Feasibility of Fish Passage at Alameda Creek Diversion Dam

Feasibility of Fish Passage at Alameda Creek Diversion Dam

Feasibility of Fish Passage at Alameda Creek Diversion Dam

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

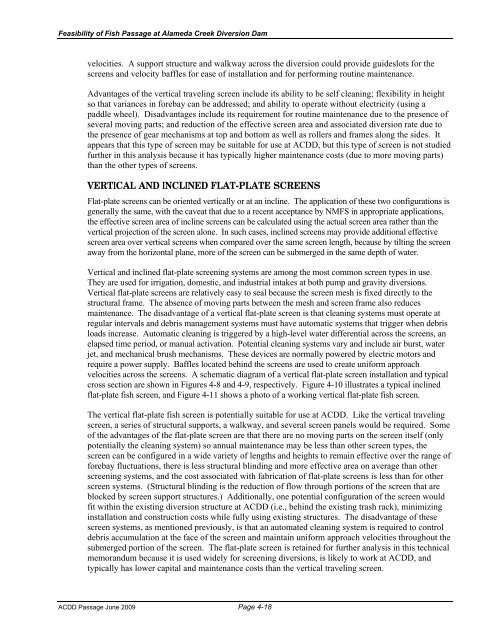

<strong>Feasibility</strong> <strong>of</strong> <strong>Fish</strong> <strong>Passage</strong> <strong>at</strong> <strong>Alameda</strong> <strong>Creek</strong> <strong>Diversion</strong> <strong>Dam</strong>velocities. A support structure and walkway across the diversion could provide guideslots for thescreens and velocity baffles for ease <strong>of</strong> install<strong>at</strong>ion and for performing routine maintenance.Advantages <strong>of</strong> the vertical traveling screen include its ability to be self cleaning; flexibility in heightso th<strong>at</strong> variances in forebay can be addressed; and ability to oper<strong>at</strong>e without electricity (using apaddle wheel). Disadvantages include its requirement for routine maintenance due to the presence <strong>of</strong>several moving parts; and reduction <strong>of</strong> the effective screen area and associ<strong>at</strong>ed diversion r<strong>at</strong>e due tothe presence <strong>of</strong> gear mechanisms <strong>at</strong> top and bottom as well as rollers and frames along the sides. Itappears th<strong>at</strong> this type <strong>of</strong> screen may be suitable for use <strong>at</strong> ACDD, but this type <strong>of</strong> screen is not studiedfurther in this analysis because it has typically higher maintenance costs (due to more moving parts)than the other types <strong>of</strong> screens.VERTICAL AND INCLINED FLAT-PLATE SCREENSFl<strong>at</strong>-pl<strong>at</strong>e screens can be oriented vertically or <strong>at</strong> an incline. The applic<strong>at</strong>ion <strong>of</strong> these two configur<strong>at</strong>ions isgenerally the same, with the cave<strong>at</strong> th<strong>at</strong> due to a recent acceptance by NMFS in appropri<strong>at</strong>e applic<strong>at</strong>ions,the effective screen area <strong>of</strong> incline screens can be calcul<strong>at</strong>ed using the actual screen area r<strong>at</strong>her than thevertical projection <strong>of</strong> the screen alone. In such cases, inclined screens may provide additional effectivescreen area over vertical screens when compared over the same screen length, because by tilting the screenaway from the horizontal plane, more <strong>of</strong> the screen can be submerged in the same depth <strong>of</strong> w<strong>at</strong>er.Vertical and inclined fl<strong>at</strong>-pl<strong>at</strong>e screening systems are among the most common screen types in use.They are used for irrig<strong>at</strong>ion, domestic, and industrial intakes <strong>at</strong> both pump and gravity diversions.Vertical fl<strong>at</strong>-pl<strong>at</strong>e screens are rel<strong>at</strong>ively easy to seal because the screen mesh is fixed directly to thestructural frame. The absence <strong>of</strong> moving parts between the mesh and screen frame also reducesmaintenance. The disadvantage <strong>of</strong> a vertical fl<strong>at</strong>-pl<strong>at</strong>e screen is th<strong>at</strong> cleaning systems must oper<strong>at</strong>e <strong>at</strong>regular intervals and debris management systems must have autom<strong>at</strong>ic systems th<strong>at</strong> trigger when debrisloads increase. Autom<strong>at</strong>ic cleaning is triggered by a high-level w<strong>at</strong>er differential across the screens, anelapsed time period, or manual activ<strong>at</strong>ion. Potential cleaning systems vary and include air burst, w<strong>at</strong>erjet, and mechanical brush mechanisms. These devices are normally powered by electric motors andrequire a power supply. Baffles loc<strong>at</strong>ed behind the screens are used to cre<strong>at</strong>e uniform approachvelocities across the screens. A schem<strong>at</strong>ic diagram <strong>of</strong> a vertical fl<strong>at</strong>-pl<strong>at</strong>e screen install<strong>at</strong>ion and typicalcross section are shown in Figures 4-8 and 4-9, respectively. Figure 4-10 illustr<strong>at</strong>es a typical inclinedfl<strong>at</strong>-pl<strong>at</strong>e fish screen, and Figure 4-11 shows a photo <strong>of</strong> a working vertical fl<strong>at</strong>-pl<strong>at</strong>e fish screen.The vertical fl<strong>at</strong>-pl<strong>at</strong>e fish screen is potentially suitable for use <strong>at</strong> ACDD. Like the vertical travelingscreen, a series <strong>of</strong> structural supports, a walkway, and several screen panels would be required. Some<strong>of</strong> the advantages <strong>of</strong> the fl<strong>at</strong>-pl<strong>at</strong>e screen are th<strong>at</strong> there are no moving parts on the screen itself (onlypotentially the cleaning system) so annual maintenance may be less than other screen types, thescreen can be configured in a wide variety <strong>of</strong> lengths and heights to remain effective over the range <strong>of</strong>forebay fluctu<strong>at</strong>ions, there is less structural blinding and more effective area on average than otherscreening systems, and the cost associ<strong>at</strong>ed with fabric<strong>at</strong>ion <strong>of</strong> fl<strong>at</strong>-pl<strong>at</strong>e screens is less than for otherscreen systems. (Structural blinding is the reduction <strong>of</strong> flow through portions <strong>of</strong> the screen th<strong>at</strong> areblocked by screen support structures.) Additionally, one potential configur<strong>at</strong>ion <strong>of</strong> the screen wouldfit within the existing diversion structure <strong>at</strong> ACDD (i.e., behind the existing trash rack), minimizinginstall<strong>at</strong>ion and construction costs while fully using existing structures. The disadvantage <strong>of</strong> thesescreen systems, as mentioned previously, is th<strong>at</strong> an autom<strong>at</strong>ed cleaning system is required to controldebris accumul<strong>at</strong>ion <strong>at</strong> the face <strong>of</strong> the screen and maintain uniform approach velocities throughout thesubmerged portion <strong>of</strong> the screen. The fl<strong>at</strong>-pl<strong>at</strong>e screen is retained for further analysis in this technicalmemorandum because it is used widely for screening diversions, is likely to work <strong>at</strong> ACDD, andtypically has lower capital and maintenance costs than the vertical traveling screen.ACDD <strong>Passage</strong> June 2009 Page 4-18