Distillieries - Environmental Clearance

Distillieries - Environmental Clearance

Distillieries - Environmental Clearance

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

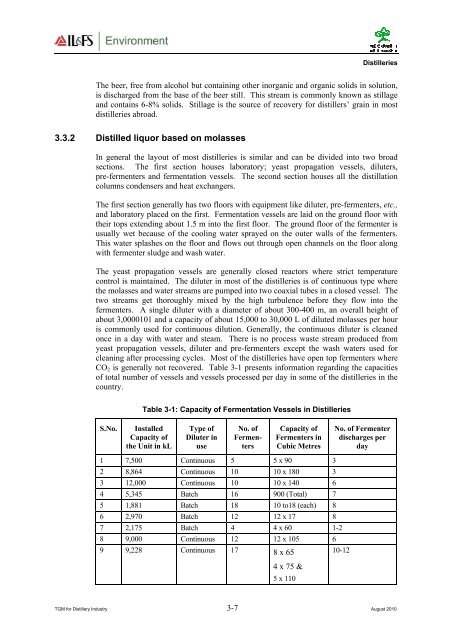

DistilleriesThe beer, free from alcohol but containing other inorganic and organic solids in solution,is discharged from the base of the beer still. This stream is commonly known as stillageand contains 6-8% solids. Stillage is the source of recovery for distillers’ grain in mostdistilleries abroad.3.3.2 Distilled liquor based on molassesIn general the layout of most distilleries is similar and can be divided into two broadsections. The first section houses laboratory; yeast propagation vessels, diluters,pre-fermenters and fermentation vessels. The second section houses all the distillationcolumns condensers and heat exchangers.The first section generally has two floors with equipment like diluter, pre-fermenters, etc.,and laboratory placed on the first. Fermentation vessels are laid on the ground floor withtheir tops extending about 1.5 m into the first floor. The ground floor of the fermenter isusually wet because of the cooling water sprayed on the outer walls of the fermenters.This water splashes on the floor and flows out through open channels on the floor alongwith fermenter sludge and wash water.The yeast propagation vessels are generally closed reactors where strict temperaturecontrol is maintained. The diluter in most of the distilleries is of continuous type wherethe molasses and water streams are pumped into two coaxial tubes in a closed vessel. Thetwo streams get thoroughly mixed by the high turbulence before they flow into thefermenters. A single diluter with a diameter of about 300-400 m, an overall height ofabout 3,0000101 and a capacity of about 15,000 to 30,000 L of diluted molasses per houris commonly used for continuous dilution. Generally, the continuous diluter is cleanedonce in a day with water and steam. There is no process waste stream produced fromyeast propagation vessels, diluter and pre-fermenters except the wash waters used forcleaning after processing cycles. Most of the distilleries have open top fermenters whereCO 2 is generally not recovered. Table 3-1 presents information regarding the capacitiesof total number of vessels and vessels processed per day in some of the distilleries in thecountry.Table 3-1: Capacity of Fermentation Vessels in DistilleriesS.No.InstalledCapacity ofthe Unit in kLType ofDiluter inuseNo. ofFermentersCapacity ofFermenters inCubic MetresNo. of Fermenterdischarges perday1 7,500 Continuous 5 5 x 90 32 8,864 Continuous 10 10 x 180 33 12,000 Continuous 10 10 x 140 64 5,345 Batch 16 900 (Total) 75 1,881 Batch 18 10 to18 (each) 86 2,970 Batch 12 12 x 17 87 2,175 Batch 4 4 x 60 1-28 9,000 Continuous 12 12 x 105 69 9,228 Continuous 17 8 x 654 x 75 &5 x 11010-12TGM for Distillery Industry 3-7 August 2010