Couplings - Eoss.com

Couplings - Eoss.com

Couplings - Eoss.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

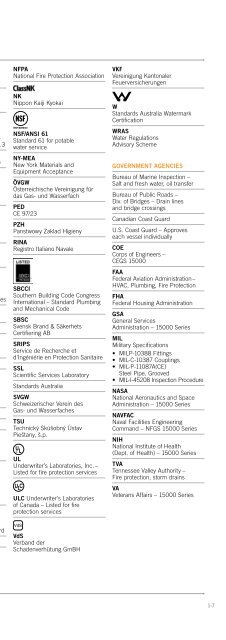

<strong>Couplings</strong>Flexible Coupling Systems and Performance §Standard flexible grooved-type couplings allow controlledangular, linear and rotational movement at each jointto ac<strong>com</strong>modate expansion/contraction (see note below),settling, vibration, noise and other piping system movement.These features provide advantages in designingpiping systems but must be considered when determininghanger and support spacing and location.Victaulic couplings offer superior vibration attenuationcharacteristics to both flexible metal and elastomericflexible arch-type connectors.Independent vibration testing data (request publication26.04) verifies that three Victaulic couplings in closeproximity to a vibration source (pump, equipment, etc.)provide superior vibration attenuation in piping systems.Both flexible and rigid couplings offer reduced constructionschedules, plus the convenience of a union at everyjoint and the proven pressure-responsive “C” shapedVictaulic gasket. Both type products fit into standardroll or cut grooved pipe and provide the security of fullcircumferential engagement of the coupling housing intothe groove for high pressure and end load service.SECTION 1: COUPLINGSNominalSizemmInchesSizeActualOutside DiametermmInchesAllow. PipeEndSep.† Deflect.Fr. C L †mmInchesDegreesper CouplingPipemm/mIn./Ft.20 26.9 0–1.63° 24'603/4 1.050 0 – 0.06 0.7225 33.7 0–1.62° 43'481 1.315 0–0.06 0.5732 42.4 0 – 1.62° 10'381 1/4 1.660 0 – 0.06 0.4540 48.3 0 – 1.61° 56'331 1/2 1.900 0–0.06 0.4050 60.3 0–1.61° 31'272 2.375 0 – 0.06 0.3265 73.0 0–1.61° 15'222 1/2 2.875 0–0.06 0.2676.1 mm76.1 0–1.61° 12'223.000 0 – 0.06 0.2680 88.9 0–1.61° 2'183 3.500 0–0.06 0.2290 101.6 0–1.60° 54'163 1/2 4.000 0 – 0.06 0.19108.0 mm108.0 0–3.21° 41'294.250 0–0.13 0.35100 114.3 0–3.21° 36'284 4.500 0–0.13 0.34120 127.0 0–3.21° 26'214 1/2 5.000 0 – 0.13 0.25133.0 mm133.0 0–3.21° 21'235.250 0–0.13 0.28139.7 mm139.7 0–3.21° 18'235.500 0–0.13 0.28125 141.3 0–3.21° 18'225 5.563 0–0.13 0.27152.4 mm152.4 0–3.21° 12'176.000 0 – 0.13 0.21NominalSizemmInches159.0 mmSizeActualOutside DiametermmInchesAllow. PipeEndSep.† Deflect.Fr. C L †mmInchesDegreesper CouplingPipemm/mIn./Ft.159.0 0–3.21° 9'206.250 0–0.13 0.24165.1 mm165.1 0–3.21° 6'196.500 0 – 0.13 0.23150 168.3 0–3.21° 5'196 6.625 0–0.13 0.23203.2 mm203.2 0–3.20° 54'138.000 0 – 0.13 0.16200 219.1 0–3.20° 50'158 8.625 0 – 0.13 0.18254.0 mm254.0 0–3.20° 43'1310.000 0 – 0.13 0.15250 273.0 0–3.20° 40'1210 10.750 0 – 0.13 0.14304.8 mm304.8 0–3.20° 36'1112.000 0 – 0.13 0.13300 323.9 0–3.20° 34'1012 12.750 0 – 0.13 0.12350 355.6 0–3.20° 31'914 @ 14.000 0 – 0.13 0.11375 381.0 0–3.20° 29'815 15.000 0 – 0.13 0.10400 406.4 0 – 3.20° 27'816 @ 16.000 0 – 0.13 0.10450 457.0 0–3.20° 24'718 @ 18.000 0 – 0.13 0.08500 508.0 0–3.20° 22'720 @ 20.000 0 – 0.13 0.08550 559.0 0–3.20° 19'622 22.000 0 – 0.13 0.07600 610.0 0–3.20° 18'624 @ 24.000 0 – 0.13 0.07§ Except for Style 72 outlet couplings. Contact Victaulic for details.† NOTE: These values are based on standard roll grooved pipe. Figures for standard cut grooved pipe may be doubled. See notes below.@ Allowable pipe end separation for Style W77 AGS flexible couplings in this size range are 3.1 – 9.5 mm/0.125 – 0.375".GENERAL NOTES:Working Pressure and End Load are total, from all internal andexternal loads, based on standard weight (ANSI) steel pipe, standardroll or cut grooved in accordance with Victaulic specifications.Contact Victaulic for performance on other pipe.Warning: For one time field test only, the Maximum JointWorkingPressuremaybeincreasedto1½timesthefiguresshown (except Style HP-70ES).Allowable Pipe End Separation and Deflection figuresshowthemaximum nominal range of movement available at each joint forstandard roll grooved pipe. Figures for standard cut grooved pipemay be doubled. These figures are maximums; for design andinstallation purposes these figures should be reduced by: 50%for 20–90mm/¾–3½"; 25% for 100mm/4" and larger.WWW.VICTAULIC.COM 1-15