- Page 2:

Chapter 1Introduction and Basic Con

- Page 5 and 6:

4-2 Energy Balance for Closed Syste

- Page 7 and 8:

7-2 The Increase of Entropy Princip

- Page 9 and 10:

Development of Gas TurbinesDeviatio

- Page 11 and 12:

ProblemsChapter 13Gas Mixtures13-1

- Page 13:

17-1 Stagnation Properties17-2 Spee

- Page 16 and 17:

Appendix 2Property Tables and Chart

- Page 18 and 19:

PREFACEBACKGROUNDThermodynamics is

- Page 20 and 21:

Preface | xixcoverage of oblique sh

- Page 22 and 23:

starts with the simplest case and a

- Page 24 and 25:

A CHOICE OF SI ALONE OR SI/ENGLISH

- Page 26 and 27:

Chapter 1INTRODUCTION AND BASIC CON

- Page 28 and 29:

particles to determine the pressure

- Page 30 and 31:

did not find universal acceptance u

- Page 32 and 33:

1 J 1 N # m (1-3)Chapter 1 | 7wher

- Page 34 and 35:

mN kgs 2andlbf 32.174 ftlbm s 2 C

- Page 36 and 37:

devices is best studied by selectin

- Page 38 and 39:

diameter) is much larger than the m

- Page 40 and 41:

A system is called a simple compres

- Page 42 and 43:

time in a periodic manner, and the

- Page 44 and 45:

points on a plane, these two measur

- Page 46 and 47:

We emphasize that the magnitudes of

- Page 48 and 49:

Chapter 1 | 23P gageP vacP atmP atm

- Page 50 and 51:

the pressure difference between poi

- Page 52 and 53:

Chapter 1 | 27Solution The reading

- Page 54 and 55:

Other Pressure Measurement DevicesA

- Page 56 and 57:

Chapter 1 | 31EXAMPLE 1-8Measuring

- Page 58 and 59:

Chapter 1 | 33Performing the integr

- Page 60 and 61:

Keep in mind that the solutions you

- Page 62 and 63:

Chapter 1 | 37which is an exact mat

- Page 64 and 65:

Chapter 1 | 39SUMMARYIn this chapte

- Page 66 and 67:

1-23C What is a steady-flow process

- Page 68 and 69:

60 NP atm = 95 kPam P = 4 kgChapter

- Page 70 and 71:

unknown density is poured into one

- Page 72 and 73:

1-96 The average temperature of the

- Page 74 and 75:

Chapter 1 | 491-112E Consider a U-t

- Page 76 and 77:

Chapter 2ENERGY, ENERGY TRANSFER, A

- Page 78 and 79:

Now if asked to name the energy tra

- Page 80 and 81:

Some Physical Insight to Internal E

- Page 82 and 83:

uranium-235 atom absorbs a neutron

- Page 84 and 85:

gz b E # mech m # e mech m # a P

- Page 86 and 87:

A process during which there is no

- Page 88 and 89:

Heat and work are directional quant

- Page 90 and 91:

Chapter 2 | 65Solution A well-insul

- Page 92 and 93:

EXAMPLE 2-7Power Transmission by th

- Page 94 and 95:

EXAMPLE 2-8Power Needs of a Car to

- Page 96 and 97:

erty is the total energy. Note that

- Page 98 and 99:

Chapter 2 | 73of a system during a

- Page 100 and 101:

E in E out ¢E systemChapter 2

- Page 102 and 103:

Chapter 2 | 777 cents per kWh, dete

- Page 104 and 105:

all resistance heaters is 100 perce

- Page 106 and 107:

the food to the energy consumed by

- Page 108 and 109:

converted entirely from one mechani

- Page 110 and 111:

Chapter 2 | 85Then the rate at whic

- Page 112 and 113:

usually grouped as hydrocarbons (HC

- Page 114 and 115:

Chapter 2 | 89a certain amount of a

- Page 116 and 117:

mechanical energy, and thus electri

- Page 118 and 119:

Chapter 2 | 93In solids, heat condu

- Page 120 and 121:

Chapter 2 | 95In general, both e an

- Page 122 and 123:

The energy flow rate associated wit

- Page 124 and 125:

2-23C What is the caloric theory? W

- Page 126 and 127:

this escalator. What would your ans

- Page 128 and 129:

espectively. If the pressure rise o

- Page 130 and 131:

700 W/m 2 and the surrounding air t

- Page 132 and 133:

The water flow rate through the pum

- Page 134:

2-141 The roof of an electrically h

- Page 137 and 138:

cen84959_ch03.qxd 4/25/05 2:47 PM P

- Page 139 and 140:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 141 and 142:

cen84959_ch03.qxd 4/25/05 2:47 PM P

- Page 143 and 144:

cen84959_ch03.qxd 4/25/05 2:47 PM P

- Page 145 and 146:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 147 and 148:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 149 and 150:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 151 and 152:

cen84959_ch03.qxd 4/25/05 2:47 PM P

- Page 153 and 154:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 155 and 156:

cen84959_ch03.qxd 4/14/05 4:09 PM P

- Page 157 and 158:

cen84959_ch03.qxd 4/11/05 12:23 PM

- Page 159 and 160:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 161 and 162:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 163 and 164:

cen84959_ch03.qxd 4/26/05 4:40 PM P

- Page 165 and 166:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 167 and 168:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 169 and 170:

cen84959_ch03.qxd 4/25/05 2:47 PM P

- Page 171 and 172:

cen84959_ch03.qxd 4/19/05 9:40 AM P

- Page 173 and 174:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 175 and 176:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 177 and 178:

cen84959_ch03.qxd 4/11/05 12:23 PM

- Page 179 and 180:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 181 and 182:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 183 and 184:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 185 and 186:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 187 and 188:

cen84959_ch03.qxd 4/1/05 12:31 PM P

- Page 189 and 190:

cen84959_ch03.qxd 4/20/05 5:07 PM P

- Page 191 and 192:

166 | ThermodynamicsThe movingbound

- Page 193 and 194:

168 | Thermodynamicscompression pro

- Page 195 and 196:

170 | ThermodynamicsEXAMPLE 4-3Isot

- Page 197 and 198:

172 | Thermodynamicsthe gas, and (c

- Page 199 and 200:

174 | ThermodynamicsGeneral Q - W =

- Page 201 and 202:

176 | ThermodynamicsUse actual data

- Page 203 and 204:

178 | ThermodynamicsVacuumP = 0W =

- Page 205 and 206:

180 | ThermodynamicsAIRm = 1 kg300

- Page 207 and 208:

182 | ThermodynamicsAIRT, Ku, kJ/kg

- Page 209 and 210:

184 | ThermodynamicsAIR at 300 Kc v

- Page 211 and 212:

186 | ThermodynamicsEXAMPLE 4-9Heat

- Page 213 and 214:

188 | ThermodynamicsP, kPa35023AIRF

- Page 215 and 216:

190 | ThermodynamicsFor solids, the

- Page 217 and 218:

⎫ ⎪⎬⎪⎭⎫⎪⎬⎪⎭192

- Page 219 and 220:

194 | ThermodynamicsA 300-Wrefriger

- Page 221 and 222:

196 | Thermodynamicsdays.) Although

- Page 223 and 224:

198 | ThermodynamicsTABLE 4-3The ra

- Page 225 and 226:

200 | ThermodynamicsSolution A pers

- Page 227 and 228:

202 | Thermodynamics4-7 A piston-cy

- Page 229 and 230:

204 | Thermodynamics4-30 A well-ins

- Page 231 and 232:

206 | Thermodynamics(Table A-2b), a

- Page 233 and 234:

208 | Thermodynamicsa rate of 100 b

- Page 235 and 236:

210 | Thermodynamicsof carbohydrate

- Page 237 and 238:

212 | ThermodynamicsQHePV n = const

- Page 239 and 240:

214 | Thermodynamicsthe entire air

- Page 241 and 242:

216 | Thermodynamics4-149 The speci

- Page 243 and 244:

218 | Thermodynamicsduring vacuum c

- Page 245 and 246:

220 | Thermodynamics2 kgH 216 kgO 2

- Page 247 and 248:

222 | Thermodynamicsm in = 50 kgWat

- Page 249 and 250:

224 | ThermodynamicsIt states that

- Page 251 and 252:

226 | Thermodynamicswhere A jet pD

- Page 253 and 254:

228 | ThermodynamicsThe fluid enter

- Page 255 and 256:

230 | ThermodynamicsFIGURE 5-17Many

- Page 257 and 258:

232 | ThermodynamicsCVW˙eW˙shFIGU

- Page 259 and 260:

234 | ThermodynamicsEXAMPLE 5-4Dece

- Page 261 and 262:

236 | ThermodynamicsDividing by the

- Page 263 and 264:

238 | ThermodynamicsAnalysis We tak

- Page 265 and 266:

240 | Thermodynamicsu 1 = 94.79 kJ/

- Page 267 and 268:

242 | Thermodynamics50°CFluid B70

- Page 269 and 270:

244 | ThermodynamicsR-134a. .Qw,in

- Page 271 and 272:

246 | ThermodynamicsSubstituting th

- Page 273 and 274:

248 | Thermodynamicsone of these wi

- Page 275 and 276:

250 | Thermodynamicssince the initi

- Page 277 and 278:

252 | ThermodynamicsThus,andv 2 0.

- Page 279 and 280:

254 | Thermodynamicsenergy per unit

- Page 281 and 282:

256 | Thermodynamicsunsteady-flow p

- Page 283 and 284:

258 | Thermodynamics5-15 Air enters

- Page 285 and 286:

260 | ThermodynamicsTurbines and Co

- Page 287 and 288:

262 | Thermodynamicsby the incoming

- Page 289 and 290:

264 | Thermodynamicsthe furnace. Ai

- Page 291 and 292:

266 | Thermodynamicsmass flow rate

- Page 293 and 294:

268 | Thermodynamicstank exists in

- Page 295 and 296:

270 | Thermodynamicsis allowed to e

- Page 297 and 298:

272 | Thermodynamicsfind the simple

- Page 299 and 300:

274 | Thermodynamicsenters the buil

- Page 301 and 302:

276 | Thermodynamicsopened, and air

- Page 303 and 304:

278 | Thermodynamics5-212 Refrigera

- Page 305 and 306:

280 | ThermodynamicsHOTCOFFEEHeatFI

- Page 307 and 308:

282 | ThermodynamicsWATERWorkFIGURE

- Page 309 and 310:

284 | ThermodynamicsorIt can also b

- Page 311 and 312:

286 | Thermodynamicsthe cycle, even

- Page 313 and 314:

288 | ThermodynamicsSurrounding med

- Page 315 and 316:

290 | ThermodynamicsFIGURE 6-23When

- Page 317 and 318:

292 | Thermodynamicsheat to the hou

- Page 319 and 320:

294 | ThermodynamicsSystem boundary

- Page 321 and 322:

296 | ThermodynamicsINTERACTIVETUTO

- Page 323 and 324:

298 | Thermodynamics20°CHeat5°C20

- Page 325 and 326:

300 | ThermodynamicsEnergysourceat

- Page 327 and 328:

302 | Thermodynamics1Irrev.HEHigh-t

- Page 329 and 330:

304 | Thermodynamicshave the same e

- Page 331 and 332:

306 | ThermodynamicsHigh-temperatur

- Page 333 and 334:

308 | ThermodynamicsQuantity versus

- Page 335 and 336:

310 | ThermodynamicsWarm environmen

- Page 337 and 338:

312 | ThermodynamicsTABLE 6-1Typica

- Page 339 and 340:

314 | ThermodynamicsCoolairWarmairR

- Page 341 and 342:

316 | Thermodynamicswhere W net,out

- Page 343 and 344:

318 | Thermodynamicsbetween the tem

- Page 345 and 346:

320 | Thermodynamics·120 kPax = 0.

- Page 347 and 348:

322 | ThermodynamicsIf the air surr

- Page 349 and 350:

324 | ThermodynamicsSpecial Topic:

- Page 351 and 352:

326 | Thermodynamics°F temperature

- Page 353 and 354:

328 | Thermodynamics$800 more to in

- Page 355 and 356:

330 | ThermodynamicsIf heat is supp

- Page 357 and 358:

332 | ThermodynamicsReversiblecycli

- Page 359 and 360:

334 | ThermodynamicsT∆S = S 2 - S

- Page 361 and 362:

336 | ThermodynamicsProcess 1-2(rev

- Page 363 and 364:

338 | ThermodynamicsSurroundings∆

- Page 365 and 366:

T340 | ThermodynamicsP 1 s 1 ≅ sT

- Page 367 and 368:

342 | ThermodynamicsEXAMPLE 7-4Entr

- Page 369 and 370:

344 | ThermodynamicsThe power outpu

- Page 371 and 372:

346 | ThermodynamicsTT HT L4A1 2W n

- Page 373 and 374:

348 | ThermodynamicsW shHOT BODY80

- Page 375 and 376:

350 | Thermodynamicsis highly irrev

- Page 377 and 378:

352 | ThermodynamicsEXAMPLE 7-7Effe

- Page 379 and 380:

354 | ThermodynamicsThen the power

- Page 381 and 382:

356 | ThermodynamicsandT 2 P 2s 2

- Page 383 and 384:

358 | ThermodynamicsIsentropic Proc

- Page 385 and 386:

360 | ThermodynamicsThe quantity T/

- Page 387 and 388:

362 | ThermodynamicsT, RT 2 = 780 R

- Page 389 and 390:

364 | ThermodynamicsIn gas power pl

- Page 391 and 392:

366 | ThermodynamicsP 1 , T 1TURBIN

- Page 393 and 394:

368 | ThermodynamicsPP 22Work saved

- Page 395 and 396:

370 | ThermodynamicsThe compressor

- Page 397 and 398:

372 | ThermodynamicsT,°CP 1 = 3 MP

- Page 399 and 400:

374 | ThermodynamicsEXAMPLE 7-15Eff

- Page 401 and 402:

376 | ThermodynamicsT, KP 1 = 200 k

- Page 403 and 404:

378 | ThermodynamicsEntropy Change

- Page 405 and 406:

380 | ThermodynamicsS inMassHeatSys

- Page 407 and 408:

382 | Thermodynamicsor, in the rate

- Page 409 and 410:

384 | ThermodynamicsT,°C4501Thrott

- Page 411 and 412:

386 | Thermodynamics(c) The entropy

- Page 413 and 414:

388 | ThermodynamicsSubstituting, t

- Page 415 and 416:

390 | Thermodynamicsat 100°C while

- Page 417 and 418:

392 | ThermodynamicsCompressor: 125

- Page 419 and 420:

394 | ThermodynamicsThen the mass f

- Page 421 and 422:

396 | ThermodynamicsW electricMotor

- Page 423 and 424:

398 | ThermodynamicsOutsideairWallA

- Page 425 and 426:

400 | Thermodynamicsambient in a li

- Page 427 and 428:

402 | ThermodynamicsPROBLEMS*Entrop

- Page 429 and 430:

404 | Thermodynamicsthis problem. L

- Page 431 and 432:

406 | Thermodynamics7-62C Starting

- Page 433 and 434:

408 | Thermodynamics7-91 Liquid wat

- Page 435 and 436:

410 | Thermodynamicstemperature of

- Page 437 and 438:

412 | Thermodynamics7-136E In a pro

- Page 439 and 440:

414 | Thermodynamicsfull load, and

- Page 441 and 442:

416 | Thermodynamics7-174 Consider

- Page 443 and 444:

418 | Thermodynamicsare 104°C and

- Page 445 and 446:

420 | Thermodynamicswater pipe heat

- Page 447 and 448:

422 | Thermodynamicsisentropic effi

- Page 449 and 450:

424 | ThermodynamicsAIR25°C101 kPa

- Page 451 and 452:

426 | Thermodynamicsm⋅⋅W max =

- Page 453 and 454:

428 | ThermodynamicsAtmosphericairP

- Page 455 and 456:

430 | ThermodynamicsIRON200°C27°C

- Page 457 and 458:

432 | Thermodynamicsof heat to the

- Page 459 and 460:

434 | ThermodynamicsFor a heat engi

- Page 461 and 462:

436 | Thermodynamicswhen the direct

- Page 463 and 464:

438 | ThermodynamicsEnergy:Exergy:e

- Page 465 and 466:

440 | ThermodynamicsThe properties

- Page 467 and 468:

442 | ThermodynamicsHeattransferEnt

- Page 469 and 470:

444 | ThermodynamicsThis equation c

- Page 471 and 472:

446 | ThermodynamicsOutersurroundin

- Page 473 and 474:

448 | ThermodynamicsBrick27°Cwall0

- Page 475 and 476:

450 | ThermodynamicsThat is, if the

- Page 477 and 478:

452 | Thermodynamics(b) The reversi

- Page 479 and 480:

454 | Thermodynamics(a) Noting that

- Page 481 and 482:

456 | ThermodynamicsThe useful work

- Page 483 and 484:

458 | ThermodynamicsWX workm ic iSu

- Page 485 and 486:

460 | Thermodynamicscold stream, pr

- Page 487 and 488:

462 | Thermodynamics(c) The second-

- Page 489 and 490:

464 | ThermodynamicsAssumptions 1 A

- Page 491 and 492:

466 | Thermodynamics“Now I’m in

- Page 493 and 494:

468 | ThermodynamicsI have only jus

- Page 495 and 496:

470 | ThermodynamicsExergytransferb

- Page 497 and 498:

472 | Thermodynamics8-21 How much o

- Page 499 and 500:

474 | Thermodynamicsactivated to st

- Page 501 and 502:

476 | Thermodynamics8-66E Refrigera

- Page 503 and 504:

478 | Thermodynamics8-87 Ambient ai

- Page 505 and 506:

480 | Thermodynamicsof the inner an

- Page 507 and 508:

482 | Thermodynamicssteam. Neglecti

- Page 509 and 510:

484 | Thermodynamics8-137 An adiaba

- Page 512 and 513:

Chapter 9GAS POWER CYCLESTwo import

- Page 514 and 515:

Chapter 9 | 489FIGURE 9-4An automot

- Page 516 and 517:

Isothermalcompressorq out43Isentrop

- Page 518 and 519:

oom temperature (25°C, or 77°F).

- Page 520 and 521:

Initially, both the intake and the

- Page 522 and 523:

and the specific heat ratio. This i

- Page 524 and 525:

Chapter 9 | 499P 3 v 3T 3 P 2v 2T 2

- Page 526 and 527:

We now define a new quantity, the c

- Page 528 and 529:

Chapter 9 | 503Process 2-3 is a con

- Page 530 and 531:

or any kind of porous plug with a h

- Page 532 and 533:

have long been of only theoretical

- Page 534 and 535:

wherer p P 0.72(9-18)P 1 0.6Chapte

- Page 536 and 537:

2. Increasing the efficiencies of t

- Page 538 and 539:

h C w s h 4a2s h 1(9-19)2a4sw a h

- Page 540 and 541:

q regen,act h 5 h 2 (9-21)Chapter

- Page 542 and 543:

Chapter 9 | 517Discussion Note that

- Page 544 and 545:

If the number of compression and ex

- Page 546 and 547:

tion on the thermal efficiency is a

- Page 548 and 549:

emaining part of the energy release

- Page 550 and 551:

Discussion For those who are wonder

- Page 552 and 553:

Chapter 9 | 527Fuel nozzles or spra

- Page 554 and 555:

Chapter 9 | 529EXAMPLE 9-10Second-L

- Page 556 and 557:

Chapter 9 | 531use per vehicle in t

- Page 558 and 559:

Chapter 9 | 533Park in the GarageTh

- Page 560 and 561:

Chapter 9 | 535acceleration. Using

- Page 562 and 563:

Chapter 9 | 537pistons, and prevent

- Page 564 and 565:

Chapter 9 | 539PROBLEMS*Actual and

- Page 566 and 567:

modeled as polytropic with a polytr

- Page 568 and 569:

9-84 A gas-turbine power plant oper

- Page 570 and 571:

9-111 Repeat Problem 9-110 using ar

- Page 572 and 573:

9-137 Repeat Problem 9-136 using co

- Page 574 and 575:

maximum? At what pressure ratio doe

- Page 576 and 577:

Chapter 10VAPOR AND COMBINED POWER

- Page 578 and 579:

This problem could be eliminated by

- Page 580:

or,wherew pump,in v 1P 2 P 1 2h 1

- Page 583 and 584:

558 | ThermodynamicsTIDEAL CYCLETIr

- Page 585 and 586:

560 | ThermodynamicsTurbine work ou

- Page 587 and 588:

562 | ThermodynamicsT21Criticalpoin

- Page 589 and 590:

564 | ThermodynamicsTherefore, the

- Page 591 and 592:

566 | ThermodynamicsTThe reheat cyc

- Page 593 and 594:

568 | ThermodynamicsandOpen Feedwat

- Page 595 and 596:

570 | Thermodynamicswherey m # 6>m

- Page 597 and 598:

572 | ThermodynamicsSome steam leav

- Page 599 and 600:

574 | ThermodynamicsDiscussion This

- Page 601 and 602:

576 | ThermodynamicsThus,andq in 1

- Page 603 and 604:

578 | ThermodynamicsTherefore, the

- Page 605 and 606:

580 | Thermodynamics3BoilerExpansio

- Page 607 and 608:

582 | Thermodynamicscycle and thus

- Page 609 and 610:

584 | Thermodynamicsin Fig. 10-24.

- Page 611 and 612:

586 | ThermodynamicsSteam cycle:(a)

- Page 613 and 614:

588 | ThermodynamicsT2 3BoilerMercu

- Page 615 and 616:

590 | ThermodynamicsPROBLEMS*Carnot

- Page 617 and 618:

592 | Thermodynamics410 kPa. Isobut

- Page 619 and 620:

594 | ThermodynamicsRegenerative Ra

- Page 621 and 622:

596 | Thermodynamics10-58 Reconside

- Page 623 and 624:

598 | ThermodynamicsCombined Gas-Va

- Page 625 and 626:

600 | Thermodynamics120 MW. Steam e

- Page 627 and 628:

602 | Thermodynamicsvaried from 0.5

- Page 629 and 630:

604 | Thermodynamicsan engineering

- Page 632 and 633:

Chapter 11REFRIGERATION CYCLESAmajo

- Page 634 and 635:

1 ton. One ton of refrigeration is

- Page 636 and 637:

Chapter 11 | 611WARMenvironmentT3Q

- Page 638 and 639:

Chapter 11 | 613EXAMPLE 11-1The Ide

- Page 640 and 641:

the evaporator to the compressor is

- Page 642 and 643:

choice of refrigerant depends on th

- Page 644 and 645:

ator coils is highly undesirable si

- Page 646 and 647:

Chapter 11 | 621WARMenvironment7Q H

- Page 648 and 649:

Chapter 11 | 623 10.05 kg>s231270.9

- Page 650 and 651:

Chapter 11 | 625T4h 4 = 274.48 kJ/k

- Page 652 and 653:

At temperatures above the critical-

- Page 654 and 655:

All the processes described are int

- Page 656 and 657:

Chapter 11 | 631(a) The maximum and

- Page 658 and 659:

hot NH 3 H 2 O solution, which is

- Page 660 and 661:

Chapter 11 | 635this manner form a

- Page 662 and 663:

Very low temperatures can be achiev

- Page 664 and 665:

space and the power input to the co

- Page 666 and 667:

Each stage operates on the ideal va

- Page 668 and 669:

5·Q L6Heatexch.Regenerator 3 Heate

- Page 670 and 671:

0.14 MPa. The working fluid is refr

- Page 672 and 673:

Consider a vortex tube that receive

- Page 674:

Chapter 11 | 649do calculations to

- Page 677 and 678:

652 | Thermodynamicsf(x)(x+∆ x)f(

- Page 679 and 680:

654 | ThermodynamicsEXAMPLE 12-2Tot

- Page 681 and 682:

656 | ThermodynamicsFunction: z + 2

- Page 683 and 684:

658 | ThermodynamicsEXAMPLE 12-4Ver

- Page 685 and 686:

660 | Thermodynamicswhere, from Tab

- Page 687 and 688:

662 | ThermodynamicsNow we choose t

- Page 689 and 690:

664 | ThermodynamicsSpecific Heats

- Page 691 and 692:

666 | ThermodynamicsAnalysis The ch

- Page 693 and 694:

668 | Thermodynamics>T 1 = 20°C T

- Page 695 and 696:

670 | ThermodynamicsTT 2Actualproce

- Page 697 and 698:

672 | Thermodynamicsfinally along t

- Page 699 and 700:

674 | ThermodynamicsandThen the ent

- Page 701 and 702:

676 | Thermodynamics12-3C Consider

- Page 703 and 704:

678 | Thermodynamics12-63 Propane i

- Page 705 and 706:

680 | Thermodynamics(a) proportiona

- Page 707 and 708: 682 | ThermodynamicsH 26 kg+O 232 k

- Page 709 and 710: 684 | ThermodynamicsorAlso,M m a y

- Page 711 and 712: 686 | ThermodynamicsP m V m = Z m N

- Page 713 and 714: 688 | Thermodynamics(c) When Amagat

- Page 715 and 716: 690 | ThermodynamicsSimilarly, the

- Page 717 and 718: 692 | ThermodynamicsandV O2 a NR uT

- Page 719 and 720: 694 | Thermodynamicsorwhich yieldsa

- Page 721 and 722: 696 | ThermodynamicsAlso,h m1 ,idea

- Page 723 and 724: 698 | ThermodynamicsMixture:i h i,m

- Page 725 and 726: 700 | Thermodynamicsof the pure com

- Page 727 and 728: 702 | Thermodynamicsentropy generat

- Page 729 and 730: 704 | Thermodynamicsthe second-law

- Page 731 and 732: 706 | Thermodynamicswater from the

- Page 733 and 734: 708 | ThermodynamicsSUMMARYA mixtur

- Page 735 and 736: 710 | Thermodynamics13-21C How is t

- Page 737 and 738: 712 | ThermodynamicsThe mixture ent

- Page 739 and 740: 714 | Thermodynamics13-84 A rigid t

- Page 742 and 743: Chapter 14GAS-VAPOR MIXTURES AND AI

- Page 744 and 745: elow 50°C. Therefore, the enthalpy

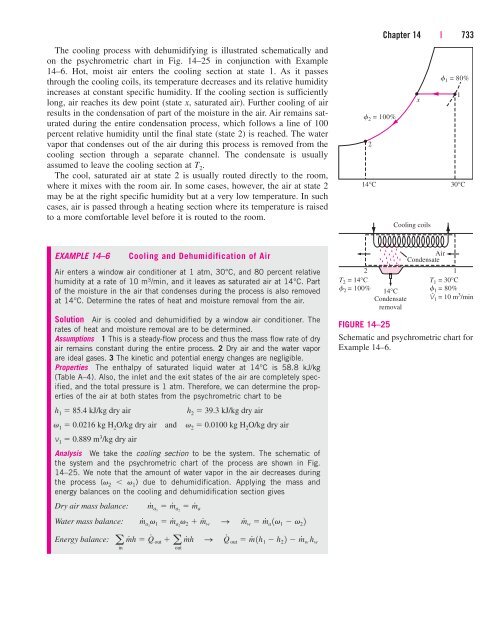

- Page 746 and 747: Chapter 14 | 721Analysis (a) The pa

- Page 748 and 749: Chapter 14 | 723starts condensing.

- Page 750 and 751: on this principle is called a sling

- Page 752 and 753: Chapter 14 | 727EXAMPLE 14-4The Use

- Page 754 and 755: the environment is close to 100 per

- Page 756 and 757: Heating with HumidificationProblems

- Page 760 and 761: Chapter 14 | 735EXAMPLE 14-7Evapora

- Page 762 and 763: Chapter 14 | 737Analysis We take th

- Page 764 and 765: Chapter 14 | 739Properties The enth

- Page 766 and 767: Chapter 14 | 741REFERENCES AND SUGG

- Page 768 and 769: 14-47 Reconsider Prob. 14-46. Deter

- Page 770 and 771: equired results. Plot the required

- Page 772 and 773: WARMWATER60 kg/s40°CAIRINLET1 atmT

- Page 774 and 775: AIRCooling coilsCondensateFIGURE P1

- Page 776 and 777: Chapter 15CHEMICAL REACTIONSIn the

- Page 778 and 779: Chapter 15 | 753TABLE 15-1A compari

- Page 780 and 781: not required.) However, notice that

- Page 782 and 783: In actual combustion processes, it

- Page 784 and 785: Chapter 15 | 759Assumptions 1 The f

- Page 786 and 787: Chapter 15 | 761The combustion equa

- Page 788 and 789: ing which chemical energy is releas

- Page 790 and 791: C 8 H 18 a th 1O 2 3.76N 2 2 S 8C

- Page 792 and 793: Q out a N r 1h° f h h°2 r1555

- Page 794 and 795: Chapter 15 | 769The h - f ° of liq

- Page 796 and 797: H prod H react (15-16)Chapter 15 |

- Page 798 and 799: Chapter 15 | 773which is lower than

- Page 800 and 801: If a gas mixture is at a relatively

- Page 802 and 803: Chapter 15 | 777EXAMPLE 15-10Second

- Page 804 and 805: Chapter 15 | 779(a) the heat transf

- Page 806 and 807: Chapter 15 | 781cal reactions, the

- Page 808 and 809:

Chapter 15 | 783In the absence of a

- Page 810 and 811:

15-42 Determine the enthalpy of com

- Page 812 and 813:

Chapter 15 | 78715-65E A constant-v

- Page 814 and 815:

air used, and (c) the volume flow r

- Page 816 and 817:

where C is a constant whose value d

- Page 818 and 819:

Chapter 16CHEMICAL AND PHASE EQUILI

- Page 820 and 821:

The differential of the Gibbs funct

- Page 822 and 823:

where g - * (T) represents the Gibb

- Page 824 and 825:

Chapter 16 | 799Analysis This is a

- Page 826 and 827:

moles of the reactants and increase

- Page 828 and 829:

Chapter 16 | 803EXAMPLE 16-4Effect

- Page 830 and 831:

Chapter 16 | 805EXAMPLE 16-5Equilib

- Page 832 and 833:

calculating the h of a reaction fro

- Page 834 and 835:

What happens if g f g g ? Obviousl

- Page 836 and 837:

two sides of a water-air interface

- Page 838 and 839:

where is the solubility. Expressin

- Page 840 and 841:

Chapter 16 | 815EXAMPLE 16-11Compos

- Page 842 and 843:

Chapter 16 | 817PROBLEMS*K P and th

- Page 844 and 845:

Simultaneous Reactions16-38C What i

- Page 846 and 847:

16-83 A constant-volume tank contai

- Page 848 and 849:

Chapter 17COMPRESSIBLE FLOWFor the

- Page 850 and 851:

stagnation pressure, stagnation den

- Page 852 and 853:

Chapter 17 | 827Disregarding potent

- Page 854 and 855:

at constant velocity in still air m

- Page 856 and 857:

Chapter 17 | 831TABLE 17-1Variation

- Page 858 and 859:

increase as the flow area of the du

- Page 860 and 861:

The ratio of the stagnation to stat

- Page 862 and 863:

Now we begin to reduce the back pre

- Page 864 and 865:

Another parameter sometimes used in

- Page 866 and 867:

Chapter 17 | 841Solution Nitrogen g

- Page 868 and 869:

Chapter 17 | 843P 0V i ≅ 0ThroatP

- Page 870 and 871:

Chapter 17 | 845(b) Since the flow

- Page 872 and 873:

The conservation of energy principl

- Page 874 and 875:

Chapter 17 | 849FIGURE 17-33Schlier

- Page 876 and 877:

Chapter 17 | 851The fluid propertie

- Page 878 and 879:

1 V 1,n A r 2 V 2,n A S r 1 V 1,n

- Page 880 and 881:

u, degrees504030201010 5Ma → 1 32

- Page 882 and 883:

where we must be careful to measure

- Page 884 and 885:

Chapter 17 | 859Analysis Because of

- Page 886 and 887:

1 V 1 r 2 V 2 (17-50)Chapter 17 |

- Page 888 and 889:

except for the narrow Mach number r

- Page 890 and 891:

Chapter 17 | 865Therefore, sonic co

- Page 892 and 893:

Also,P 0 P 0 P P* a 1 k 1 k>1k12M

- Page 894 and 895:

Chapter 17 | 869The maximum value o

- Page 896 and 897:

Analysis We denote the entrance, th

- Page 898 and 899:

Nozzles whose flow area decreases i

- Page 900 and 901:

17-24E Steam flows through a device

- Page 902 and 903:

17-77C Are the isentropic relations

- Page 904 and 905:

17-115E Steam enters a converging n

- Page 906:

17-154 Air is flowing in a wind tun