ASPIRE Spring 09 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 09 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 09 - Aspire - The Concrete Bridge Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Longitudinal view of <strong>Bridge</strong> 22 on<br />

Road 431 in Israel, built in precast<br />

segmental cantilever construction.<br />

Photo: Finley Engineering Group Inc.<br />

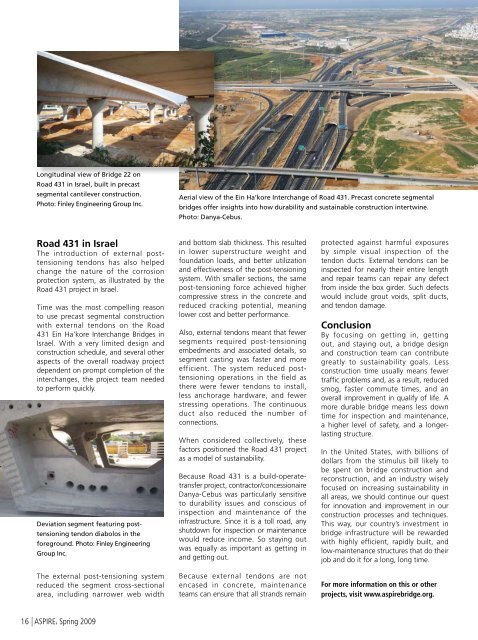

Aerial view of the Ein Ha’kore Interchange of Road 431. Precast concrete segmental<br />

bridges offer insights into how durability and sustainable construction intertwine.<br />

Photo: Danya-Cebus.<br />

Road 431 in Israel<br />

<strong>The</strong> introduction of external posttensioning<br />

tendons has also helped<br />

change the nature of the corrosion<br />

protection system, as illustrated by the<br />

Road 431 project in Israel.<br />

Time was the most compelling reason<br />

to use precast segmental construction<br />

with external tendons on the Road<br />

431 Ein Ha’kore Interchange <strong>Bridge</strong>s in<br />

Israel. With a very limited design and<br />

construction schedule, and several other<br />

aspects of the overall roadway project<br />

dependent on prompt completion of the<br />

interchanges, the project team needed<br />

to perform quickly.<br />

Deviation segment featuring posttensioning<br />

tendon diabolos in the<br />

foreground. Photo: Finley Engineering<br />

Group Inc.<br />

<strong>The</strong> external post-tensioning system<br />

reduced the segment cross-sectional<br />

area, including narrower web width<br />

and bottom slab thickness. This resulted<br />

in lower superstructure weight and<br />

foundation loads, and better utilization<br />

and effectiveness of the post-tensioning<br />

system. With smaller sections, the same<br />

post-tensioning force achieved higher<br />

compressive stress in the concrete and<br />

reduced cracking potential, meaning<br />

lower cost and better performance.<br />

Also, external tendons meant that fewer<br />

segments required post-tensioning<br />

embedments and associated details, so<br />

segment casting was faster and more<br />

efficient. <strong>The</strong> system reduced posttensioning<br />

operations in the field as<br />

there were fewer tendons to install,<br />

less anchorage hardware, and fewer<br />

stressing operations. <strong>The</strong> continuous<br />

duct also reduced the number of<br />

connections.<br />

When considered collectively, these<br />

factors positioned the Road 431 project<br />

as a model of sustainability.<br />

Because Road 431 is a build-operatetransfer<br />

project, contractor/concessionaire<br />

Danya-Cebus was particularly sensitive<br />

to durability issues and conscious of<br />

inspection and maintenance of the<br />

infrastructure. Since it is a toll road, any<br />

shutdown for inspection or maintenance<br />

would reduce income. So staying out<br />

was equally as important as getting in<br />

and getting out.<br />

Because external tendons are not<br />

encased in concrete, maintenance<br />

teams can ensure that all strands remain<br />

protected against harmful exposures<br />

by simple visual inspection of the<br />

tendon ducts. External tendons can be<br />

inspected for nearly their entire length<br />

and repair teams can repair any defect<br />

from inside the box girder. Such defects<br />

would include grout voids, split ducts,<br />

and tendon damage.<br />

Conclusion<br />

By focusing on getting in, getting<br />

out, and staying out, a bridge design<br />

and construction team can contribute<br />

greatly to sustainability goals. Less<br />

construction time usually means fewer<br />

traffic problems and, as a result, reduced<br />

smog, faster commute times, and an<br />

overall improvement in qualify of life. A<br />

more durable bridge means less down<br />

time for inspection and maintenance,<br />

a higher level of safety, and a longerlasting<br />

structure.<br />

In the United States, with billions of<br />

dollars from the stimulus bill likely to<br />

be spent on bridge construction and<br />

reconstruction, and an industry wisely<br />

focused on increasing sustainability in<br />

all areas, we should continue our quest<br />

for innovation and improvement in our<br />

construction processes and techniques.<br />

This way, our country’s investment in<br />

bridge infrastructure will be rewarded<br />

with highly efficient, rapidly built, and<br />

low-maintenance structures that do their<br />

job and do it for a long, long time.<br />

For more information on this or other<br />

projects, visit www.aspirebridge.org.<br />

16 | <strong>ASPIRE</strong>, <strong>Spring</strong> 20<strong>09</strong>