2009 - Jaarverslag

2009 - Jaarverslag

2009 - Jaarverslag

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

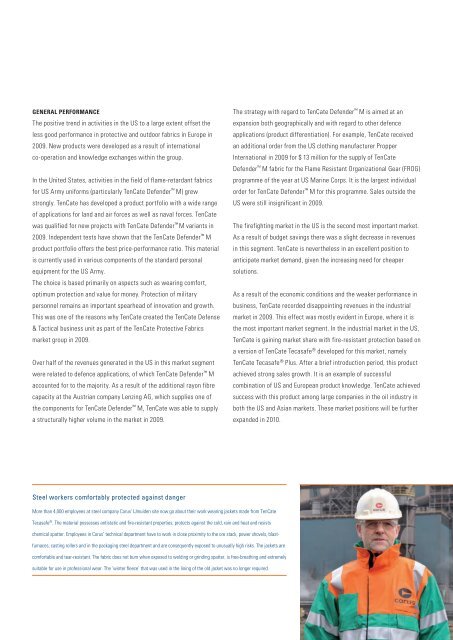

GENERAL PERFORMANCEThe positive trend in activities in the US to a large extent offset theless good performance in protective and outdoor fabrics in Europe in<strong>2009</strong>. New products were developed as a result of internationalco-operation and knowledge exchanges within the group.In the United States, activities in the field of flame-retardant fabricsfor US Army uniforms (particularly TenCate Defender M) grewstrongly. TenCate has developed a product portfolio with a wide rangeof applications for land and air forces as well as naval forces. TenCatewas qualified for new projects with TenCate Defender M variants in<strong>2009</strong>. Independent tests have shown that the TenCate Defender Mproduct portfolio offers the best price-performance ratio. This materialis currently used in various components of the standard personalequipment for the US Army.The choice is based primarily on aspects such as wearing comfort,optimum protection and value for money. Protection of militarypersonnel remains an important spearhead of innovation and growth.This was one of the reasons why TenCate created the TenCate Defense& Tactical business unit as part of the TenCate Protective Fabricsmarket group in <strong>2009</strong>.Over half of the revenues generated in the US in this market segmentwere related to defence applications, of which TenCate Defender Maccounted for to the majority. As a result of the additional rayon fibrecapacity at the Austrian company Lenzing AG, which supplies one ofthe components for TenCate Defender M, TenCate was able to supplya structurally higher volume in the market in <strong>2009</strong>.The strategy with regard to TenCate Defender M is aimed at anexpansion both geographically and with regard to other defenceapplications (product differentiation). For example, TenCate receivedan additional order from the US clothing manufacturer PropperInternational in <strong>2009</strong> for $ 13 million for the supply of TenCateDefender M fabric for the Flame Resistant Organizational Gear (FROG)programme of the year at US Marine Corps. It is the largest individualorder for TenCate Defender M for this programme. Sales outside theUS were still insignificant in <strong>2009</strong>.The firefighting market in the US is the second most important market.As a result of budget savings there was a slight decrease in revenuesin this segment. TenCate is nevertheless in an excellent position toanticipate market demand, given the increasing need for cheapersolutions.As a result of the economic conditions and the weaker performance inbusiness, TenCate recorded disappointing revenues in the industrialmarket in <strong>2009</strong>. This effect was mostly evident in Europe, where it isthe most important market segment. In the industrial market in the US,TenCate is gaining market share with fire-resistant protection based ona version of TenCate Tecasafe ® developed for this market, namelyTenCate Tecasafe ® Plus. After a brief introduction period, this productachieved strong sales growth. It is an example of successfulcombination of US and European product knowledge. TenCate achievedsuccess with this product among large companies in the oil industry inboth the US and Asian markets. These market positions will be furtherexpanded in 2010.Steel workers comfortably protected against dangerMore than 4,000 employees at steel company Corus’ IJmuiden site now go about their work wearing jackets made from TenCateTecasafe ® . The material possesses antistatic and fire-resistant properties, protects against the cold, rain and heat and resistschemical spatter. Employees in Corus’ technical department have to work in close proximity to the ore stack, power shovels, blastfurnaces,casting rollers and in the packaging steel department and are consequently exposed to unusually high risks. The jackets arecomfortable and tear-resistant. The fabric does not burn when exposed to welding or grinding spatter, is free-breathing and extremelysuitable for use in professional wear. The ‘winter fleece’ that was used in the lining of the old jacket was no longer required.Annual Report <strong>2009</strong> 35