ethanol fuel production and use in kenya for sustainable ... - lumes

ethanol fuel production and use in kenya for sustainable ... - lumes

ethanol fuel production and use in kenya for sustainable ... - lumes

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

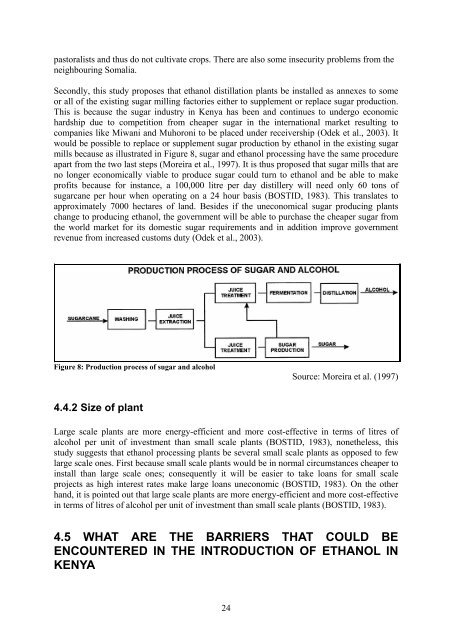

pastoralists <strong>and</strong> thus do not cultivate crops. There are also some <strong>in</strong>security problems from theneighbour<strong>in</strong>g Somalia.Secondly, this study proposes that <strong>ethanol</strong> distillation plants be <strong>in</strong>stalled as annexes to someor all of the exist<strong>in</strong>g sugar mill<strong>in</strong>g factories either to supplement or replace sugar <strong>production</strong>.This is beca<strong>use</strong> the sugar <strong>in</strong>dustry <strong>in</strong> Kenya has been <strong>and</strong> cont<strong>in</strong>ues to undergo economichardship due to competition from cheaper sugar <strong>in</strong> the <strong>in</strong>ternational market result<strong>in</strong>g tocompanies like Miwani <strong>and</strong> Muhoroni to be placed under receivership (Odek et al., 2003). Itwould be possible to replace or supplement sugar <strong>production</strong> by <strong>ethanol</strong> <strong>in</strong> the exist<strong>in</strong>g sugarmills beca<strong>use</strong> as illustrated <strong>in</strong> Figure 8, sugar <strong>and</strong> <strong>ethanol</strong> process<strong>in</strong>g have the same procedureapart from the two last steps (Moreira et al., 1997). It is thus proposed that sugar mills that areno longer economically viable to produce sugar could turn to <strong>ethanol</strong> <strong>and</strong> be able to makeprofits beca<strong>use</strong> <strong>for</strong> <strong>in</strong>stance, a 100,000 litre per day distillery will need only 60 tons ofsugarcane per hour when operat<strong>in</strong>g on a 24 hour basis (BOSTID, 1983). This translates toapproximately 7000 hectares of l<strong>and</strong>. Besides if the uneconomical sugar produc<strong>in</strong>g plantschange to produc<strong>in</strong>g <strong>ethanol</strong>, the government will be able to purchase the cheaper sugar fromthe world market <strong>for</strong> its domestic sugar requirements <strong>and</strong> <strong>in</strong> addition improve governmentrevenue from <strong>in</strong>creased customs duty (Odek et al., 2003).Figure 8: Production process of sugar <strong>and</strong> alcoholSource: Moreira et al. (1997)4.4.2 Size of plantLarge scale plants are more energy-efficient <strong>and</strong> more cost-effective <strong>in</strong> terms of litres ofalcohol per unit of <strong>in</strong>vestment than small scale plants (BOSTID, 1983), nonetheless, thisstudy suggests that <strong>ethanol</strong> process<strong>in</strong>g plants be several small scale plants as opposed to fewlarge scale ones. First beca<strong>use</strong> small scale plants would be <strong>in</strong> normal circumstances cheaper to<strong>in</strong>stall than large scale ones; consequently it will be easier to take loans <strong>for</strong> small scaleprojects as high <strong>in</strong>terest rates make large loans uneconomic (BOSTID, 1983). On the otherh<strong>and</strong>, it is po<strong>in</strong>ted out that large scale plants are more energy-efficient <strong>and</strong> more cost-effective<strong>in</strong> terms of litres of alcohol per unit of <strong>in</strong>vestment than small scale plants (BOSTID, 1983).4.5 WHAT ARE THE BARRIERS THAT COULD BEENCOUNTERED IN THE INTRODUCTION OF ETHANOL INKENYA24