- Page 2 and 3:

Corporate HistoryIn 1981 Reitzel Sw

- Page 4 and 5:

TABLE OF CONTENTSWIRE ROPEGeneral I

- Page 6 and 7:

1 SECTION 1 - Wire RopeWIRE ROPEGen

- Page 8 and 9:

3 SECTION 1 - Wire Ropebeen applied

- Page 10 and 11:

5 SECTION 1 - Wire Ropeends will be

- Page 12 and 13:

7 SECTION 1 - Wire RopeTroubleshoot

- Page 14 and 15:

9 SECTION 1 - Wire RopeSuggested Wi

- Page 16 and 17:

11 SECTION 1 - Wire RopeRopesWire R

- Page 18 and 19:

13 SECTION 1 - Wire RopeSix Strand

- Page 20 and 21:

15 SECTION 1 - Wire RopeRotation Re

- Page 22 and 23:

17 SECTION 1 - Wire RopeGalvanized

- Page 24 and 25:

19 SECTION 1 - Wire RopeBethlehem8-

- Page 26 and 27:

21 SECTION 1 - Wire RopeBridonEndur

- Page 28 and 29:

23 SECTION 1 - Wire RopeBridonEndur

- Page 30 and 31:

25 SECTION 1 - Wire RopeWireco7-FLE

- Page 32 and 33:

27 SECTION 1 - Wire RopeSling Capac

- Page 34 and 35:

29 SECTION 1 - Wire RopeSling Capac

- Page 36 and 37:

31 SECTION 1 - Wire RopeTerminal Ef

- Page 38 and 39:

33 SECTION 2 - Elevator ProductsBet

- Page 40 and 41:

35 SECTION 2 - Elevator ProductsBet

- Page 42 and 43:

37 SECTION 2 - Elevator ProductsRee

- Page 44 and 45:

39 SECTION 2 - Elevator ProductsGov

- Page 46 and 47:

41 SECTION 2 - Elevator ProductsWir

- Page 48 and 49:

43 SECTION 3 - ChainCHAINTypes of C

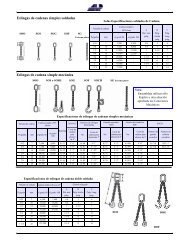

- Page 50 and 51:

45 SECTION 3 - ChainWelded Single C

- Page 52 and 53:

47 SECTION 3 - ChainWelded Quadrupl

- Page 54 and 55:

49 SECTION 3 - ChainCrosby ELIMINAT

- Page 56 and 57:

51 SECTION 3 - ChainKuplex ® II Ku

- Page 58 and 59:

53 SECTION 3 - ChainCrosby ® Grade

- Page 60 and 61:

55 SECTION 3 - ChainCrosby 8/10 TM

- Page 62 and 63:

57 SECTION 3 - ChainA-1355 Chain Ch

- Page 64 and 65:

59 SECTION 3 - ChainRecommended Cha

- Page 66 and 67:

61 SECTION 3 - ChainTable of WearCh

- Page 68 and 69:

63 SECTION 3 - ChainGrade 70 Transp

- Page 70 and 71:

65 SECTION 3 - ChainBinders & Chain

- Page 72 and 73:

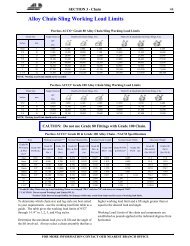

67 SECTION 4 - Mesh SlingsAlloy Cha

- Page 74 and 75:

69 SECTION 5 - Synthetic SlingsCons

- Page 76 and 77:

71 SECTION 5 - Synthetic SlingsSaf-

- Page 78 and 79:

73 SECTION 5 - Synthetic SlingsPenc

- Page 80 and 81:

75 SECTION 5 - Synthetic SlingsWeb

- Page 82 and 83:

77 SECTION 5 - Synthetic SlingsTypi

- Page 84 and 85: 79 SECTION 5 - Synthetic SlingsWeb

- Page 86 and 87: 81 SECTION 5 - Synthetic SlingsWeb

- Page 88 and 89: 83 SECTION 5 - Synthetic SlingsBrai

- Page 90 and 91: 85 SECTION 6 - Cargo ControlCARGO C

- Page 92 and 93: 87 SECTION 6 - Cargo ControlSafety

- Page 94 and 95: 89 SECTION 6 - Cargo ControlBuckle

- Page 96 and 97: 91 SECTION 6 - Cargo ControlWinches

- Page 98 and 99: 93 SECTION 6 - Cargo ControlFlat Ho

- Page 100 and 101: 95 SECTION 6 - Cargo Control“E”

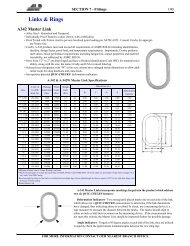

- Page 102 and 103: 97 SECTION 7 - FittingsG-450 Crosby

- Page 104 and 105: 99 SECTION 7 - FittingsG-429 Crosby

- Page 106 and 107: 101 SECTION 7 - FittingsG-340 & S-3

- Page 108 and 109: 103 SECTION 7 - FittingsScrew Pin S

- Page 110 and 111: 105 SECTION 7 - FittingsRound Pin S

- Page 112 and 113: 107 SECTION 7 - FittingsLarge Bolt

- Page 114 and 115: 109 SECTION 7 - FittingsS-320 & s-3

- Page 116 and 117: 111 SECTION 7 - FittingsShank HookS

- Page 118 and 119: 113 SECTION 7 - FittingsSHUR-LOC ®

- Page 120 and 121: 115 SECTION 7 - FittingsS-4320 HOOK

- Page 122 and 123: 117 SECTION 7 - FittingsSS-4055 Saf

- Page 124 and 125: 119 SECTION 7 - FittingsSpecialty H

- Page 126 and 127: 121 SECTION 7 - FittingsThimblesExt

- Page 128 and 129: 123 SECTION 7 - FittingsSlip-Thru T

- Page 130 and 131: 125 SECTION 7 - FittingsWedge Socke

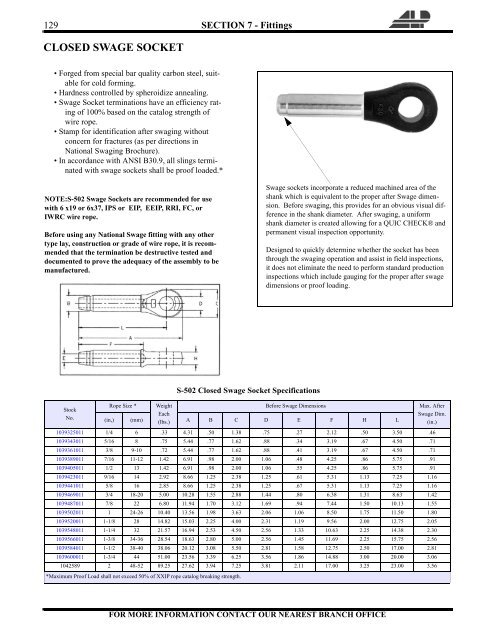

- Page 132 and 133: 127 SECTION 7 - FittingsClosed Spel

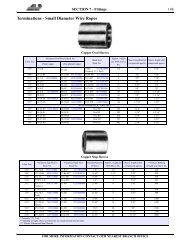

- Page 136 and 137: 131 SECTION 7 - FittingsTurnbuckles

- Page 138 and 139: 133 SECTION 7 - FittingsJaw & Eye T

- Page 140 and 141: 135 SECTION 7 - FittingsHook & Eye

- Page 142 and 143: 137 SECTION 7 - FittingsSwivelsEqui

- Page 144 and 145: 139 SECTION 7 - FittingsHoist Rings

- Page 146 and 147: 141 SECTION 7 - FittingsHeavy Duty

- Page 148 and 149: 143 SECTION 7 - FittingsEZ-Torque T

- Page 150 and 151: 145 SECTION 7 - FittingsElectroline

- Page 152 and 153: 147 SECTION 7 - FittingsTYPICAL ASS

- Page 154 and 155: 149 SECTION 7 - FittingsCable SizeN

- Page 156 and 157: 151 SECTION 7 - FittingsNicopress T

- Page 158 and 159: 153 SECTION 7 - FittingsStainless S

- Page 160 and 161: 155 SECTION 8 - BlocksBLOCKSWire Ro

- Page 162 and 163: 157 SECTION 8 - BlocksDiamond & Ova

- Page 164 and 165: 159 SECTION 8 - BlocksCrane Blocks#

- Page 166 and 167: 161 SECTION 8 - BlocksOverhaul Ball

- Page 168 and 169: 163 SECTION 8 - BlocksTackle Block

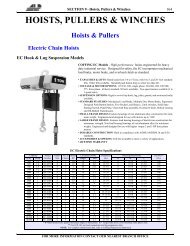

- Page 170 and 171: 165 SECTION 9 - Hoists, Pullers & W

- Page 172 and 173: 167 SECTION 9 - Hoists, Pullers & W

- Page 174 and 175: 169 SECTION 9 - Hoists, Pullers & W

- Page 176 and 177: 171 SECTION 9 - Hoists, Pullers & W

- Page 178 and 179: 173 SECTION 9 - Hoists, Pullers & W

- Page 180 and 181: 175 SECTION 9 - Hoists, Pullers & W

- Page 182 and 183: 177 SECTION 9 - Hoists, Pullers & W

- Page 184 and 185:

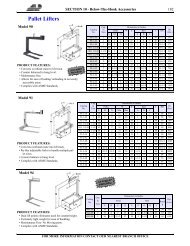

179 SECTION 10 - Below-the-Hook Acc

- Page 186 and 187:

181 SECTION 10 - Below-the-Hook Acc

- Page 188 and 189:

183 SECTION 10 - Below-the-Hook Acc

- Page 190 and 191:

185 SECTION 10 - Below-the-Hook Acc

- Page 192 and 193:

187 SECTION 10 - Below-the-Hook Acc

- Page 194 and 195:

189 SECTION 10 - Below-the-Hook Acc

- Page 196 and 197:

191 SECTION 10 - Below-the-Hook Acc

- Page 198 and 199:

193 SECTION 10 - Below-the-Hook Acc

- Page 200 and 201:

195 SECTION 10 - Below-the-Hook Acc

- Page 202 and 203:

197 SECTION 10 - Below-the-Hook Acc

- Page 204 and 205:

199 SECTION 10 - Below-the-Hook Acc

- Page 206 and 207:

201 SECTION 10 - Below-the-Hook Acc

- Page 208 and 209:

203 SECTION 10 - Below-the-Hook Acc

- Page 210 and 211:

205 SECTION 10 - Below-the-Hook Acc

- Page 212 and 213:

207 SECTION 11 -CordageNylonBlue St

- Page 214 and 215:

209 SECTION 11 -CordageRope Use Ref

- Page 216 and 217:

211 SECTION 12 - Fall RestraintUniv

- Page 218 and 219:

213 SECTION 12 - Fall RestraintSusp

- Page 220 and 221:

215 SECTION 13 - Marine ProductsMAR

- Page 222 and 223:

217 SECTION 13 - Marine ProductsLig

- Page 224 and 225:

219 SECTION 13 - Marine ProductsCha

- Page 226 and 227:

221 SECTION 13 - Marine ProductsDet

- Page 228 and 229:

223 SECTION 13 - Marine ProductsDJM

- Page 230 and 231:

225 SECTION 13 - Marine ProductsCle

- Page 232 and 233:

227 SECTION 13 - Marine ProductsPat

- Page 234 and 235:

229 SECTION 14- Tools & Miscellaneo

- Page 236 and 237:

231 SECTION 14- Tools & Miscellaneo

- Page 238 and 239:

233 SECTION 14- Tools & Miscellaneo

- Page 240 and 241:

235 SECTION 14- Tools & Miscellaneo

- Page 242 and 243:

237 SECTION 14- Tools & Miscellaneo