- Page 5 and 6: Table of Contents4.10 Public Consul

- Page 7 and 8: AcronymsTable 5-1: Roles and Respon

- Page 10 and 11: AcronymsAnnexure XIIComposition of

- Page 13 and 14: ET{RT4 T}ETJAIRAM RAMESHRk?rq df (a

- Page 15 and 16: 1.INTRODUCTION TO THE TECHNICAL EIA

- Page 17 and 18: IntroductionChapter 4 (Operational

- Page 19 and 20: 2.CONCEPTUAL FACETS OF EIAIt is an

- Page 21 and 22: Conceptual Facets of EIA2.3.1 Tools

- Page 23 and 24: Conceptual Facets of EIAof wastewat

- Page 25 and 26: Conceptual Facets of EIAa plan for

- Page 27 and 28: Conceptual Facets of EIASustainable

- Page 29 and 30: Conceptual Facets of EIA2.5 Types o

- Page 32 and 33: Conceptual Facets of EIATemporary o

- Page 34 and 35: Conceptual Facets of EIApossible ex

- Page 36 and 37: Distilleries3.ABOUT DISTILLERIES IN

- Page 38 and 39: Distilleriescountry received the sa

- Page 40 and 41: Distilleriesc) DistilleryIn India,

- Page 42 and 43: DistilleriesThe beer, free from alc

- Page 44 and 45: DistilleriesUsemaking IMFL and forB

- Page 48 and 49: DistilleriesAfter fermentation is c

- Page 50 and 51: DistilleriesSince the reaction is e

- Page 52 and 53: Distilleries3.5.1 Cellulosic ethano

- Page 54 and 55: DistilleriesFigure 3-5: Preliminary

- Page 56 and 57: Distilleries3.6 Raw Material Inputs

- Page 58 and 59: DistilleriesHeat MJ/hL 85-120Electr

- Page 60 and 61: DistilleriesD. Grain and liquid sti

- Page 62 and 63: Distilleriesextraction of organic s

- Page 64 and 65: Distilleriesliquid is then heated i

- Page 66 and 67: Distilleries3.7.6 Wine manufacturin

- Page 68 and 69: DistilleriesThe grist dust generate

- Page 70 and 71: DistilleriesEmission SourcePossible

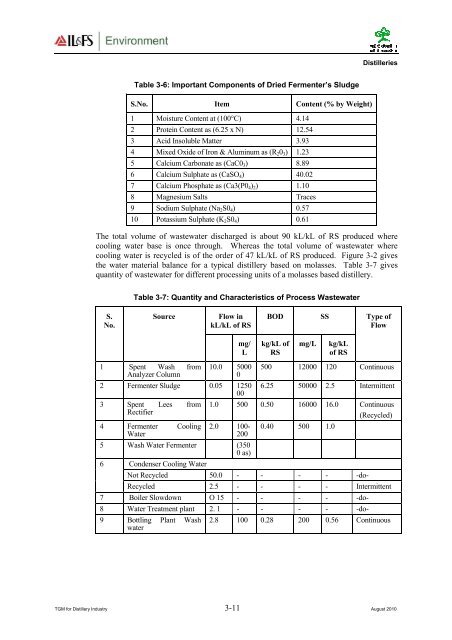

- Page 72 and 73: DistilleriesThe information furnish

- Page 74 and 75: Distilleriesthe effluent and compos

- Page 76 and 77: Distilleries3.12.2.1 Industry speci

- Page 78 and 79: 4.OPERATIONAL ASPECTS OF EIAPrior e

- Page 80 and 81: Operational Aspects of an EIAFigure

- Page 82 and 83: Operational Aspects of an EIA4.2 Sc

- Page 84 and 85: Operational Aspects of an EIANote:M

- Page 86 and 87: Operational Aspects of an EIAThe fi

- Page 88 and 89: Operational Aspects of an EIAHoweve

- Page 90 and 91: Operational Aspects of an EIAPRE-CO

- Page 92 and 93: Operational Aspects of an EIAPRE-CO

- Page 94 and 95: Operational Aspects of an EIA9) Det

- Page 96 and 97:

Operational Aspects of an EIA- Prov

- Page 98 and 99:

Operational Aspects of an EIAFigure

- Page 100 and 101:

Operational Aspects of an EIA4.4.2.

- Page 102 and 103:

Operational Aspects of an EIA4.4.3

- Page 104 and 105:

Operational Aspects of an EIALegisl

- Page 106 and 107:

Operational Aspects of an EIAthat h

- Page 108 and 109:

Operational Aspects of an EIAFigure

- Page 110 and 111:

Operational Aspects of an EIARespon

- Page 112 and 113:

Operational Aspects of an EIAEmploy

- Page 114 and 115:

Operational Aspects of an EIA4.7.2

- Page 116 and 117:

Operational Aspects of an EIAfor th

- Page 118 and 119:

Operational Aspects of an EIA2. des

- Page 120 and 121:

Operational Aspects of an EIAS.NO E

- Page 122 and 123:

Operational Aspects of an EIA In th

- Page 124 and 125:

Operational Aspects of an EIAenviro

- Page 126 and 127:

Operational Aspects of an EIAIn cas

- Page 128 and 129:

Stakeholders’ Roles and Responsib

- Page 130 and 131:

Stakeholders’ Roles and Responsib

- Page 132 and 133:

Stakeholders’ Roles and Responsib

- Page 134 and 135:

Stakeholders’ Roles and Responsib

- Page 136 and 137:

Stakeholders’ Roles and Responsib

- Page 138 and 139:

Stakeholders’ Roles and Responsib

- Page 140 and 141:

Manufacturing process of Rectified

- Page 142 and 143:

tray construction and heated by ste

- Page 144 and 145:

Figure 1: Process flow of Fermentat

- Page 146 and 147:

Table 1vii

- Page 148 and 149:

Table 3Spent Wash Characteristics F

- Page 150 and 151:

SL.NO.LEGALINSTRUMENT(TYPE,REFERENC

- Page 152 and 153:

8 Manufacture Storageand Import ofH

- Page 154 and 155:

Section 37: Explosion or inflammabl

- Page 156 and 157:

commissioner)20 The Motor Vehicle A

- Page 158 and 159:

ANNEXURE IIIGeneral Standards for D

- Page 160 and 161:

18. Hexavalent chromium (as Cr+6) m

- Page 162 and 163:

2. The user should make efforts to

- Page 164 and 165:

ANNEXURE IVForm 1 (Application Form

- Page 166 and 167:

S. No. Item Details14. Interlined P

- Page 168 and 169:

S.No. Information/Checklist confirm

- Page 170 and 171:

S.No. Information/Checklist confirm

- Page 172 and 173:

8. Risk of accidents during constru

- Page 174 and 175:

(IV) PROPOSED TERMS OF REFERENCE FO

- Page 176 and 177:

Details of Critically Polluted Indu

- Page 178 and 179:

16 Cuddalore (Tamil Nadu)CEPI-77.45

- Page 180 and 181:

e made available showing spatial bo

- Page 182 and 183:

Table 1: Points for Possible Covera

- Page 184 and 185:

ii.Details of selected siteStatus o

- Page 186 and 187:

TYPES OF MONITORING AND NETWORK DES

- Page 188 and 189:

and proportional to temporal dynami

- Page 190 and 191:

GUIDANCE FOR ASSESSMENT OF BASELINE

- Page 192 and 193:

AttributesAquatic weedsEnumeration

- Page 194 and 195:

ANNEXURE IXSources of Secondary Dat

- Page 196 and 197:

Information8. Nature of Terrain, to

- Page 198 and 199:

Annexure VIIB: Summary of Available

- Page 200 and 201:

13. Department of Ocean Development

- Page 202 and 203:

19. Indian Meteorology Department S

- Page 204 and 205:

32. National Botanical Research Ins

- Page 206 and 207:

ANNEXURE XImpact Prediction Tools

- Page 208 and 209:

MODEL APPLICATION REMARKS REMARKS F

- Page 210 and 211:

MODEL APPLICATION REMARKS REMARKS F

- Page 212 and 213:

MODEL APPLICATION REMARKS REMARKS F

- Page 214 and 215:

Model Application Remarks(SWMM)Batt

- Page 216 and 217:

Name Relevance Applications Remarks

- Page 218 and 219:

RelevanceName Application Remarksen

- Page 220 and 221:

1 Name (in block letters)2 Address

- Page 222 and 223:

Composition of the EAC/SEACThe Memb

- Page 224 and 225:

Best Practices & Latest Technologie

- Page 226 and 227:

For installations affected by seaso

- Page 228 and 229:

REFERENCESReference DocumentsMinist

- Page 230:

IL&FS Ecosmart LimitedFlat # 408, S