2009 - Jaarverslag

2009 - Jaarverslag

2009 - Jaarverslag

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

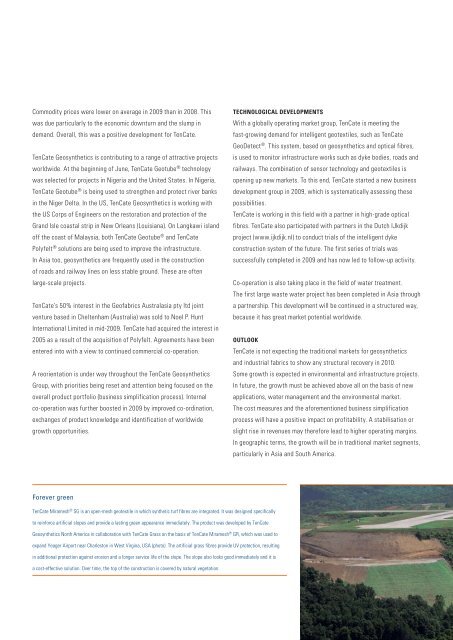

Commodity prices were lower on average in <strong>2009</strong> than in 2008. Thiswas due particularly to the economic downturn and the slump indemand. Overall, this was a positive development for TenCate.TenCate Geosynthetics is contributing to a range of attractive projectsworldwide. At the beginning of June, TenCate Geotube ® technologywas selected for projects in Nigeria and the United States. In Nigeria,TenCate Geotube ® is being used to strengthen and protect river banksin the Niger Delta. In the US, TenCate Geosynthetics is working withthe US Corps of Engineers on the restoration and protection of theGrand Isle coastal strip in New Orleans (Louisiana). On Langkawi islandoff the coast of Malaysia, both TenCate Geotube ® and TenCatePolyfelt ® solutions are being used to improve the infrastructure.In Asia too, geosynthetics are frequently used in the constructionof roads and railway lines on less stable ground. These are oftenlarge-scale projects.TenCate’s 50% interest in the Geofabrics Australasia pty ltd jointventure based in Cheltenham (Australia) was sold to Noel P. HuntInternational Limited in mid-<strong>2009</strong>. TenCate had acquired the interest in2005 as a result of the acquisition of Polyfelt. Agreements have beenentered into with a view to continued commercial co-operation.A reorientation is under way throughout the TenCate GeosyntheticsGroup, with priorities being reset and attention being focused on theoverall product portfolio (business simplification process). Internalco-operation was further boosted in <strong>2009</strong> by improved co-ordination,exchanges of product knowledge and identification of worldwidegrowth opportunities.TECHNOLOGICAL DEVELOPMENTSWith a globally operating market group, TenCate is meeting thefast-growing demand for intelligent geotextiles, such as TenCateGeoDetect ® . This system, based on geosynthetics and optical fibres,is used to monitor infrastructure works such as dyke bodies, roads andrailways. The combination of sensor technology and geotextiles isopening up new markets. To this end, TenCate started a new businessdevelopment group in <strong>2009</strong>, which is systematically assessing thesepossibilities.TenCate is working in this field with a partner in high-grade opticalfibres. TenCate also participated with partners in the Dutch IJkdijkproject (www.ijkdijk.nl) to conduct trials of the intelligent dykeconstruction system of the future. The first series of trials wassuccessfully completed in <strong>2009</strong> and has now led to follow-up activity.Co-operation is also taking place in the field of water treatment.The first large waste water project has been completed in Asia througha partnership. This development will be continued in a structured way,because it has great market potential worldwide.OUTLOOKTenCate is not expecting the traditional markets for geosyntheticsand industrial fabrics to show any structural recovery in 2010.Some growth is expected in environmental and infrastructure projects.In future, the growth must be achieved above all on the basis of newapplications, water management and the environmental market.The cost measures and the aforementioned business simplificationprocess will have a positive impact on profitability. A stabilisation orslight rise in revenues may therefore lead to higher operating margins.In geographic terms, the growth will be in traditional market segments,particularly in Asia and South America.Forever greenTenCate Miramesh ® SG is an open-mesh geotextile in which synthetic turf fibres are integrated. It was designed specificallyto reinforce artificial slopes and provide a lasting green appearance immediately. The product was developed by TenCateGeosynthetics North America in collaboration with TenCate Grass on the basis of TenCate Miramesh ® GR, which was used toexpand Yeager Airport near Charleston in West Virgina, USA (photo). The artificial grass fibres provide UV protection, resultingin additional protection against erosion and a longer service life of the slope. The slope also looks good immediately and it isa cost-effective solution. Over time, the top of the construction is covered by natural vegetation.Annual Report <strong>2009</strong> 45