Project Hurunui Wind Construction and Project Overview

Project Hurunui Wind Construction and Project Overview

Project Hurunui Wind Construction and Project Overview

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Project</strong> <strong>Hurunui</strong> <strong>Wind</strong> <strong>Construction</strong> Effects <strong>and</strong> Management Report<br />

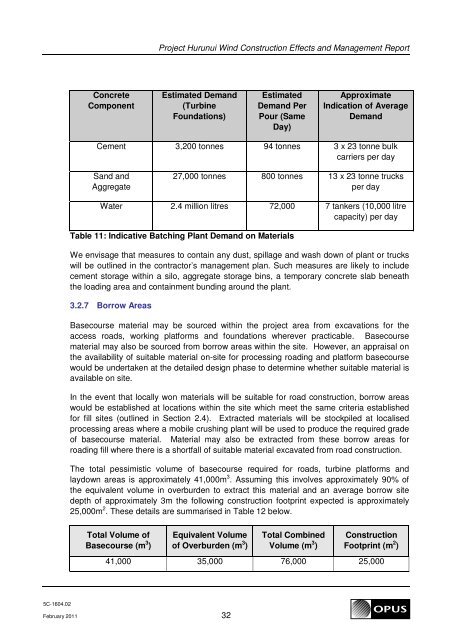

Concrete<br />

Component<br />

Estimated Dem<strong>and</strong><br />

(Turbine<br />

Foundations)<br />

Estimated<br />

Dem<strong>and</strong> Per<br />

Pour (Same<br />

Day)<br />

Approximate<br />

Indication of Average<br />

Dem<strong>and</strong><br />

Cement 3,200 tonnes 94 tonnes 3 x 23 tonne bulk<br />

carriers per day<br />

S<strong>and</strong> <strong>and</strong><br />

Aggregate<br />

27,000 tonnes 800 tonnes 13 x 23 tonne trucks<br />

per day<br />

Water 2.4 million litres 72,000 7 tankers (10,000 litre<br />

capacity) per day<br />

Table 11: Indicative Batching Plant Dem<strong>and</strong> on Materials<br />

We envisage that measures to contain any dust, spillage <strong>and</strong> wash down of plant or trucks<br />

will be outlined in the contractor’s management plan. Such measures are likely to include<br />

cement storage within a silo, aggregate storage bins, a temporary concrete slab beneath<br />

the loading area <strong>and</strong> containment bunding around the plant.<br />

3.2.7 Borrow Areas<br />

Basecourse material may be sourced within the project area from excavations for the<br />

access roads, working platforms <strong>and</strong> foundations wherever practicable. Basecourse<br />

material may also be sourced from borrow areas within the site. However, an appraisal on<br />

the availability of suitable material on-site for processing roading <strong>and</strong> platform basecourse<br />

would be undertaken at the detailed design phase to determine whether suitable material is<br />

available on site.<br />

In the event that locally won materials will be suitable for road construction, borrow areas<br />

would be established at locations within the site which meet the same criteria established<br />

for fill sites (outlined in Section 2.4). Extracted materials will be stockpiled at localised<br />

processing areas where a mobile crushing plant will be used to produce the required grade<br />

of basecourse material. Material may also be extracted from these borrow areas for<br />

roading fill where there is a shortfall of suitable material excavated from road construction.<br />

The total pessimistic volume of basecourse required for roads, turbine platforms <strong>and</strong><br />

laydown areas is approximately 41,000m 3 . Assuming this involves approximately 90% of<br />

the equivalent volume in overburden to extract this material <strong>and</strong> an average borrow site<br />

depth of approximately 3m the following construction footprint expected is approximately<br />

25,000m 2 . These details are summarised in Table 12 below.<br />

Total Volume of<br />

Basecourse (m 3 )<br />

Equivalent Volume<br />

of Overburden (m 3 )<br />

Total Combined<br />

Volume (m 3 )<br />

<strong>Construction</strong><br />

Footprint (m 2 )<br />

41,000 35,000 76,000 25,000<br />

5C-1604.02<br />

February 2011 32