AFMETCAL Newsletter - Wright-Patterson Air Force Base

AFMETCAL Newsletter - Wright-Patterson Air Force Base

AFMETCAL Newsletter - Wright-Patterson Air Force Base

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

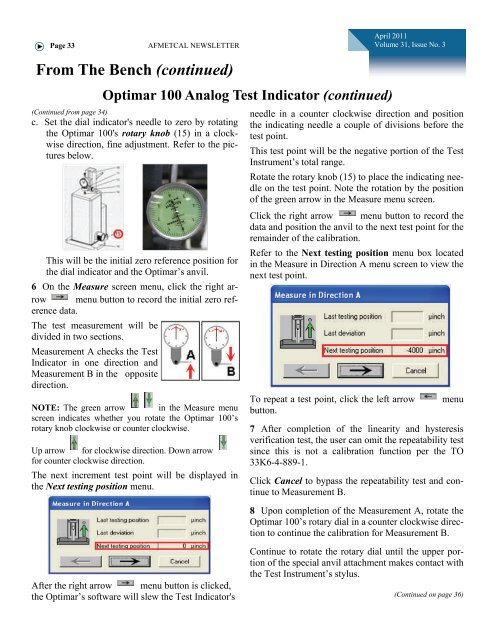

Page 33<strong>AFMETCAL</strong> NEWSLETTERApril 2011Volume 31, Issue No. 3From The Bench (continued)Optimar 100 Analog Test Indicator (continued)(Continued from page 34)c. Set the dial indicator's needle to zero by rotatingthe Optimar 100's rotary knob (15) in a clockwisedirection, fine adjustment. Refer to the picturesbelow.This will be the initial zero reference position forthe dial indicator and the Optimar’s anvil.6 On the Measure screen menu, click the right arrowmenu button to record the initial zero referencedata.The test measurement will bedivided in two sections.Measurement A checks the TestIndicator in one direction andMeasurement B in the oppositedirection.NOTE: The green arrow in the Measure menuscreen indicates whether you rotate the Optimar 100’srotary knob clockwise or counter clockwise.Up arrow for clockwise direction. Down arrowfor counter clockwise direction.The next increment test point will be displayed inthe Next testing position menu.needle in a counter clockwise direction and positionthe indicating needle a couple of divisions before thetest point.This test point will be the negative portion of the TestInstrument’s total range.Rotate the rotary knob (15) to place the indicating needleon the test point. Note the rotation by the positionof the green arrow in the Measure menu screen.Click the right arrow menu button to record thedata and position the anvil to the next test point for theremainder of the calibration.Refer to the Next testing position menu box locatedin the Measure in Direction A menu screen to view thenext test point.To repeat a test point, click the left arrowbutton.menu7 After completion of the linearity and hysteresisverification test, the user can omit the repeatability testsince this is not a calibration function per the TO33K6-4-889-1.Click Cancel to bypass the repeatability test and continueto Measurement B.8 Upon completion of the Measurement A, rotate theOptimar 100’s rotary dial in a counter clockwise directionto continue the calibration for Measurement B.After the right arrow menu button is clicked,the Optimar’s software will slew the Test Indicator'sContinue to rotate the rotary dial until the upper portionof the special anvil attachment makes contact withthe Test Instrument’s stylus.(Continued on page 36)