Datasheet - PMCCatalogue

Datasheet - PMCCatalogue

Datasheet - PMCCatalogue

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical data<br />

Filter housing ( M a t e r i a l s )<br />

• Head: Anodised Aluminium<br />

• Housing: Anodised A l u m i n i u m<br />

• Bypass valve: Nylon<br />

P r e s s u re<br />

• Working pre s s u re: 60 bar (6 MPa)<br />

• Test pre s s u re: 90 bar (9 MPa)<br />

• Burst pre s s u re: 180 bar (18 MPa)<br />

• Pulsed pre s s u re fatigue test: 1.000.000 cycles<br />

with pre s s u re from 0 to 60 bar (6 MPa)<br />

Te m p e r a t u r e<br />

• From -25°C to +110°C<br />

Bypass valve<br />

• Opening pre s s u re 3.5 bar ±10%<br />

• Other opening pre s s u res on re q u e s t .<br />

Δp Elements type<br />

• Series N and W elements: 20 bar<br />

• Oil flow from exterior to interior.<br />

S e a l s<br />

• Standard NBR series A<br />

• Optional FPM<br />

series V<br />

Weights (kg)<br />

L e n g t h<br />

• LMP210 - 1 3.5<br />

• LMP210 -2 4.4<br />

• LMP210 - 3 5 . 4<br />

Volumes (d m 3 )<br />

L e n g t h<br />

• LMP210 - 1 1.5<br />

• LMP210 -2 2<br />

• LMP210 - 3 2.7<br />

Connections<br />

In-line Inlet/Outlet LMP 210<br />

C o m p a t i b i l i t y<br />

• Housings compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

synthetic fluids, water and glycol.<br />

• The filter elements are compatible with:<br />

Mineral oils to ISO 2943, Synthetic fluids<br />

Aqueous emulsions, water and glycol<br />

(series W re q u i re d ).<br />

• NBR seals series A, compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

synthetic fluids, water and glycol.<br />

• V series FPM seals, compatible with:<br />

Synthetic fluids type HS-HFDR-HFDS-HFDU<br />

To ISO 2943<br />

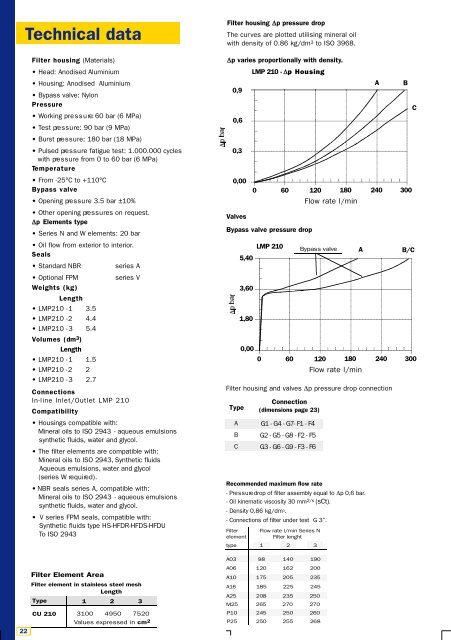

Filter housing Δp pressure drop<br />

The curves are plotted utilising mineral oil<br />

with density of 0.86 kg/dm 3 to ISO 3968.<br />

Δp varies proportionally with density.<br />

0 , 9<br />

0 , 6<br />

0 , 3<br />

0 , 0 0<br />

Valves<br />

5 , 4 0<br />

3 , 6 0<br />

1 , 8 0<br />

0 , 0 0<br />

LMP 210 - Δp Housing<br />

0 60 12 0 18 0 24 0 30 0<br />

Flow rate l/min<br />

Bypass valve pressure drop<br />

Type<br />

A<br />

B<br />

C<br />

LMP 210<br />

A<br />

A<br />

B<br />

C<br />

B / C<br />

0 60 12 0 18 0 24 0 30 0<br />

Flow rate l/min<br />

Filter housing and valves Δp pressure drop connection<br />

Connection<br />

(dimensions page 23)<br />

G1 - G4 - G7- F1 - F4<br />

G2 - G5 - G8 - F2 - F5<br />

G3 - G6 - G9 - F3 - F6<br />

Bypass valve<br />

Recommended maximum flow rate<br />

- Pre s s u re drop of filter assembly equal to Δp 0,6 bar.<br />

- Oil kinematic viscosity 30 mm 2/s ( s C t ).<br />

- Density 0,86 kg/dm 3 .<br />

- Connections of filter under test G 3”.<br />

Filter Flow rate l/min Series N<br />

e l e m e n t Filter lenght<br />

type 1 2 3<br />

2 2<br />

Filter Element Area<br />

Filter element in stainless steel mesh<br />

Length<br />

Type<br />

1 2 3<br />

CU 210 3100 4950 7520<br />

Values expressed in cm 2<br />

A 03 98 140 190<br />

A 06 120 162 200<br />

A 10 175 205 235<br />

A 16 185 225 245<br />

A 25 208 235 250<br />

M 25 265 270 270<br />

P10 245 250 260<br />

P25 250 255 268