ultima ultra multi-temp ultra xl extra optima with standard micro prior ...

ultima ultra multi-temp ultra xl extra optima with standard micro prior ...

ultima ultra multi-temp ultra xl extra optima with standard micro prior ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

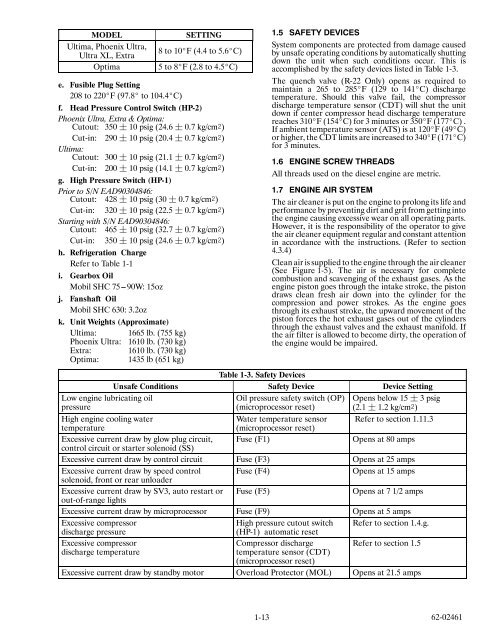

MODELUltima, Phoenix Ultra,Ultra XL, ExtraOptimaSETTING8to10_F (4.4to5.6_C)5to8_F (2.8to4.5_C)e. Fusible Plug Setting208 to 220_F (97.8_ to 104.4_C)f. Head Pressure Control Switch (HP-2)Phoenix Ultra, Extra & Optima:Cutout: 350 ¦ 10 psig (24.6 ¦ 0.7 kg/cm@)Cut-in: 290 ¦ 10 psig (20.4 ¦ 0.7 kg/cm@)Ultima:Cutout: 300 ¦ 10 psig (21.1 ¦ 0.7 kg/cm@)Cut-in: 200 ¦ 10 psig (14.1 ¦ 0.7 kg/cm@)g. High Pressure Switch (HP-1)Prior to S/N EAD90304846:Cutout: 428 ¦ 10 psig (30 ¦ 0.7 kg/cm@)Cut-in: 320 ¦ 10 psig (22.5 ¦ 0.7 kg/cm@)Starting <strong>with</strong> S/N EAD90304846:Cutout: 465 ¦ 10 psig (32.7 ¦ 0.7 kg/cm@)Cut-in: 350 ¦ 10 psig (24.6 ¦ 0.7 kg/cm@)h. Refrigeration ChargeRefer to Table 1-1i. Gearbox OilMobil SHC 75---90W: 15ozj. Fanshaft OilMobil SHC 630: 3.2ozk. Unit Weights (Approximate)Ultima: 1665 lb. (755 kg)Phoenix Ultra: 1610 lb. (730 kg)Extra: 1610 lb. (730 kg)Optima: 1435 lb (651 kg)Low engine lubricating oilpressure91.5 SAFETY DEVICESSystem components are protected from damage causedby unsafe operating conditions by automatically shuttingdown the unit when such conditions occur. This isaccomplished by the safety devices listed in Table 1-3.The quench valve (R-22 Only) opens as required tomaintain a 265 to 285_F (129 to 141_C) discharge<strong>temp</strong>erature. Should this valve fail, the compressordischarge <strong>temp</strong>erature sensor (CDT) will shut the unitdown if center compressor head discharge <strong>temp</strong>eraturereaches 310_F (154_C)for3minutesor350_F (177_C) .If ambient <strong>temp</strong>erature sensor (ATS) is at 120_F(49_C)or higher, the CDT limits are increased to 340_F (171_C)for 3 minutes.1.6 ENGINE SCREW THREADSAll threads used on the diesel engine are metric.1.7 ENGINE AIR SYSTEMThe air cleaner is put on the engine to prolong its life andperformance by preventing dirt and grit from getting intothe engine causing excessive wear on all operating parts.However, it is the responsibility of the operator to givethe air cleaner equipment regular and constant attentionin accordance <strong>with</strong> the instructions. (Refer to section4.3.4)Clean air is supplied to the engine through the air cleaner(See Figure 1-5). The air is necessary for completecombustion and scavenging of the exhaust gases. As theengine piston goes through the intake stroke, the pistondraws clean fresh air down into the cylinder for thecompression and power strokes. As the engine goesthrough its exhaust stroke, the upward movement of thepiston forces the hot exhaust gases out of the cylindersthrough the exhaust valves and the exhaust manifold. Ifthe air filter is allowed to become dirty, the operation ofthe engine would be impaired.Table 1-3. Safety DevicesUnsafe Conditions Safety Device Device SettingOil pressure safety switch (OP)(<strong>micro</strong>processor reset)Water <strong>temp</strong>erature sensor(<strong>micro</strong>processor reset)Fuse (F1)Opens below 15 ¦ 3psig(2.1 ¦ 1.2 kg/cm@)Refer to section 1.11.3High engine cooling water<strong>temp</strong>eratureExcessive current draw by glow plug circuit,Opens at 80 ampscontrol circuit or starter solenoid (SS)Excessive current draw by control circuit Fuse (F3) Opens at 25 ampsExcessive current draw by speed control Fuse (F4)Opens at 15 ampssolenoid, front or rear unloaderExcessive current draw by SV3, auto restart or Fuse (F5)Opens at 7 1/2 ampsout-of-range lightsExcessive current draw by <strong>micro</strong>processor Fuse (F9) Opens at 5 ampsExcessive compressorHigh pressure cutout switch Refer to section 1.4.g.discharge pressure(HP-1) automatic resetExcessive compressorRefer to section 1.5discharge <strong>temp</strong>eratureCompressor discharge<strong>temp</strong>erature sensor (CDT)(<strong>micro</strong>processor reset)Excessive current draw by standby motor Overload Protector (MOL) Opens at 21.5 amps1-13 62-02461