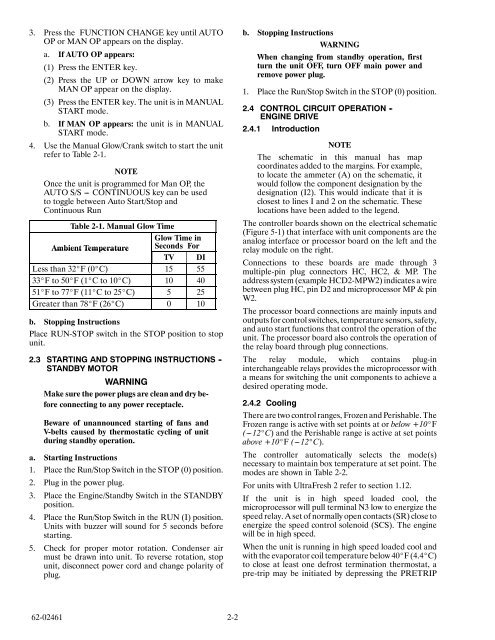

3. Press the FUNCTION CHANGE key until AUTOOP or MAN OP appears on the display.a. If AUTO OP appears:(1) Press the ENTER key.(2) Press the UP or DOWN arrow key to makeMAN OP appear on the display.(3) Press the ENTER key. The unit is in MANUALSTART mode.b. If MAN OP appears: the unit is in MANUALSTART mode.4. Use the Manual Glow/Crank switch to start the unitrefer to Table 2-1.NOTEOnce the unit is programmed for Man OP, theAUTO S/S --- CONTINUOUS key can be usedto toggle between Auto Start/Stop andContinuous RunTable 2-1. Manual Glow TimeGlow Time inAmbient Temperature Seconds ForTV DILess than 32_F (0_C) 15 5533_F to50_F (1_C to10_C) 10 4051_F to77_F (11_C to25_C) 5 25Greater than 78_F (26_C) 0 10b. Stopping InstructionsPlace RUN-STOP switch in the STOP position to stopunit.2.3 STARTING AND STOPPING INSTRUCTIONS -STANDBY MOTORWARNINGMake sure the power plugs are clean and dry beforeconnecting to any power receptacle.Beware of unannounced starting of fans andV-belts caused by thermostatic cycling of unitduring standby operation.a. Starting Instructions1. Place the Run/Stop Switch in the STOP (0) position.2. Plug in the power plug.3. Place the Engine/Standby Switch in the STANDBYposition.4. Place the Run/Stop Switch in the RUN (I) position.Units <strong>with</strong> buzzer will sound for 5 seconds beforestarting.5. Check for proper motor rotation. Condenser airmust be drawn into unit. To reverse rotation, stopunit, disconnect power cord and change polarity ofplug.b. Stopping InstructionsWARNINGWhen changing from standby operation, firstturn the unit OFF, turn OFF main power andremove power plug.1. Place the Run/Stop Switch in the STOP (0) position.2.4 CONTROL CIRCUIT OPERATION -ENGINE DRIVE2.4.1 IntroductionNOTEThe schematic in this manual has mapcoordinates added to the margins. For example,to locate the ammeter (A) on the schematic, itwould follow the component designation by thedesignation (I2). This would indicate that it isclosest to lines I and 2 on the schematic. Theselocations have been added to the legend.The controller boards shown on the electrical schematic(Figure 5-1) that interface <strong>with</strong> unit components are theanalog interface or processor board on the left and therelay module on the right.Connections to these boards are made through 3<strong>multi</strong>ple-pin plug connectors HC, HC2, & MP. Theaddress system (example HCD2-MPW2) indicates a wirebetween plug HC, pin D2 and <strong>micro</strong>processor MP & pinW2.The processor board connections are mainly inputs andoutputs for control switches, <strong>temp</strong>erature sensors, safety,and auto start functions that control the operation of theunit. The processor board also controls the operation ofthe relay board through plug connections.The relay module, which contains plug-ininterchangeable relays provides the <strong>micro</strong>processor <strong>with</strong>a means for switching the unit components to achieve adesired operating mode.2.4.2 CoolingThere are two control ranges, Frozen and Perishable. TheFrozen range is active <strong>with</strong> set points at or below +10_F( --- 12_C) and the Perishable range is active at set pointsabove +10_F ( --- 12_C).The controller automatically selects the mode(s)necessary to maintain box <strong>temp</strong>erature at set point. ThemodesareshowninTable2-2.For units <strong>with</strong> UltraFresh 2 refer to section 1.12.If the unit is in high speed loaded cool, the<strong>micro</strong>processorwillpullterminalN3lowtoenergizethespeed relay. A set of normally open contacts (SR) close toenergize the speed control solenoid (SCS). The enginewill be in high speed.When the unit is running in high speed loaded cool and<strong>with</strong> the evaporator coil <strong>temp</strong>erature below 40_F (4.4_C)to close at least one defrost termination thermostat, apre-trip may be initiated by depressing the PRETRIP62-024612-2

key. The operator now may verify the pre-trip sequence.(Refer to Section 1.10.8)As the trailer <strong>temp</strong>erature falls toward set point, the<strong>micro</strong>processor will place the unit in low speed loadedcool. The <strong>temp</strong>erature at which this occurs is not fixed butdepends upon the rate at which the trailer <strong>temp</strong>erature isapproaching set point.The speed relay (SR) de-energizes to open the circuit tothe speed control solenoid (SCS). Engine speeddecreases from high speed to low speed.As the trailer <strong>temp</strong>erature falls closer to set point, thecontroller will shift the operation from low speed loadedcool to low speed unloaded cool to further reduce coolingcapacity. To do this, the <strong>micro</strong>processor will pullterminals X2 or X2 & X3 low, completing the groundpath for the unloader relays (UFR & URR). The coilsenergizes to close the UFR & URR contacts. One or bothunloaders (UF and UR) may energize to unload thecompressor (Refer to Section 1.9).For setpoints above 10_F ( --- 12_C) and <strong>with</strong> decreasing<strong>temp</strong>erature, the unit will shift to low speed unloadedheat.For units <strong>with</strong> UltraFreeze refer to section 1.13.For units <strong>with</strong>out UltraFreeze setpoints below 10_F( --- 12_C) heating is locked out. Therefore, it is possiblefor the box <strong>temp</strong>erature to fall below setpoint in thefrozen range.Unit will remain in various stages of heating until the box<strong>temp</strong>erature increases enough to place the unit in the lowspeed unloaded cool mode. As the box <strong>temp</strong>eratureincreases, the unit will shift to low speed loaded cool , andthen to high speed cool mode (speed relay energizes).2.4.3 HeatingNOTES1. SV-3 will open after a 60 second delay, if theengine is in high speed and the differencebetween ambient and discharge <strong>temp</strong>eraturesexceeds 100_F (55.5_C). If the differencebetween ambient and discharge <strong>temp</strong>eraturesgoes below 50_F (27.8_C) SV-3 will close.2. SV-3 on Ultima’s, will not open when the ambient<strong>temp</strong>erature exceeds 80_F (26.7_C).3. Whenever the unit shifts to heat or defrost, HR1and HR2 energize simultaneously. Whenswitching from heat (or defrost) to cool, HR1de-energizes 2 seconds before HR2. This allowstime for SV-1 to open and clear the condenser ofliquid before SV4 closes. This will eliminate anyhigh pressure buildup which could occur. Duringthis time, only on the remote light bar, the heatand cool lights will be on together. The heat andcool display on the control panel changeimmediately.Refer to section 1.17 for description on heating cycle.For units <strong>with</strong> UltraFreeze refer to section 1.13.The unit will only heat when the controller is set above+10_F ( --- 12_C) as the heat relays are electronicallylocked out <strong>with</strong> set points at or below +10_F ( --- 12_C).The controller automatically selects the mode(s)necessary to maintain box <strong>temp</strong>erature at set point. Theheating modes are as follows <strong>with</strong> descending<strong>temp</strong>eratures:(a) Low Speed Unloaded Heating, (b) Low SpeedLoaded Heating, (c) High Speed Loaded HeatingThe controller will shift the unit into low speed unloadedheat when the trailer <strong>temp</strong>erature falls below set point(compressor in four cylinder heating). The<strong>micro</strong>processor pulls terminals N1, X1 and X2 low tocomplete the ground paths for the heat relays (HR1 andHR2) and unloader front relay (UFR). When theserelays energize, several things happen. This opens the(N.C.) contacts to the cool light and solenoid valve(SV2). SV2 now operates in conjunction <strong>with</strong> the headpressure control switch (HP2). (Refer to section 1.17)Also, HR1 closes a set of normally open contacts toenergize solenoid valve SV1 to close the condenser outletline.When the unloader front relay (UFR) energizes, a set ofN.O. contacts (UFR) close to energize the compressorfront unloader (UF). Compressor will be in four cylinderheating.Energizing HR2 closes two sets of N.O. contacts.Solenoid SV4 energizes and opens to allow hotrefrigerant vapor to enter the evaporator (section 1.17).The other set of HR2 contacts supply power to the heatlight on light bar.If more heating capacity is required, the unit will shift tolow speed loaded heating. The <strong>micro</strong>processor will breakthe ground path to de-energize the front unloader relay,which in turn, de-energizes the compressor unloaders(compressor shifts from four cylinder to six cylinderoperation).NOTEHigh speed heat is locked out for 5 minutesafter switching from cool to heat.When maximum heating capacity is required, the unitwill shift to high speed loaded heat. The <strong>micro</strong>processorenergizes the HR1, HR2, and speed relay (SR) coils.Terminals N1, X1 and N3 will be pulled low. The onlychange from the low speed loaded heat mode is that thespeed relay is now energized. SR contacts close toenergize the speed control solenoid (SCS). The enginewill be in high speed.2.4.4 DefrostRefer to sections 1.10.10 and 1.17 for the heat and defrostcycle.NOTEThe unit will be in high speed in the defrostmode.2-3 62-02461