>ing <strong>is</strong> not closed!<br />

• D<strong>is</strong>infect all compon<strong>en</strong>ts with <strong>the</strong> d<strong>is</strong>infectants m<strong>en</strong>tioned<br />

in 5.2.<br />

<br />

<br />

Wh<strong>en</strong> fixing <strong>the</strong> twin tube nozzle again, make sure that<br />

<strong>the</strong> mark (0,X or milling area) on <strong>the</strong> nozzle shows<br />

upwards!<br />

Sprayer tubes are available as spare parts<br />

at <strong>ATMOS</strong>.<br />

5.1.4 Instrum<strong>en</strong>t trays<br />

• Before d<strong>is</strong>infection, thoroughly rinse <strong>the</strong> trays under running<br />

water. You may, of course, add a cleanser (deterg<strong>en</strong>t) or<br />

surface d<strong>is</strong>infectant.<br />

• Use water to thoroughly rinse all residues of <strong>the</strong>se<br />

substances.<br />

• D<strong>is</strong>infect with one of <strong>the</strong> d<strong>is</strong>infectants m<strong>en</strong>tioned in 5.3<br />

afterwards.<br />

Trays made of anodized aluminium and melamine cannot be<br />

sterilized!<br />

5.1.5 Endoscope quivers<br />

• The metal quivers of <strong>the</strong> <strong>en</strong>doscope holder exclusively<br />

serve for keeping <strong>the</strong> berore cleaned and d<strong>is</strong>infected <strong>en</strong>doscopes.<br />

Clean quivers daily and d<strong>is</strong>infect. Thereto, <strong>the</strong> sealing<br />

plug at <strong>the</strong> lower <strong>en</strong>d should be tak<strong>en</strong> off.<br />

5.1.6 Ear rinsing bowl<br />

• The ear irrigation bowl <strong>is</strong> not autoclavable!<br />

Cleaning and d<strong>is</strong>infection (also machine cleaning) up to<br />

93°C.<br />

26

5.0 Cleaning<br />

5.2 Recomm<strong>en</strong>ded instrum<strong>en</strong>t d<strong>is</strong>infectants<br />

Manual d<strong>is</strong>infection of instrum<strong>en</strong>ts<br />

D<strong>is</strong>infectant Ingredi<strong>en</strong>ts (in 100 g) Manufacturer<br />

Korsolex basic Glutaral 15.2 g Bode Chemie, Hamburg<br />

(Application conc<strong>en</strong>trate) (ethyl<strong>en</strong>e-dioxy)dimethanol 19.7 g<br />

t<strong>en</strong>sides, salts, corrosion inhibitors<br />

Korsolex extra (ethyl<strong>en</strong>e-dioxy)dimethanol 15.3 g Bode Chemie, Hamburg<br />

(Application conc<strong>en</strong>trate) Glutaral 7.5 g<br />

B<strong>en</strong>zyl-C12-C18-alkyldimethyl-<br />

1.0 g<br />

ammonium chloride, t<strong>en</strong>sides,<br />

didecylmethylammonium chloride<br />

corrosion inhibitors<br />

neod<strong>is</strong>her Septo MED dodecylb<strong>is</strong>propyl<strong>en</strong>triamine 9.2 g Dr. Weigert, Hamburg<br />

(Application conc<strong>en</strong>trate) didecyl dimethyl ammonium chloride 13.0 g<br />

non-ionic t<strong>en</strong>sides, fragrances<br />

Sekusept aktiv sodiumpercarbonate, phosphonates Ecolab, Düsseldorf<br />

(Application conc<strong>en</strong>trate) non-ionic t<strong>en</strong>sides<br />

Gigasept FF new succinic acid dialdehyde 11.0 g Schülke & Mayr, Norderstedt<br />

(Application conc<strong>en</strong>trate) dimethoxy tetrahydrofurane 3.0 g<br />

corrosion inhibitors<br />

Machine d<strong>is</strong>infection of instrum<strong>en</strong>ts<br />

D<strong>is</strong>moclean 24 Vario t<strong>en</strong>sides, micro-<strong>en</strong>capsulated <strong>en</strong>zymes Bode Chemie, Hamburg<br />

(Application conc<strong>en</strong>trate) corrosion inhibitors<br />

complexing ag<strong>en</strong>t<br />

D<strong>is</strong>moclean twin basic/twin zyme<br />

D<strong>is</strong>moclean twin basic<br />

D<strong>is</strong>moclean twin zyme<br />

alkali d<strong>is</strong>p<strong>en</strong>ser, complexing ag<strong>en</strong>t<br />

corrosion inhibitors<br />

surface active materials, <strong>en</strong>zymes,<br />

stabil<strong>is</strong>ers, corrosion inhibitors<br />

Bode Chemie, Hamburg<br />

neod<strong>is</strong>her MediClean forte non-ionic t<strong>en</strong>sides

Cleaning and d<strong>is</strong>infection plan<br />

6.0 Hygi<strong>en</strong>e plan<br />

<strong>ATMOS</strong> S <strong>61</strong> <strong>Servant</strong><br />

What<br />

How<br />

Wh<strong>en</strong><br />

Who<br />

Reusable parts<br />

C<br />

Cleaning<br />

D S<br />

D<strong>is</strong>infection Steril<strong>is</strong>ation<br />

Recomm<strong>en</strong>dations<br />

After each<br />

procedure<br />

Daily<br />

Weekly<br />

Monthly<br />

Qualified and trained<br />

staff who are familiar<br />

with reprocessing.<br />

(Please fill in <strong>the</strong><br />

responsible person<br />

-> use a water-based<br />

overhead marker)<br />

Secretion can<strong>is</strong>ter<br />

Hose connection (nozzle) X X 2,4,5 Cleaning and d<strong>is</strong>infection (automatic or manual) X<br />

Suction lid X X 2,4,5 Cleaning and d<strong>is</strong>infection (automatic or manual) X<br />

Gasket X X 2,4,5 Cleaning and d<strong>is</strong>infection (automatic or manual) X<br />

Bacterial fi lter Daily exchange or wh<strong>en</strong> fi lter <strong>is</strong> blocked X<br />

Splash protection X X 2,4,5 Cleaning and d<strong>is</strong>infection (automatic or manual) X<br />

Float ball X X Cleaning and d<strong>is</strong>infection (automatic or manual) X<br />

Suction hose in <strong>the</strong><br />

can<strong>is</strong>ter<br />

X X 2,4,5 Cleaning and d<strong>is</strong>infection (automatic or manual) X<br />

Secretion collection<br />

Empty wh<strong>en</strong> <strong>the</strong> can<strong>is</strong>ter <strong>is</strong> full; at least daily<br />

X X<br />

can<strong>is</strong>ter<br />

Cleaning and d<strong>is</strong>infection (automatic or manual)<br />

X<br />

D<strong>is</strong>posable can<strong>is</strong>ter<br />

system<br />

Exchange and d<strong>is</strong>posal of full can<strong>is</strong>ter<br />

X<br />

Hose irrigation system<br />

Suction nozzle<br />

for hose irrigation<br />

Silicone attachm<strong>en</strong>t piece<br />

Suction nipple<br />

Secretion suction hose<br />

Storage container for<br />

hose irrigation system<br />

X X 3 Wipe cleaning and d<strong>is</strong>infection X<br />

X X 2,4,5,6 Cleaning and d<strong>is</strong>infection (automatic or manual) X<br />

Exchange of <strong>the</strong> Silicone attachm<strong>en</strong>t<br />

X Manual cleaning after each pati<strong>en</strong>t X<br />

X 2,4,5,6 Manual or automatic cleaning and d<strong>is</strong>infection X<br />

Rinse <strong>the</strong> secretion hose with <strong>the</strong> hose irrigation<br />

X<br />

X<br />

system after each procedure;<br />

X 2,4,5,6 Exchange or d<strong>is</strong>infection of <strong>the</strong> hose X<br />

Cleaning with a brush; Manual or automatic cleaning and<br />

X X 2,4,5,6 X<br />

d<strong>is</strong>infection<br />

Ear irrigation / Thermal nystagmus stimulation<br />

Ear irrigation bowl X X 2,4,5 Manual or automatic cleaning and d<strong>is</strong>infection X<br />

Handle X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Jet connection X X 2,4,5,6 Manual or automatic cleaning and d<strong>is</strong>infection X<br />

Splash protection X X 2,4,5 Cleaning and d<strong>is</strong>infection (automatic or manual) X<br />

Hose tip (d<strong>is</strong>posable) Exchange after each application X<br />

Rinsing attachm<strong>en</strong>t X X 2,4,5 Manual or automatic cleaning and d<strong>is</strong>infection X<br />

Hygi<strong>en</strong>e fi lter See operating instructions for hygi<strong>en</strong>e fi lter X<br />

Rinsing lid with rinsing<br />

hose<br />

X X 2,4,5 Manual or automatic cleaning and d<strong>is</strong>infection X<br />

Rinsing bottle X X 2,4,5,6 Cleaning and d<strong>is</strong>infection; cleaning in <strong>the</strong> d<strong>is</strong>hwasher<br />

with <strong>the</strong> glass care programme<br />

Medication nebul<strong>is</strong>ation / Politzer<br />

Handle for<br />

X X Manual cleaning and d<strong>is</strong>infection X<br />

compressed air<br />

X Cleaning after each application X<br />

Sprayer jet<br />

X 2,4,5,6 Manual or automatic cleaning and d<strong>is</strong>infection X<br />

Sprayer head X X 2,4,5 Multiple rinsing of <strong>the</strong> sprayer head with water X<br />

Hose at sprayer head X X<br />

Weekly exchange of <strong>the</strong> hose or wh<strong>en</strong> changing <strong>the</strong><br />

medication<br />

Sprayer bottle X X 2,4,5,6 Cleaning in a cleaning and d<strong>is</strong>infection device; weekly or<br />

wh<strong>en</strong> changing <strong>the</strong> medication<br />

Politzer olive X X 2,4,5,6 Exchange after each application.<br />

Cleaning and d<strong>is</strong>infection<br />

Politzer connection X X 2,4,5,6 Exchange after each application.<br />

Cleaning and d<strong>is</strong>infection<br />

Endoscope managem<strong>en</strong>t<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

Plastic quiver X X 2,4,5 Cleaning with a brush; d<strong>is</strong>infection X<br />

Metal quiver X X 2,4,5,6 Cleaning with a brush; d<strong>is</strong>infection (automatic or manual) X<br />

Fixation adapter for<br />

plastic quiver<br />

X X 2,4,5 Manual or automatic cleaning and d<strong>is</strong>infection X<br />

Protective sleeve (tefl on<br />

elem<strong>en</strong>t for metal quiver)<br />

X X 2,4,5 Manual or automatic cleaning and d<strong>is</strong>infection X

What<br />

How<br />

Wh<strong>en</strong><br />

Who<br />

6.0 Hygi<strong>en</strong>eplan C<br />

Reusable parts<br />

Cleaning<br />

D S<br />

D<strong>is</strong>infection Steril<strong>is</strong>ation<br />

Recomm<strong>en</strong>dations<br />

After each<br />

procedure<br />

Daily<br />

Weekly<br />

Monthly<br />

Qualified and trained<br />

staff who are familiar<br />

with reprocessing.<br />

(Please fill in <strong>the</strong> responsible<br />

person -><br />

use a water-based<br />

overhead marker)<br />

Instrum<strong>en</strong>t managem<strong>en</strong>t<br />

<strong>ENT</strong> instrum<strong>en</strong>ts X X 2,4,5 X<br />

Immerse instrum<strong>en</strong>ts into solution immediately after use,<br />

complete wetting <strong>is</strong> required, air must be removed from<br />

any cavities, after <strong>the</strong> contact time instrum<strong>en</strong>ts must be<br />

rinsed with water, have to be dried and steril<strong>is</strong>ed afterwards.<br />

X<br />

Please also observe <strong>the</strong> <strong>ATMOS</strong> operating<br />

instructions for <strong>ENT</strong> instrum<strong>en</strong>ts.<br />

Instrum<strong>en</strong>t bowl X X 2,4,5 Manual or automatic cleaning and d<strong>is</strong>infection X<br />

Instrum<strong>en</strong>t bowl with<br />

cover<br />

V<strong>is</strong>ual<strong>is</strong>ation<br />

X X 2,4,5 Cleaning with a brush; afterwards d<strong>is</strong>infection<br />

Manual or automatic cleaning and d<strong>is</strong>infection<br />

X<br />

<strong>ATMOS</strong> Cam 21 / 31 X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

<strong>ATMOS</strong> Strobo 21 LED X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Flexible scope X X 1) X 1) Immediate pre-cleaning after <strong>the</strong> procedure X<br />

Rigid scope X X 1) X 1) Immediate pre-cleaning after <strong>the</strong> procedure X<br />

Laryngoscope X X 1) X 1) Immediate pre-cleaning after <strong>the</strong> procedure X<br />

Light conductor X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Light source X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Microscope X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Headlight X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Radiofrequ<strong>en</strong>cy surgery<br />

<strong>ATMOS</strong> RS 221<br />

X X<br />

(surface)<br />

3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Ergonomic plastic handles X X 1,2,4,5 X 1) Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Bipolar tweezers X X 1,2,4,5 X 1) Immediate pre-cleaning after <strong>the</strong> procedure<br />

X<br />

cleaning and d<strong>is</strong>infection (automatic or manual);<br />

Bipolar electrode X X 1,2,4,5 X 1) use of <strong>en</strong>zymatic deterg<strong>en</strong>ts<br />

X<br />

Bipolar electrode cable X X 1,2,4,5 X 1) Immediate pre-cleaning after <strong>the</strong> procedure<br />

X<br />

cleaning and d<strong>is</strong>infection (automatic or manual);<br />

Neutral electrode X X 1,2,4,5 X 1) use of <strong>en</strong>zymatic deterg<strong>en</strong>ts<br />

X<br />

Neutral electrode cable X X 1,2,4,5 X 1) Immediate pre-cleaning after <strong>the</strong> procedure<br />

X<br />

cleaning and d<strong>is</strong>infection (automatic or manual);<br />

<strong>ENT</strong> electrodes X X 1,2,4,5 X 1) use of <strong>en</strong>zymatic deterg<strong>en</strong>ts<br />

X<br />

Surfaces<br />

Housing X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Roller shutter X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

System frame X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Drawers X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Writing surface X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Instrum<strong>en</strong>t deposit X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Mirror pre-heater X X 3 Wipe cleaning and wipe d<strong>is</strong>infection X<br />

Tongue patches and<br />

swab d<strong>is</strong>p<strong>en</strong>ser<br />

X X 3 Wipe cleaning and wipe d<strong>is</strong>infection,<br />

every day or wh<strong>en</strong> refi lling<br />

Waste d<strong>is</strong>posal X X 3 Wipe cleaning and wipe d<strong>is</strong>infection,<br />

every day or wh<strong>en</strong> emptying <strong>the</strong> container<br />

Instrum<strong>en</strong>t tray X X 3 Wipe cleaning and wipe d<strong>is</strong>infection, daily wh<strong>en</strong> replacing<br />

with new instrum<strong>en</strong>ts<br />

X<br />

X<br />

X<br />

Recomm<strong>en</strong>ded d<strong>is</strong>infectants<br />

3) Surface d<strong>is</strong>infection<br />

for coated surfaces:<br />

O<strong>the</strong>r surfaces:<br />

Gre<strong>en</strong> & Clean SK (<strong>ATMOS</strong>)<br />

D<strong>is</strong>mozon ® pur (Bode Chemie)<br />

Kohrsolin ® FF (Bode Chemie)<br />

Perform ® (Schülke & Mayr)<br />

Terralin ® Protect (Schülke & Mayr)<br />

D<strong>is</strong>mozon ® pur (Bode Chemie)<br />

Kohrsolin ® FF (Bode Chemie)<br />

Bacillocid ® rasant (Bode Chemie)<br />

Mikrobac ® forte (Bode Chemie)<br />

Perform ® (Schülke & Mayr)<br />

Terralin ® Protect (Schülke & Mayr)<br />

Surface d<strong>is</strong>infection FD 312 (Dürr D<strong>en</strong>tal)<br />

Quick d<strong>is</strong>infection B 30 (Orochemie)<br />

4) 5) Instrum<strong>en</strong>ts - manual d<strong>is</strong>infection: Instrum<strong>en</strong>ts - automatic d<strong>is</strong>infection:<br />

Korsolex ® AF (Bode Chemie)<br />

D<strong>is</strong>moclean ® 21 clean (Bode Chemie)<br />

Korsolex ® basic (Bode Chemie) D<strong>is</strong>moclean ® 24 Vario (Bode Chemie)<br />

Korsolex ® plus (Bode Chemie) D<strong>is</strong>moclean ® 28 alka one (Bode Chemie)<br />

Korsolex ® extra (Bode Chemie) D<strong>is</strong>moclean ® twin basic/twin zyme (Bode Chemie)<br />

neod<strong>is</strong>her ® Septo MED (Dr. Weigert) neod<strong>is</strong>her ® FA (Dr. Weigert)<br />

neod<strong>is</strong>her ® Septo 3000 (Dr. Weigert) neod<strong>is</strong>her ® FA forte (Dr. Weigert)<br />

Sekusept ® PLUS (Ecolab)<br />

neod<strong>is</strong>her ® MediClean forte (Dr. Weigert)<br />

Sekusept ® aktiv (Ecolab)<br />

Thermosept ® alka clean forte (Schülke & Mayr)<br />

Gigasept ® Instru AF (Schülke & Mayr) Thermosept ® RKN-zym (Schülke & Mayr)<br />

Gigazyme ® (Schülke & Mayr)<br />

Gigasept FF neu (Schülke & Mayr)<br />

Please see <strong>the</strong> manufacturer‘s instructions for conc<strong>en</strong>tration, contact time, temperature<br />

and <strong>the</strong> compatibility of materials.<br />

Important information<br />

Wipe cleaning and wipe d<strong>is</strong>infection: All surfaces have to be wiped with a clean (d<strong>is</strong>posable)<br />