Project Hurunui Wind Construction and Project Overview

Project Hurunui Wind Construction and Project Overview

Project Hurunui Wind Construction and Project Overview

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Project</strong> <strong>Hurunui</strong> <strong>Wind</strong> <strong>Construction</strong> Effects <strong>and</strong> Management Report<br />

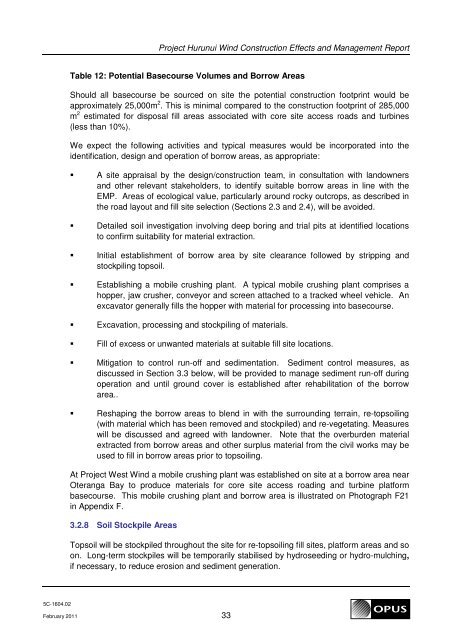

Table 12: Potential Basecourse Volumes <strong>and</strong> Borrow Areas<br />

Should all basecourse be sourced on site the potential construction footprint would be<br />

approximately 25,000m 2 . This is minimal compared to the construction footprint of 285,000<br />

m 2 estimated for disposal fill areas associated with core site access roads <strong>and</strong> turbines<br />

(less than 10%).<br />

We expect the following activities <strong>and</strong> typical measures would be incorporated into the<br />

identification, design <strong>and</strong> operation of borrow areas, as appropriate:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

A site appraisal by the design/construction team, in consultation with l<strong>and</strong>owners<br />

<strong>and</strong> other relevant stakeholders, to identify suitable borrow areas in line with the<br />

EMP. Areas of ecological value, particularly around rocky outcrops, as described in<br />

the road layout <strong>and</strong> fill site selection (Sections 2.3 <strong>and</strong> 2.4), will be avoided.<br />

Detailed soil investigation involving deep boring <strong>and</strong> trial pits at identified locations<br />

to confirm suitability for material extraction.<br />

Initial establishment of borrow area by site clearance followed by stripping <strong>and</strong><br />

stockpiling topsoil.<br />

Establishing a mobile crushing plant. A typical mobile crushing plant comprises a<br />

hopper, jaw crusher, conveyor <strong>and</strong> screen attached to a tracked wheel vehicle. An<br />

excavator generally fills the hopper with material for processing into basecourse.<br />

Excavation, processing <strong>and</strong> stockpiling of materials.<br />

Fill of excess or unwanted materials at suitable fill site locations.<br />

Mitigation to control run-off <strong>and</strong> sedimentation. Sediment control measures, as<br />

discussed in Section 3.3 below, will be provided to manage sediment run-off during<br />

operation <strong>and</strong> until ground cover is established after rehabilitation of the borrow<br />

area..<br />

Reshaping the borrow areas to blend in with the surrounding terrain, re-topsoiling<br />

(with material which has been removed <strong>and</strong> stockpiled) <strong>and</strong> re-vegetating. Measures<br />

will be discussed <strong>and</strong> agreed with l<strong>and</strong>owner. Note that the overburden material<br />

extracted from borrow areas <strong>and</strong> other surplus material from the civil works may be<br />

used to fill in borrow areas prior to topsoiling.<br />

At <strong>Project</strong> West <strong>Wind</strong> a mobile crushing plant was established on site at a borrow area near<br />

Oteranga Bay to produce materials for core site access roading <strong>and</strong> turbine platform<br />

basecourse. This mobile crushing plant <strong>and</strong> borrow area is illustrated on Photograph F21<br />

in Appendix F.<br />

3.2.8 Soil Stockpile Areas<br />

Topsoil will be stockpiled throughout the site for re-topsoiling fill sites, platform areas <strong>and</strong> so<br />

on. Long-term stockpiles will be temporarily stabilised by hydroseeding or hydro-mulching,<br />

if necessary, to reduce erosion <strong>and</strong> sediment generation.<br />

5C-1604.02<br />

February 2011 33