Couplings - Eoss.com

Couplings - Eoss.com

Couplings - Eoss.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

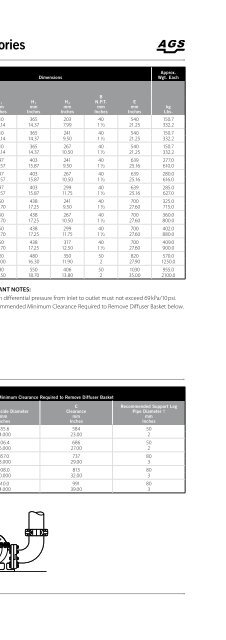

Pipe PreparationGroove DimensionsROLL GROOVESPECIFICATIONS NOTESFor Complete InformationRequest Publication 25.01ODBAExaggerated for Clarity@ Always refer to the I-100handbook for currentgrooving specifications.† On roll grooved pipe, AllowablePipe End Separation andDeflection from center linewill be ½ values listed forcut grooved pipe.# For non-AGS grooves in thissize refer to the I-100 pockethandbook for currentgrooving specifications.IMPORTANT NOTES:For roll grooving pipe from600–1200mm/24–48"contact Victaulic.Coatings applied to the interiorsurfaces, including bolt pad matingsurfaces, of our grooved and boltedplain end couplings should notexceed 0.25 mm/0.010". Also, thecoating thickness applied to thegasket seating surface and withinthe groove on the pipe exteriorshould not exceed 0.25 mm/0.010".GROOVE DIMENSION NOTES:SEE PG. 15-17BCDTSTANDARD ROLL GROOVE SPECIFICATIONS – STEEL AND OTHER METALLIC PIPE@†1 2 3 4 5 6 7 8NominalSizemmInchesDimensions – mm/InchesPipe Outside Diameter O.D.AGasket Seat± 0.76BGrv. Width± 0.76CGroove DiameterBasic Maximum Minimum ± 0.03 ± 0.03 Maximum MinimumDGrooveDepthref.TMinimumAllow.Wall Thk.MaximumAllow.FlareDiameter20 26.9 26.9 26.4 15.88 7.14 23.8 23.4 1.42 1.24 29.23/4 1.050 1.060 1.040 0.625 0.281 0.938 0.923 0.056 0.049 1.1525 33.7 33.7 33.1 15.88 7.14 30.2 29.9 1.60 1.24 36.31 1.315 1.328 1.302 0.625 0.281 1.190 1.175 0.063 0.049 1.4332 42.4 42.6 41.8 15.88 7.14 39.0 38.6 1.60 1.24 45.011/4 1.660 1.676 1.644 0.625 0.281 1.535 1.520 0.063 0.049 1.7740 48.3 48.7 47.8 15.88 7.14 45.1 44.7 1.60 1.24 51.11 1/2 1.900 1.919 1.881 0.625 0.281 1.775 1.760 0.063 0.049 2.0150 60.3 60.9 59.7 15.88 8.74 57.2 56.8 1.60 1.24 63.02 2.375 2.399 2.351 0.625 0.344 2.250 2.235 0.063 0.049 2.4865 73.0 73.8 72.3 15.88 8.74 69.1 68.6 1.98 1.98 75.72 1/2 2.875 2.904 2.846 0.625 0.344 2.720 2.702 0.078 0.078 2.9876.1 mm76.1 77.0 75.4 15.88 8.74 72.3 71.8 1.98 1.98 78.73.000 3.030 2.970 0.625 0.344 2.845 2.827 0.078 0.078 3.1080 88.9 89.8 88.1 15.88 8.74 84.9 84.5 1.98 1.98 91.43 3.500 3.535 3.469 0.625 0.344 3.344 3.326 0.078 0.078 3.6090 101.6 102.6 100.8 15.88 8.74 97.4 96.9 2.11 1.98 104.13 1/2 4.000 4.040 3.969 0.625 0.344 3.834 3.814 0.083 0.078 4.10108.0 mm108.0 109.0 107.2 15.88 8.74 103.7 103.2 2.11 1.98 110.54.250 4.293 4.219 0.625 0.344 4.084 4.064 0.083 0.078 4.35100 114.3 115.4 113.5 15.88 8.74 110.1 109.6 2.11 1.98 116.84 4.500 4.545 4.469 0.625 0.344 4.334 4.314 0.083 0.078 4.60120 127.0 128.3 126.2 15.88 8.74 122.8 122.3 2.11 1.98 129.541/2 5.000 5.050 4.969 0.625 0.344 4.834 4.814 0.083 0.078 5.10133.0 mm133.0 134.7 132.6 15.88 8.74 129.1 128.6 2.11 1.98 135.95.250 5.303 5.219 0.625 0.344 5.084 5.064 0.083 0.078 5.35139.7 mm139.7 141.1 138.9 15.88 8.74 135.5 135.0 2.11 1.98 142.25.500 5.556 5.469 0.625 0.344 5.334 5.314 0.083 0.078 5.60125 141.3 142.7 140.5 15.88 8.74 137.0 136.5 2.13 1.98 143.85 5.563 5.619 5.532 0.625 0.344 5.395 5.373 0.084 0.078 5.66152.4 mm159.0 mm152.4 153.8 151.6 15.88 8.74 148.1 147.5 2.16 1.98 154.96.000 6.056 5.969 0.625 0.344 5.830 5.808 0.085 0.078 6.10159.0 160.4 158.0 15.88 8.74 153.2 152.5 2.16 2.77 161.36.250 6.313 6.219 0.625 0.344 6.032 6.002 0.085 0.109 6.35165.1 mm165.1 166.7 164.3 15.88 8.74 160.8 160.2 2.16 2.77 167.66.500 6.563 6.469 0.625 0.344 6.330 6.308 0.085 0.109 6.60150 168.3 169.9 167.5 15.88 8.74 164.0 163.4 2.16 2.77 170.96 6.625 6.688 6.594 0.625 0.344 6.455 6.433 0.085 0.109 6.73200 219.1 220.7 218.3 19.05 11.91 214.4 213.8 2.34 2.77 223.58 8.625 8.688 8.594 0.750 0.469 8.441 8.416 0.092 0.109 8.80250 273.0 274.7 272.3 19.05 11.91 268.3 267.6 2.39 3.40 277.410 10.750 10.813 10.719 0.750 0.469 10.562 10.535 0.094 0.134 10.92300 323.9 325.5 323.1 19.05 11.91 318.3 317.5 2.77 3.96 328.212 12.750 12.813 12.719 0.750 0.469 12.531 12.501 0.109 0.156 12.9214 – 24350 – 600See AGS Grooving Chart, pg.15-18TABLE CONTINUED ON PG. 15-17SECTION 15: PIPE PREPARATIONWWW.VICTAULIC.COM 15-16