Couplings - Eoss.com

Couplings - Eoss.com

Couplings - Eoss.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

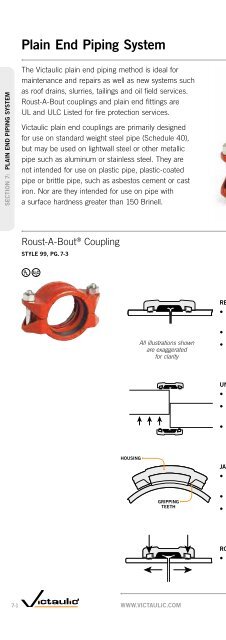

SECTION 3VIC/GUIDE-SPECVICTAULIC PRODUCT SPECIFICATIONThis Victaulic product specification was developed as a guide forwriting detailed piping specifications that address specific projectrequirements. Any references made regarding service applications,product usage, and installation practices, must be verified with thelatest Victaulic product literature. Contact Victaulic forinformation regarding specific applications not addressed in thisguide.CAUTION: USE VIC/GUIDE-SPEC FOR SELECTING AND SPECIFYING ONLY VictaulicPRODUCTS. DUE TO UNIQUE Victaulic PRODUCT CHARACTERISTICS,Victaulic SPECIFICATIONS, NOTED HEREIN, ARE NOT INTERCHANGEABLE WITHOTHER GROOVED PRODUCTS. USE OF INCOMPATIBLE PRODUCTS MAY RESULT INPERSONAL INJURY OR PROPERTY DAMAGE.Notice: Victaulic Company of America maintains a continual policy of productimprovement and, therefore, reserves the right to change productspecifications, designs and all data contained herein without noticeand without incurring obligation.The material presented in VIC/GUIDE-SPEC is intended as a referenceguide for the utilization of Victaulic products and is not intendedfor design purposes.Good piping practices should always prevail. Specific pressures,temperatures, external or internal loads, performance standards andtolerances must never be exceeded.Many applications require recognition of special conditions, coderequirements and use of safety factors. Qualified engineers mustmake these decisions and should refer to Victaulic Design Data andGasket Selection (publications 26.01 and 05.01) available at nocharge on request.While every effort has been made to ensure its accuracy, VictaulicCompany of America, its subsidiaries and affiliated <strong>com</strong>panies, makeno express or implied warranty of any kind respecting theinformation contained in VIC/GUIDE-SPEC or the materials referred totherein. Anyone making use of the information or material containedherein does so at his own risk and assumes any and all liabilityresulting from such use.All grooved <strong>com</strong>ponents (couplings, fittings, valves, gaskets, bolts, nuts)shall be of one manufacturer (Victaulic Company of America).Piping SoftwareThe Victaulic software solutions group helps to increasepiping project productivity by offering free softwarepackages to aid you in developing and drawing Victaulicpiping systems. In addition, Victaulic <strong>com</strong>ponents cannow be found in many of the major third party softwaredrawing packages listed below:THIRD PARTY SOFTWAREAveva (Cadcentre) PDMSBentley – AutoPlantBentley – PlantSpaceCEA Systems – Plant 4DCoade – CADWorx PipeHydratec – HydraCAD (Fire Protection)Intergraph PDSFind software online at www.victaulic.<strong>com</strong>/softwareDemos of our software packages can be downloadedfrom our website or the <strong>com</strong>plete software packagecan be ordered online in CD-ROM format. Visit ourwebsite to begin accessing our electronic services,or call 1-800-PICK-VIC.Vic-Blocks – designed specifically for AutoCAD users, Vic-Blocks 3Dis a dimensionally accurate, three-dimensional block library that wasdeveloped to assist with Victaulic piping system layouts. It includesblock symbols representing the main product line, drawn at full size.SECTION 17: PIPING SOFTWAREVic-BlocksBoth Vic-Blocks 2D andVic-Blocks 3D are <strong>com</strong>patiblewith the AutoCad two- andthree-dimensional library system.AutoCad is available free,to assist in drawing Victauliccouplings, fittings and valves.Demonstration modulesare available for viewingon our website.Vic-CellsDesigned specificallyfor MicroStation users,Vic-Cells is a dimensionallyaccurate 2D <strong>com</strong>pilationof cell libraries developedto assist with Victaulicpiping system layouts.Vic-PDS Piping SpecsVic-PDS piping specs area set of Integraph PlantDesign System (PDS) pipingspecifications, allowingusers to access and useVictaulic products in theirPDS piping systems design.Vic-PDMSPiping CatalogVic-PDMS Piping Catalogsis a set of Aveva (Cadcentre)plant design managementsystem (PDMS) catalogsthat allows users to accessand use Victaulic productsin their PDMS pipingsystems designs.Vic-Guide SpecSECTION 2VIC/GUIDE-SPECVICTAULIC PROD R USE WITH CARBON STEEL PIPE2.0 IPS Grooved Piping SysteVictaulic grooved mech tings, valves and othergrooved <strong>com</strong>ponents may be used as an option to welding, threading orflanged methods. All grooved <strong>com</strong>ponents shall be of one manufacturer(Victaulic Company of o local code approval.Victaulic products are permitted and/or Listed/Approved by codes orstandards organizations including but not limited to: ASME (B31.1, 31.3,31.9), ASTM, ANSI/AWWA (C-606), FM, IAPMO, International Code Council(IPC, IMC, IFC), NFPA S. Grooved end productmanufacturer to be ISO-9 couplings shall meet therequirements of ASTM F-12.1 Pipe/Grooved (StandCarbon Steel, A-53B/A-106B - Roll or cut grooved-ends as appropriate topipe material, wall thickness, pressures, size and method of joining.Pipe ends to be grooved in accordance with Victaulic current listedstandards conforming2.2 Victaulic Mechanica Carbon Steel Pipe<strong>Couplings</strong> shall be cast of ductile iron conforming to ASTM A-395, grade65-45-15, and ASTM A-536, Grade 65-45-122.2.a Mechanical <strong>Couplings</strong>Mechanical couplings shall be Victaulic Style 07 (Zero-Flex®) Rigidcoupling. Rigid couplings shall be of the angle pattern bolt padtype, and shall provide system support and hanging requirements inaccordance with ANSI B31.1, ANSI B31.4 and NFPA 13. Style HP-70Rigid coupling is for use in high pressure service applications.Victaulic Style 77 or 75 coupling shall be used where systemflexibility is desired. Noise and vibration reduction at mechanicalequipment connections is achieved by installing three style 77 or 75flexible couplings near the vibrations source.2.2.b Reducing Mechanical <strong>Couplings</strong>Use Victaulic Style 750 reducing couplings for direct reduction on2" (DN50) through 8" (DN200) pipe runs.2.2.c Snap-Joint® Quick Disconnect Mechanical CouplingWhere indicated on drawings, use Victaulic Style 78 Snap Joint®couplings for quick disconnect requirements.2.2.d Victaulic Boltless <strong>Couplings</strong>Where indicated on drawings, use Victaulic Style 791 boltlesscouplings for tamper resistant requirements.2.2.e Outlet Mechanical CouplingUse Victaulic Style 72 outlet couplings on header sizes 1-1/2"(DN40) through 6" (DN150) for grooved or threaded reduced outletsizes ½" (DN15) through 2" (DN50).2.2.f Mechanical Coupling BoltsMechanical Coupling bolts shall be zinc plated (ASTM B-633) heattreated carbon steel track head conforming to physical properties ofASTM A-183, minimum tensile strength 110,000 psi (758450 kPa) asprovided standard Victaulic. Optional Type 316 stainless steelVIC/GUIDE-SPECVICTAULIC PRODUCT SPECIFICATION FOR USE WITH STAINLESS STEE3.0 IPS Grooved Piping SystemVictaulic grooved mechanical pipe couplings, fittigrooved <strong>com</strong>ponents may be used as a proprietary system and/or as an optito welding, threading or flanged methods. All grooved <strong>com</strong>ponents shallof one manufacturer Victaulic Company of America, andcode approval and/or as listed by ANSI-B-31.1, B-31.3, B-31.9, ASME,UL/ULC, FM, IAPMO or ICC. Grooved end product manufacturer to be ISO-9001certified. Grooved couplings shall meet equirements of ASTM F-1476.3.1 Pipe/Grooved (Standard/Lightwall)Stainless Steel, ASTM A312 - Roll or cut grooved-ends as appropriate topipe material, wall thickness, pressures, size and method of joining.Pipe ends to be grooved in accordance with Victaulic current listedstandards conforming to ANSI/AWWA C-606.3.2 Victaulic Mechanical <strong>Couplings</strong> for Joining Stainless Steel PipeNote: Where design conditions require use of non-ferrous piping materialsfor both interior and exterior piping surfaces, Victaulic stainlesssteel couplings described in VIC/GUIDE-SPEC sections 3.2.a are tobe used.3.2.a Mechanical <strong>Couplings</strong>Shall be Style 489 Rigid Stainless Steel and Style 89 Rigid DuctileIron conforming to ASTM A-395 Grade 65-45-15 and ASTM A-536 Grade65-45-12. Styles 475 and 77-S Flexible Stainless Steel, type 316,conforming to ASTM A-351, A-743, and A-744 Grade CF-8M. Refer tocurrent Victaulic literature for pressure ratings for various pipesizes and pipe schedules.3.2.b Mechanical Coupling Bolts and NutsShall be Type 316 Stainless Steel, oval neck track bolts and heavyhex nuts with chemical and physical properties of ASTM A-193, GradeB8M, Class 2 or ASTM F-593, Group 2, Condition CW.Note: Where design conditions permit and where only interior pipingsurfaces require use of non-ferrous materials and where ferrousmaterials are acceptable for external piping surfaces, couplings andflange adapters described in VIC/GUIDE-SPEC sections 2.2, 2.3 and3.3 are to be used.3.3 Victaulic Flange Adapters3.3.a Vic-Flange Style 4412"-4" (DN50-DN150) for connection to ANSI class 125/150 flanged<strong>com</strong>ponents. Cast of stainless steel conforming to ASTM A-351, A-743and A-744. For larger sizes use the Style 45S Flanged AdapterNipple.3.3.b Vic-Flange® Style 7412"-24" (DN50-DN600) for connection to ANSI class 125/150 flanged<strong>com</strong>ponents. Cast of ductile iron conforming to ASTM A-395, grade65-45-15, and ASTM A-536, Grade 65-45-12. Refer to current Victaulicliterature for pressure ratings for various pipe sizes and pipeschedules.Vic-Guide Spec providestypical specifications formost Victaulic products.The data can be directlycut and pasted into yourspecifications. Vic-GuideSpec is available in PDFor Word format.*AutoCad is a registered trademark of Autodesk17-1WWW.VICTAULIC.COM