ultima ultra multi-temp ultra xl extra optima with standard micro prior ...

ultima ultra multi-temp ultra xl extra optima with standard micro prior ...

ultima ultra multi-temp ultra xl extra optima with standard micro prior ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

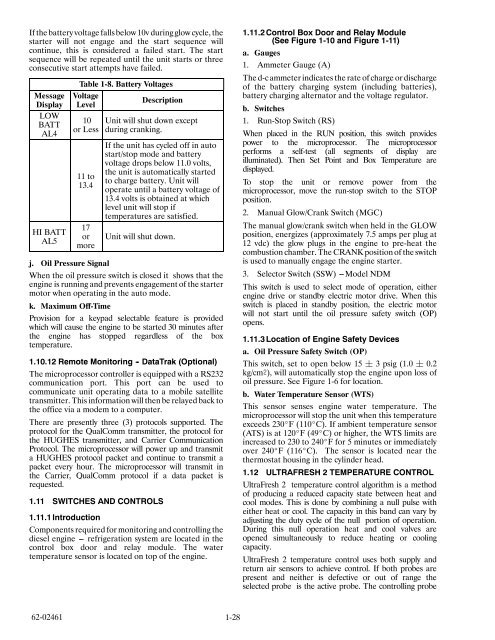

1.1.1 HEAT/COOL MODEIf the battery voltage falls below 10v during glow cycle, thestarter will not engage and the start sequence willcontinue, this is considered a failed start. The startsequence will be repeated until the unit starts or threeconsecutive start at<strong>temp</strong>ts have failed.MessageDisplayLOWBATTAL4HI BATTAL5Table 1-8. Battery VoltagesVoltageDescriptionLevel10or Less11 to13.417ormoreUnit will shut down exceptduring cranking.If the unit has cycled off in autostart/stop mode and batteryvoltage drops below 11.0 volts,the unit is automatically startedto charge battery. Unit willoperate until a battery voltage of13.4 volts is obtained at whichlevelunitwillstopif<strong>temp</strong>eratures are satisfied.Unit will shut down.j. Oil Pressure SignalWhen the oil pressure switch is closed it shows that theengine is running and prevents engagement of the startermotor when operating in the auto mode.k. Maximum Off-TimeProvision for a keypad selectable feature is providedwhich will cause the engine to be started 30 minutes afterthe engine has stopped regardless of the box<strong>temp</strong>erature.1.10.12 Remote Monitoring - DataTrak (Optional)The <strong>micro</strong>processor controller is equipped <strong>with</strong> a RS232communication port. This port can be used tocommunicate unit operating data to a mobile satellitetransmitter. This information will then be relayed back tothe office via a modem to a computer.There are presently three (3) protocols supported. Theprotocol for the QualComm transmitter, the protocol forthe HUGHES transmitter, and Carrier CommunicationProtocol. The <strong>micro</strong>processor will power up and transmita HUGHES protocol packet and continue to transmit apacket every hour. The <strong>micro</strong>processor will transmit inthe Carrier, QualComm protocol if a data packet isrequested.1.11 SWITCHES AND CONTROLS1.11.1 IntroductionComponents required for monitoring and controlling thediesel engine --- refrigeration system are located in thecontrol box door and relay module. The water<strong>temp</strong>erature sensor is located on top of the engine.1.11.2 Control Box Door and Relay Module(See Figure 1-10 and Figure 1-11)a. Gauges1. Ammeter Gauge (A)The d-cammeter indicates the rate of charge or dischargeof the battery charging system (including batteries),battery charging alternator and the voltage regulator.b. Switches1. Run-Stop Switch (RS)When placed in the RUN position, this switch providespower to the <strong>micro</strong>processor. The <strong>micro</strong>processorperforms a self-test (all segments of display areilluminated). Then Set Point and Box Temperature aredisplayed.To stop the unit or remove power from the<strong>micro</strong>processor, move the run-stop switch to the STOPposition.2. Manual Glow/Crank Switch (MGC)The manual glow/crank switch when held in the GLOWposition, energizes (approximately 7.5 amps per plug at12 vdc) the glow plugs in the engine to pre-heat thecombustion chamber. The CRANK position of the switchis used to manually engage the engine starter.3. Selector Switch (SSW) ---Model NDMThis switch is used to select mode of operation, eitherengine drive or standby electric motor drive. When thisswitch is placed in standby position, the electric motorwill not start until the oil pressure safety switch (OP)opens.1.11.3 Location of Engine Safety Devicesa. Oil Pressure Safety Switch (OP)This switch, set to open below 15 ¦ 3 psig (1.0 ¦ 0.2kg/cm@), will automatically stop the engine upon loss ofoil pressure. See Figure 1-6 for location.b. Water Temperature Sensor (WTS)This sensor senses engine water <strong>temp</strong>erature. The<strong>micro</strong>processor will stop the unit when this <strong>temp</strong>eratureexceeds 230_F (110_C). If ambient <strong>temp</strong>erature sensor(ATS) is at 120_F (49_C) or higher, the WTS limits areincreased to 230 to 240_F for 5 minutes or immediatelyover 240_F (116_C). The sensor is located near thethermostat housing in the cylinder head.1.12 ULTRAFRESH 2 TEMPERATURE CONTROLUltraFresh 2 <strong>temp</strong>erature control algorithm is a methodof producing a reduced capacity state between heat andcool modes. This is done by combining a null pulse <strong>with</strong>either heat or cool. The capacity in this band can vary byadjusting the duty cycle of the null portion of operation.During this null operation heat and cool valves areopened simultaneously to reduce heating or coolingcapacity.UltraFresh 2 <strong>temp</strong>erature control uses both supply andreturn air sensors to achieve control. If both probes arepresent and neither is defective or out of range theselected probe is the active probe. The controlling probe62-024611-28