Couplings - Eoss.com

Couplings - Eoss.com

Couplings - Eoss.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

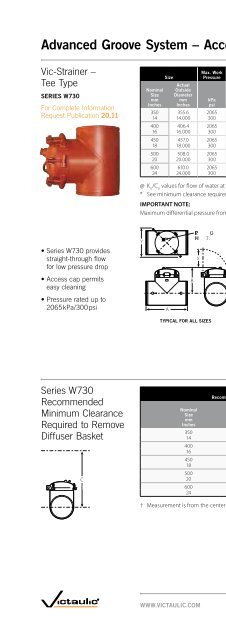

Pipe PreparationGroove DimensionsROLL GROOVESPECIFICATIONS NOTESFor Complete InformationRequest Publication 25.01ODBAExaggerated for Clarity@ Always refer to the I-100 handbook forcurrent grooving specifications.# Gasket Seat tolerances for sizes650–1050mm/26–42" are +0.8mmand -1.5 mm/+0.03" and -0.06".IMPORTANT NOTES:For roll grooving pipe from600–1200mm/24–48" contact Victaulic.Coatings applied to the interior surfaces,including bolt pad mating surfaces, of ourgrooved and bolted plain end couplingsshould not exceed 0.25 mm/0.010". Also,the coating thickness applied to the gasketseating surface and within the grooveon the pipe exterior should not exceed0.25 mm/0.010".BCDTSTANDARD ROLL GROOVE SPECIFICATIONS – STEEL AND OTHER METALLIC PIPE@†1 2 3 4 5 6 7 8NominalSizemmInchesDimensions – mm/InchesPipe Outside Diameter O.D.AGasket Seat± 0.76BGrv. Width± 0.76CGroove DiameterBasic Maximum Minimum ± 0.03 ± 0.03 Maximum MinimumTABLE CONTINUED FROM PG. 15-16GrooveDepthDref.TMin. Allow.WallThicknessMax.Allow.FlareDia.355.6 355.6 357.2 354.8 23.83 11.91 350.0 349.3 2.77 3.96 359.714 14.000 14.063 13.969 0.938 0.469 13.781 13.751 0.109 0.156 14.16377.0 mm377.0 379.4 376.2 23.83 11.91 371.1 370.4 2.94 4.50 381.014.843 14.937 14.811 0.938 0.469 14.611 14.581 0.116 0.177 15.0015"381.0 382.6 380.2 23.83 11.91 375.4 374.7 2.77 4.19 385.115.000 15.063 14.969 0.938 0.469 14.781 14.751 0.109 0.165 15.16406.4 406.4 408.0 405.6 23.83 11.91 400.8 400.1 2.77 4.19 410.516 16.000 16.063 15.969 0.938 0.469 15.781 15.751 0.109 0.165 16.16426.0 mm426.0 428.4 425.2 23.83 11.91 419.5 418.6 3.28 4.50 430.016.772 16.866 16.740 0.938 0.469 16.514 16.479 0.129 0.177 16.93457.0 457.0 458.8 456.4 25.40 11.91 451.6 450.9 2.77 4.78 461.318 18.000 18.063 17.969 1.000 0.469 17.781 17.751 0.109 0.188 18.16480.0mm480.0 482.4 479.2 25.40 11.91 473.1 472.2 3.45 5.99 484.118.898 18.992 18.867 1.000 0.469 18.626 18.591 0.136 0.236 19.06508.0 508.0 509.6 507.2 25.40 11.91 502.4 501.7 2.77 4.78 512.120 20.000 20.063 19.969 1.000 0.469 19.781 19.751 0.109 0.188 20.16530.0 mm530.0 532.4 529.2 25.40 11.91 522.5 521.6 3.73 5.99 534.220.866 20.960 20.835 1.000 0.469 20.572 20.537 0.147 0.236 21.03559.0 559.0 560.4 558.0 25.40 12.70 550.1 549.3 4.37 4.78 563.922 22.000 22.063 21.969 1.000 0.500 21.656 21.626 0.172 0.188 22.20610.0 610.0 611.2 608.8 25.40 12.70 600.9 600.1 4.37 5.54 614.724 24.000 24.063 23.969 1.000 0.500 23.656 23.626 0.172 0.218 24.20630.0 mm630.0 632.4 629.2 25.40 12.70 621.3 620.4 4.37 7.01 635.024.803 24.897 24.772 1.000 0.500 24.459 24.424 0.172 0.276 25.00650 660.4 662.8 659.6 45.45 15.88 647.7 646.1 6.35 6.35 665.526 # 26.000 26.093 25.969 1.75 0.625 25.500 25.437 0.250 0.250 26.20700 711.0 713.6 710.4 45.45 15.88 698.5 696.9 6.35 6.35 716.328 # 28.000 28.093 27.969 1.75 0.625 27.500 27.437 0.250 0.250 28.20750 762.0 764.4 761.2 45.45 15.88 749.3 747.7 6.35 6.35 767.130 # 30.000 30.093 29.969 1.75 0.625 29.500 29.437 0.250 0.250 30.20800 813.0 815.2 812.0 45.45 15.88 800.1 798.5 6.35 6.35 817.932 # 32.000 32.093 31.969 1.75 0.625 31.500 31.437 0.250 0.250 32.20900 914.0 916.8 913.6 45.45 15.88 901.7 900.1 6.35 6.35 919.536 # 36.000 36.093 35.969 1.75 0.625 35.500 35.437 0.250 0.250 36.201050 1067.0 1069.2 1066.0 50.80 15.88 1054.1 1052.5 6.35 6.35 1071.842 # 42.000 42.093 41.969 2.00 0.625 41.500 41.437 0.250 0.250 42.20SECTION 15: PIPE PREPARATIONGROOVE DIMENSION NOTES:Column 1: Nominal Pipe SizeColumn 2: Pipe Outside DiameterThe average pipe outside diameter must not vary from the specifications listed in thetables on the following pages. Maximum allowable pipe ovality should not vary bymore than 1%. Greater variations between the major and minor diameters will result indifficult coupling assembly. For carbon steel pipe, the maximum allowable tolerancefrom square-cut pipe ends is 0.8mm/0.030" for 20–90mm/¾–3½" sizes; 1.1mm/0.045"for 100–150 mm/4–6" sizes; and 1.5mm/0.060" for 200mm/8" and larger sizes. This ismeasured from the true square line. Any internal and external weld beads or seamsmust be ground flush to the pipe surface. The inside diameter of the pipe end must becleaned to remove coarse scale, dirt, and other foreign material that might interfere withor damage grooving rolls.Column 3: Gasket Seat “A” DimensionThe “A” dimension, or the distance from the pipe end to the groove, identifies the gasketseating area. This area must be free from indentations, projections (including weldseams), and roll marks from the pipe end to the groove to ensure a leak-tight seal forthe gasket. All oil, grease, and dirt must be removed.Column 4: Groove Width “B” DimensionThe “B” dimension, or groove width, controls expansion, contraction, and angulardeflection of flexible couplings by the distance it is located from the pipe and itswidth in relation to the coupling housings’ “key” width.Column 5: Groove Outside Diameter “C” DimensionThe “C” dimension is the proper diameter at the base of the groove. This dimension mustbe within the diameter’s tolerance and concentric with the OD for proper coupling fit.The groove must be of uniform depth for the entire pipe circumference.Column 6: Groove Depth “D” DimensionThe “D” dimension is the normal depth of the groove and is a reference for a “trial groove”only. Variations in pipe OD affect this dimension and must be altered, if necessary, tokeep the “C” dimension within tolerance. This groove must conform to the“C” dimension described above.Column 7: Minimum Allowable Wall Thickness “T” DimensionThe “T” dimension is the lightest grade (minimum, nominal wall thickness) of pipethat is suitable for cut or roll grooving. Pipe that is less than the minimum, nominalwall thickness for cut grooving may be roll grooved or adapted for Victaulic couplingsby using Vic-Ring adapters. Vic-Ring adapters can be used in the following situations(contact Victaulic for details):• When the pipe is less than the minimum, nominal wall thickness suitable for rollgrooving• When the pipe outside diameter is too large to roll or cut groove• When the pipe is used in abrasive servicesColumn 8: Maximum Allowable Pipe-End Flare Diameter “F” Dimension(Standard Roll Groove Only)Maximum allowable pipe-end flare diameter is measured at the extreme pipe-enddiameter.15-17WWW.VICTAULIC.COM