Distillieries - Environmental Clearance

Distillieries - Environmental Clearance

Distillieries - Environmental Clearance

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

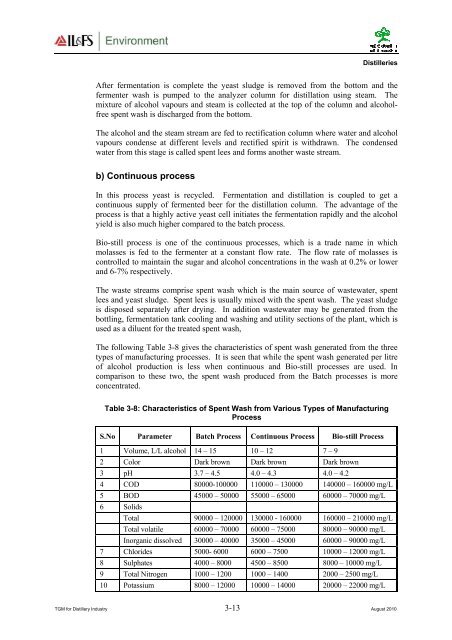

DistilleriesAfter fermentation is complete the yeast sludge is removed from the bottom and thefermenter wash is pumped to the analyzer column for distillation using steam. Themixture of alcohol vapours and steam is collected at the top of the column and alcoholfreespent wash is discharged from the bottom.The alcohol and the steam stream are fed to rectification column where water and alcoholvapours condense at different levels and rectified spirit is withdrawn. The condensedwater from this stage is called spent lees and forms another waste stream.b) Continuous processIn this process yeast is recycled. Fermentation and distillation is coupled to get acontinuous supply of fermented beer for the distillation column. The advantage of theprocess is that a highly active yeast cell initiates the fermentation rapidly and the alcoholyield is also much higher compared to the batch process.Bio-still process is one of the continuous processes, which is a trade name in whichmolasses is fed to the fermenter at a constant flow rate. The flow rate of molasses iscontrolled to maintain the sugar and alcohol concentrations in the wash at 0.2% or lowerand 6-7% respectively.The waste streams comprise spent wash which is the main source of wastewater, spentlees and yeast sludge. Spent lees is usually mixed with the spent wash. The yeast sludgeis disposed separately after drying. In addition wastewater may be generated from thebottling, fermentation tank cooling and washing and utility sections of the plant, which isused as a diluent for the treated spent wash,The following Table 3-8 gives the characteristics of spent wash generated from the threetypes of manufacturing processes. It is seen that while the spent wash generated per litreof alcohol production is less when continuous and Bio-still processes are used. Incomparison to these two, the spent wash produced from the Batch processes is moreconcentrated.Table 3-8: Characteristics of Spent Wash from Various Types of ManufacturingProcessS.No Parameter Batch Process Continuous Process Bio-still Process1 Volume, L/L alcohol 14 – 15 10 – 12 7 – 92 Color Dark brown Dark brown Dark brown3 pH 3.7 – 4.5 4.0 – 4.3 4.0 – 4.24 COD 80000-100000 110000 – 130000 140000 – 160000 mg/L5 BOD 45000 – 50000 55000 – 65000 60000 – 70000 mg/L6 SolidsTotal 90000 – 120000 130000 - 160000 160000 – 210000 mg/LTotal volatile 60000 – 70000 60000 – 75000 80000 – 90000 mg/LInorganic dissolved 30000 – 40000 35000 – 45000 60000 – 90000 mg/L7 Chlorides 5000- 6000 6000 – 7500 10000 – 12000 mg/L8 Sulphates 4000 – 8000 4500 – 8500 8000 – 10000 mg/L9 Total Nitrogen 1000 – 1200 1000 – 1400 2000 – 2500 mg/L10 Potassium 8000 – 12000 10000 – 14000 20000 – 22000 mg/LTGM for Distillery Industry 3-13 August 2010